Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro

Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p

Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion  Ф108—Ф1016 steel pipe epoxy powder coating anti-corros

Ф108—Ф1016 steel pipe epoxy powder coating anti-corros Φ159-Φ219 steel pipe single layer epoxy powder coating ant

Φ159-Φ219 steel pipe single layer epoxy powder coating ant Φ60-Φ273 steel pipe outer wall epoxy powder coating produc

Φ60-Φ273 steel pipe outer wall epoxy powder coating produc Φ60-Φ219 steel pipe outer wall epoxy powder coating produc

Φ60-Φ219 steel pipe outer wall epoxy powder coating produc Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi

Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion

Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying

Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying  Φ48-Φ159 steel tube epoxy powder coating anti-corrosion pro

Φ48-Φ159 steel tube epoxy powder coating anti-corrosion proProject Description:

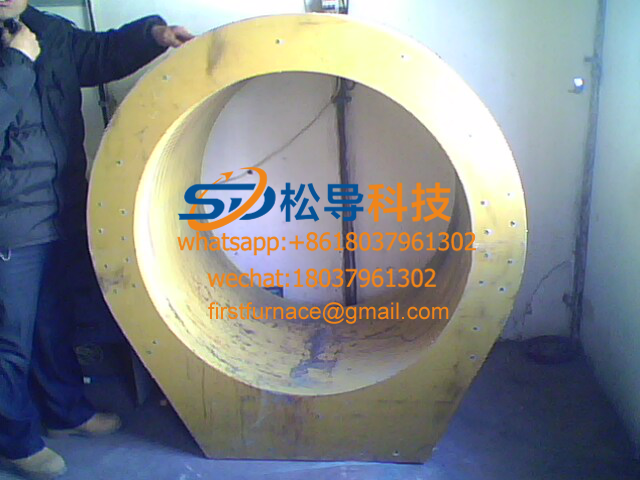

Ф 219 —Ф 1 2 19 Steel elbow double-layer epoxy powder coating anti-corrosion production line

Design Basis:

Elbow diameter: Ф 219 —Ф 1219

Radius of curvature : 4 to 6D

Process speed: 3 00 mm /min — 10 00 mm /min

Third, the conveyor roller

The process according to claim I Ф 219 -Ф 1219 double elbow anticorrosive epoxy powder coating production line is designed to roll a single tire to hang the power unit conveying roller raceway stable operation, low noise.

four Derusting machine selection :

This machine is specially used for shot blasting of the outer wall of steel pipe elbow to remove the scale on the surface and increase the surface area, increasing the coating adhesion.

V. Ф 219 —Ф 1 2 19 Steel elbow double-layer epoxy powder coating anti-corrosion production line IF power supply selection :

This production line is equipped with a 10 00 KW intermediate frequency heating device.

Six, Ф 219 —Ф 1 2 19 Steel elbow double-layer epoxy powder coating anti-corrosion production line dusting system selection :

1 , 8 gun control center DK type 4 sets

Each apparatus having the above automatic gun 8, a high-pressure spray gun is built, control cabinet 8 controls automatic spray gun voltage, current and gas system. And control 8 venturi powder pump powder supply system. Each apparatus above the fluidized bed containing the powder supply system 1 set, bed dimensions: 8Venturi toner supply pump (L × W × H) 800 × 775 × 570 (mm) containing.

Seven , air compressor and water sprinkler system :

This line is equipped with a 6 cubic screw air compressor, an air dryer 6 cubic, 1.0 cubic tank with a device for dusting (with three filters). The water sprinkler system is open and easy to adjust the roller table.

PREV:Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion production line

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved