Flywheel ring gear high frequency quenching equipment

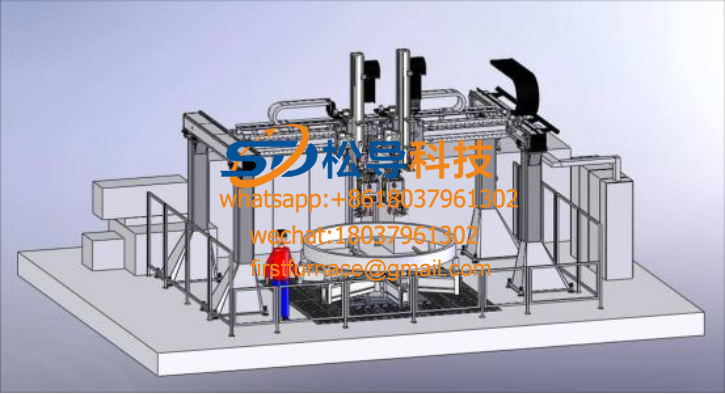

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

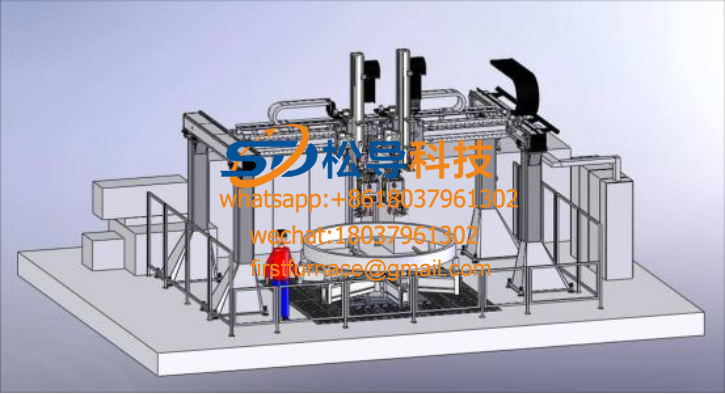

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

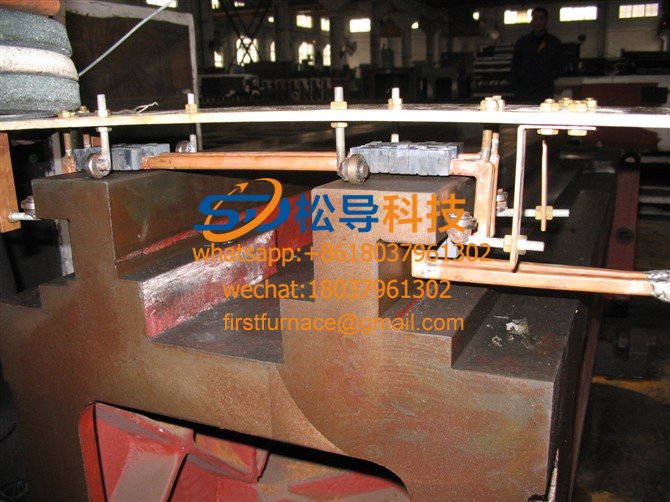

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentFlywheel ring gear high frequency quenching equipment

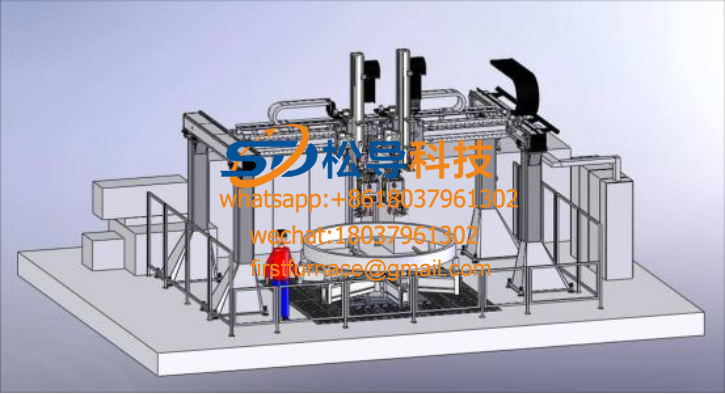

The working principle of the gear ring high frequency quenching equipment or the gear ring quenching machine tool for quenching the flywheel ring gear

The flywheel ring gear assembly is a connecting piece that transmits the power of the starter to the crankshaft. Its main function is to realize the power transmission between the starter and the crankshaft. It provides inertia for the engine. The flywheel is a disc with a large moment of inertia and is installed behind the crankshaft of the engine. On the end flange, a ring gear is pressed on the outer edge of the flywheel, which can mesh with the drive gear of the starter. At the same time, behind it is the power transmission between an engagement of the clutch. Grindability, high strength, high hardness and other high requirements, and the purpose of quenching is to improve the hardness and wear resistance of the workpiece. Therefore, most manufacturers use intermediate frequency quenching machines to quench the flywheel ring gear.

Brief introduction of gear ring high frequency quenching equipment:

Gear ring high-frequency hardening equipment or gear ring hardening machine tool uses electromagnetic induction technology. There are four methods for induction hardening of the gear ring: induction hardening along the tooth groove, tooth-by-tooth induction hardening, rotary induction hardening, and dual-frequency induction hardening. Among them, the induction hardening along the tooth groove and the tooth-by-tooth induction hardening process are particularly suitable for outer gear rings and inner gear rings with large diameters (up to 2.5m or more) and large modules, but not suitable for small diameter and small module gears (modules). The number is less than 6). The technician of Luoyang Songdao Induction Heating Technology Co., Ltd. said: When using induction hardening along the tooth groove for quenching, the common frequency is 1-30kHz, and the gap between the inductor and the part is controlled at 0.5-1mm. It is necessary to precisely control the inductor and the The two adjacent tooth flanks are very symmetrical, and the gap between the tooth flanks and the tooth root is strictly controlled.

The advantages of gear ring high-frequency quenching equipment / gear ring quenching machine tools:

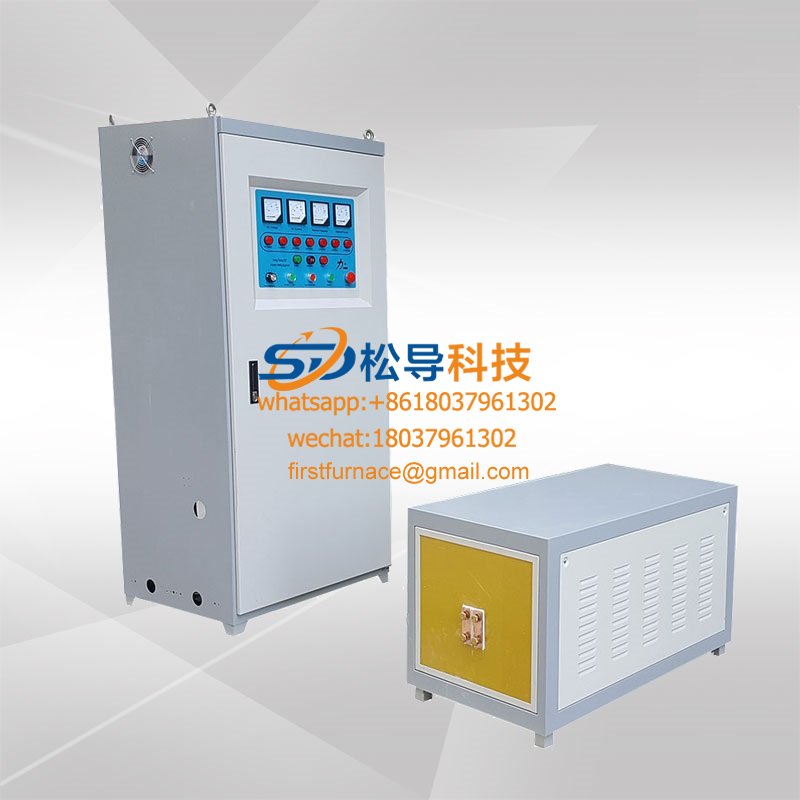

1. The equipment adopts IGBT power devices and unique frequency conversion technology, which is stable in operation and provides higher reliability and durability.

2. The step-up transformer that generates nearly ten thousand volts high voltage is eliminated, and the safety is very high.

3. Multi-purpose in one machine. It can complete heat treatment processes such as quenching, annealing, tempering, normalizing, and quenching and tempering, as well as welding, smelting, thermal assembly, thermal disassembly, and heat-through forming.

4. Environmental protection, no noise and dust, no waste smoke and waste gas, etc., which greatly improves the working environment of workers and enables workers to realize environmentally friendly production.

5. The gear ring high-frequency quenching equipment is light in weight, small in size, and simple to install. It can be completed in a few minutes by connecting to a 380V three-phase power supply, water inlet and water outlet.

6. The equipment does not need to be preheated before working, and it can work continuously.

PREV:Fully automatic gear high frequency quenching equipment

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved