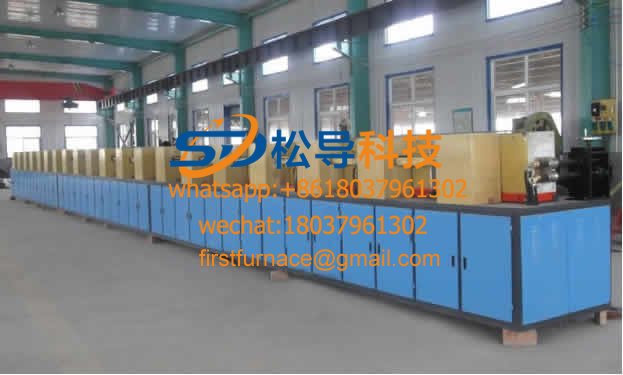

Induction heater for billet heating

Induction heater for billet heating Hot rolled billet induction heating equipment

Hot rolled billet induction heating equipment Inline induction billet heater

Inline induction billet heater Continuous billet heating furnace

Continuous billet heating furnace Continuous casting and rolling billet warming and heating pro

Continuous casting and rolling billet warming and heating pro Continuous casting billet induction heating furnace

Continuous casting billet induction heating furnace  Steel billet rolling equipment

Steel billet rolling equipment Billet online heating equipment

Billet online heating equipment billet online heating and heating electric furnace

billet online heating and heating electric furnace Billet online heating and heating furnace

Billet online heating and heating furnace Steel billet reheating equipment

Steel billet reheating equipment Steel billet warming and temperature compensation equipment

Steel billet warming and temperature compensation equipment Steel billet hot rolling production line

Steel billet hot rolling production line Steel billet heat treatment furnace

Steel billet heat treatment furnace Steel billet continuous casting and rolling heating furnace

Steel billet continuous casting and rolling heating furnace Billet continuous casting and rolling

Billet continuous casting and rolling Steel billet heating equipment

Steel billet heating equipment Billet induction reheating

Billet induction reheating Billet induction heating equipment

Billet induction heating equipment  Billet induction heating furnace

Billet induction heating furnaceContinuous casting and rolling billet secondary induction heating equipment can be used for:

The continuous casting billet (small billet, slab, round billet, rectangular billet) is heated in line before entering the rolling mill to realize continuous casting and rolling production.

The continuous casting cold billet is heated before rolling.

The steel pipe is heated before rolling.

The forgings are heated before forging.

First, the process parameters

1 , Continuous casting billet size: 6000 (length) × 150 (width) × 150 (thick)

2 , Online speed is up to 15m/min , speed adjustment range is 9~15m/min , each

The speed of the billet is constant.

3 , Temperature Distribution

( 1 ) The distribution of the temperature range of the continuous casting billet, the internal temperature belongs to the high temperature region, the temperature is 1100 ° C ; the outside is the low temperature region, the temperature is 800 ° C , and the low temperature region is the portion that needs to be increased by 300 ° C.

( 2 ), the temperature distribution characteristics of the head and tail of the continuous casting blank, usually the head temperature is lower than the tail temperature

About 50 ℃.

4 , the user needs to ensure that the squat: 30mm ; sickle bend: < 30mm

Second, the program design:

1. Heating capacity: the whole billet is heated to 1100 °C ;

2 , the average temperature capacity: through the induction heating furnace, to ensure that the temperature uniformity of the billet is better than the natural state before heating;

3 , medium frequency power supply

a ) According to the process index, from 800 ° C to 1100 ° C in 1 minute , the required heating power is rounded to 60 00 KW ;

b ) theoretical calculation of the power consumption of the billet is 38 degrees (such as heating 200 degrees Celsius, the power consumption of the billet is 25 degrees);

c ) In order to ensure the reliability of the continuous operation of the heating furnace, we divide the 60 00 KW intermediate frequency power supply into 2 sets of equipment, each of which is 30 00 KW and 1 for 1 standby;

d ) IF power supply parameter performance table:

Serial number | project | parameter | Remarks |

| 1 | Total power of the power supply | 5700KW | |

| 2 | Single power supply | 3000 KW | One use |

| 3 | Line voltage | 1000 KW | |

| 4 | Number of commutating pulses | 12 pulses | |

| 5 | IF voltage | 1600V | |

| 6 | IF frequency | 1200HZ | |

| 7 | Sensor voltage | 3200V |

4 , Induction heating furnace:

a ) According to the number of power supplies, it is determined that four induction furnaces (two and two) are used.

Two sets of one set, powered by an intermediate frequency power supply;

b ) Each set of two sets is placed between 3 pinch rolls with a roll spacing of 2.6 m. Two sets of pinch rolls are required for the inlet to the billet direction. The roll spacing is 1.6 m and the roll diameter is about 200 mm . The effective inductor is about 1 meter in length and the total length of the sensor is 1.2meters.

c ) Induction heating furnace internal space: billet is 150×150 billet, the inside of the inductor is also rounded square hole, the size is 280×280 , the thickness of refractory material is 20mm , and the net space around the billet and refractory material is 45mm ;

d ) The oxide rinsing ditch should be designed along the center line of the heating roller, the depth is larger than the cable ditch, and the unidirectional grading is carried out. The roller path is turned at the bottom of the slope to enter the scale pit and the saliva is regularly salvaged.

5 , The speed of the billet in the medium speed transmission zone must meet the 10 m safety distance from the medium speed to the slow speed . It is guaranteed that the speed of the billet has dropped to a slow and constant speed when entering the induction furnace.

6 , Two-point temperature measurement: the inlet constant velocity section is 7 meters away from the inlet , and a thermometer is set to detect the temperature of the billet to determine the temperature distribution, and select the appropriate intermediate frequency voltage. The inlet constant velocity section is1 meter away from the inlet . A trip switch is provided to start the intermediate frequency power supply boosting. A thermometer is placed at a distance of 1 m from the exit to display the heated temperature.

7 , Temperature control mode:

a) Using a simple segmentation selection mode, the temperature of the billet is segmented by a step of 50 °C starting from 700 °C , and each segment corresponds to a different intermediate frequency voltage (the intermediate frequency voltage corresponding to each segment is set by field test);

b) For example, if the billet temperature is in the range of 800-850 ° C , the intermediate frequency voltage is selected to be 1600 V ; the intermediate frequency voltage corresponding to 850-900 ° C is 1500 V , and the intermediate frequency voltage corresponding to 900-950 ° C is 1400 V , which is set in turn;

c) According to the control methods of ( 1 ) and ( 2 ), the temperature of the slab at the outlet of the heating furnace is theoretically at most 50 °C , that is, the temperature range is 1050-1100 °C ;

d) When the induction furnace is unloaded (no billet), the IF output voltage is automatically reduced to a minimum of approximately 200V for stable operation .

What is the use of the continuous casting and rolling billet heating and temperature compensation production line ?

Continuous casting and rolling slab warming and heating temperature production line is used for induction heating such as billet, billet, round billet, etc. Such equipment generally has other processes behind it, such as heating steel billets and rolling into steel bars and wire rods.

The price of continuous casting and rolling billet warming and heating production line

The industrial production line for continuous casting and rolling slab can be divided into cold billet heating furnace and billet, continuous casting and online reheating heating furnace according to different customer processes. The power of different equipment is different, and each customer The workpieces to be heated are also different, so the price of the equipment is not the same. When purchasing a continuous casting and rolling billet heating and temperature-compensating production line , you should first locate your own needs and find a larger, professional manufacturer.

How to accurately control the temperature of the continuous casting and rolling billet warming and heating line ?

Adopt two-point temperature measurement. In order to ensure the precise control of the temperature of the billet and the continuous casting billet during the heating process, an infrared thermometer is generally arranged at the inlet and the outlet. In addition, in order to make up for the time difference between the temperature measurement of the thermometer and improve the control sensitivity, a hot body detection device is installed at the inlet and the outlet of each group of furnaces, so that the heating furnace can be more sensitive and reliable in maintaining low power and high power switching without material and materials. .

How to choose the continuous casting and rolling billet warming and heating production line ?

The traditional steel rolling process is that the steel slabs obtained by steelmaking are cooled by stacking, transported to a rolling mill, and then heated by a heating furnace to be rolled into steel. This process has two drawbacks. First, the billet is pulled out from the steelmaking continuous casting machine and has a temperature of 700-900 ° C on the cold bed . The latent heat of the billet is not effectively utilized. Second, after the slab is heated by the heating furnace, the surface loss of the slab is about 1.5% due to oxidation loss . The steel-making workshop energy-saving and emission reduction technology transformation project implements continuous casting and rolling for the above problems, but the second point defect is still used in the regenerative heating furnace . In order to fully save energy, it is more suitable to carry out on-line heating and uniform temperature heating of the continuous casting billet byusing the continuous casting and rolling billet heating and temperature-increasing production line .

The role of continuous casting and rolling billet heating and temperature-increasing production line ?

The billet warming and heating furnace is a continuous casting billet (small billet, slab, round billet, rectangular billet) which is heated by the heating furnace before entering the rolling mill to realize continuous casting and rolling production. The heating capacity of the whole billet is heated to 1100 ° C , and the temperature uniformity is passed through the induction heating furnace to ensure that the temperature uniformity of the billet is better than the natural state before heating.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved