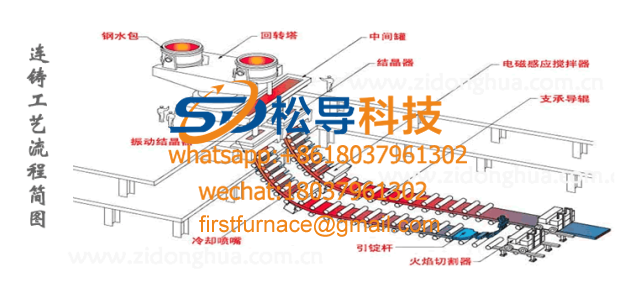

Continuous casting machine vibration device

Continuous casting machine vibration device continuous casting machine equipment

continuous casting machine equipment Straightening machine

Straightening machine Continuous casting machine shaker

Continuous casting machine shaker Continuous casting pusher

Continuous casting pusher Billet shearing device

Billet shearing device Tubing machine details

Tubing machine details Continuous casting machine crystallizer

Continuous casting machine crystallizer Continuous casting machine XF--II type straightening machine

Continuous casting machine XF--II type straightening machine continuous casting machine

continuous casting machine Continuous casting machine tundish

Continuous casting machine tundish Chartered in continuous casting machine

Chartered in continuous casting machine Continuous casting spindle and storage

Continuous casting spindle and storage Continuous casting hydraulic control system

Continuous casting hydraulic control system Continuous casting machine automatic water distribution facil

Continuous casting machine automatic water distribution facil Continuous casting machine automatic flame cutting car / auto

Continuous casting machine automatic flame cutting car / auto Continuous casting machine vibration device / continuous cast

Continuous casting machine vibration device / continuous cast Continuous casting machine round billet electromagnetic stirr

Continuous casting machine round billet electromagnetic stirr Continuous casting machine spindle bar continuous casting mac

Continuous casting machine spindle bar continuous casting mac Continuous casting machine, a first-class type II digital con

Continuous casting machine, a first-class type II digital conContact us will have a very low price, please consult the specific price. Firstfurnace@gmail.com

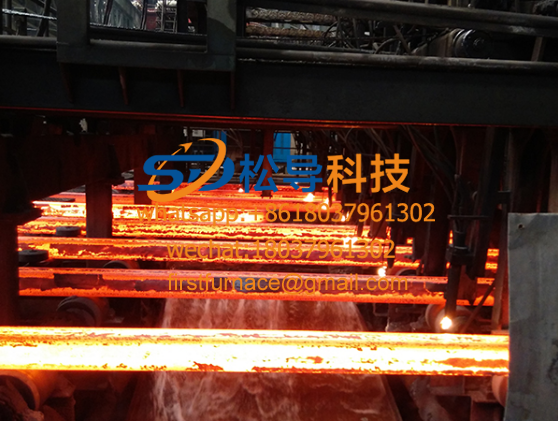

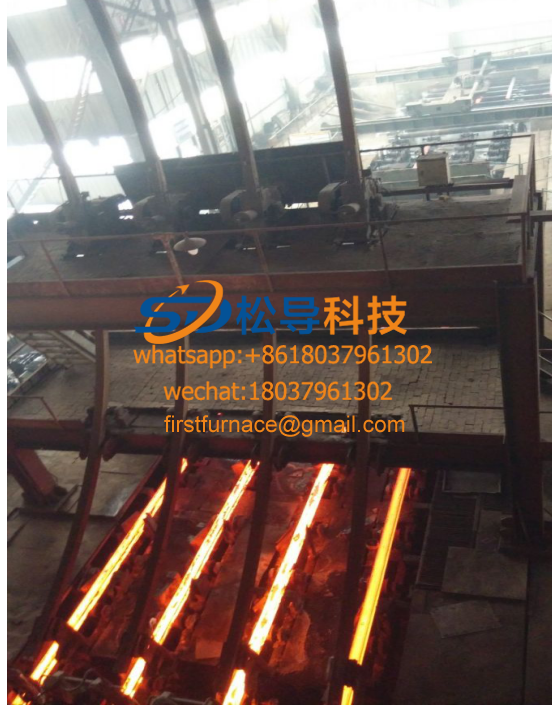

The crystallizer is a water-cooled ingot mold that is the core component of the mold and is called the heart of the continuous casting equipment. The molten steel is cooled in the crystallizer, preliminarily solidified, and uniformly formed into a shell having a certain thickness. The crystallizer is cooled by cooling water and is commonly referred to as primary cooling.

1. The tubular crystallizer is used, and the inner water jacket is a stainless steel integral water jacket to ensure the uniformity of the water joint.

2. The upper end of the copper tube is fixed by the key plate, and the lower end is free to adapt to the longitudinal expansion and contraction caused by the sharp change of the cold and hot copper tube. The fixing is firm and easy to disassemble.

3. The crystallizer is fastened on the frame of the vibrating device with quick release bolts. The positioning surface and the positioning pin are used for accurate and convenient positioning, accurate arc and quick replacement.

4. The inlet and outlet water is sealed by O-rings, which are automatically connected, convenient to install and reliable in positioning.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved