Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro

Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p

Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion  Ф108—Ф1016 steel pipe epoxy powder coating anti-corros

Ф108—Ф1016 steel pipe epoxy powder coating anti-corros Φ159-Φ219 steel pipe single layer epoxy powder coating ant

Φ159-Φ219 steel pipe single layer epoxy powder coating ant Φ60-Φ273 steel pipe outer wall epoxy powder coating produc

Φ60-Φ273 steel pipe outer wall epoxy powder coating produc Φ60-Φ219 steel pipe outer wall epoxy powder coating produc

Φ60-Φ219 steel pipe outer wall epoxy powder coating produc Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi

Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion

Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying

Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying  Φ48-Φ159 steel tube epoxy powder coating anti-corrosion pro

Φ48-Φ159 steel tube epoxy powder coating anti-corrosion proProcess requirements

Workpiece: Φ 159- Φ 219 × 12m steel pipe

Coating requirements: epoxy powder coating 300-400um

Process line speed: 2m/ min

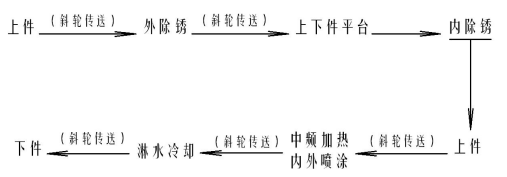

Process step

Main equipment introduction

1. 1 set of internal derusting production line

The equipment consists of belt sanding machine , steel sand recycling box and air intake system, transfer trolley, high pressure blasting tank and walking trolley, spray gun, hoist and sand storage tank.

Process introduction: Put the pipe on the turret trolley, let the trolley send the pipe head at one end into the steel sand recycling bin; start the blasting tank trolley, insert the lance head into the pipe, open the turret car to rotate the steel pipe, start the steel blasting Sand, spray to the other end, close the gun sanding valve. The blasting tank car retreats, allowing the compressed air to be purged inside the tube, and the steel sand is replenished by the sand storage tank to complete the whole process (the blasting speed is determined according to the diameter of the steel pipe). After the sprayed steel sand is recovered by the recovery tank, it will automatically flow to the belt sander and be transported by the belt to the other end of the hoist and lifted to the sand storage tank.

2. Powder coating equipment:

In the spraying operation, after the upper part of the workpiece, the inner spray gun is inserted into the steel pipe until the inlet position of the spray chamber, and the inclined wheel rotates to rotate the workpiece and advance horizontally. After the medium frequency is heated to 200 ° C and reaches the position of the spray chamber, the inner spray gun starts to work on the workpiece. Spraying is performed to solidify the powder using the heat of the workpiece. When the workpiece exits the spray chamber for about 1.5-2 minutes, it enters the shower cooling station. After cooling, it passes through the inclined wheel and is transferred to the lower part of the lower platform. After the workpiece is sprayed, the inner spray gun retreats by about 14m , and the upper part repeats the work.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved