Medium frequency quenching furnace

Medium frequency quenching furnace Shaft quenching machine

Shaft quenching machine Camshaft quenching machine

Camshaft quenching machine CNC quenching machine

CNC quenching machine ball head pin high frequency induction quenching furnace

ball head pin high frequency induction quenching furnace vertical shaft type high frequency quenching machine

vertical shaft type high frequency quenching machine vertical CNC induction hardening machine

vertical CNC induction hardening machine Piston rod quenching furnace

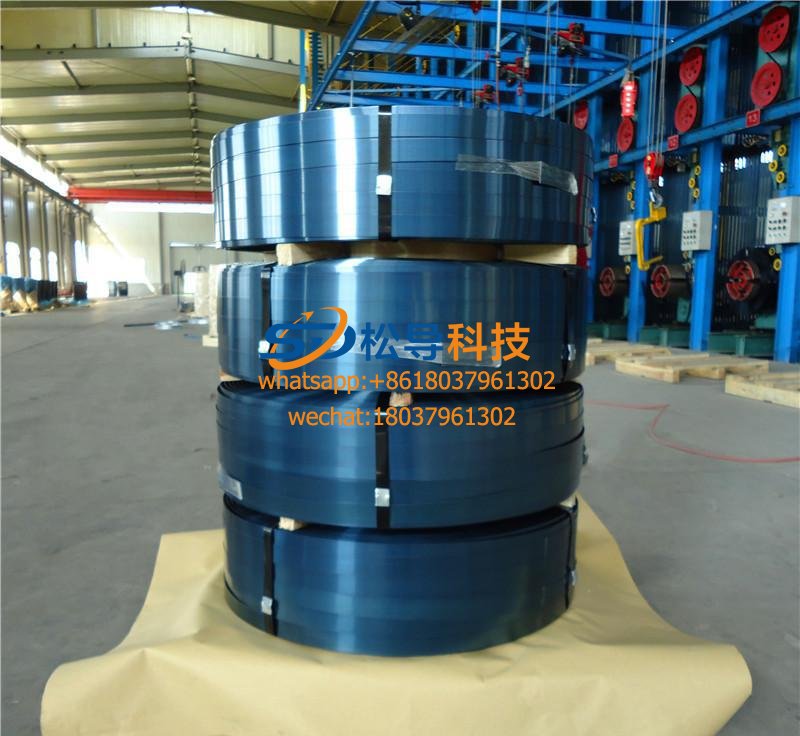

Piston rod quenching furnace Steel belt heating to blue induction heating equipment

Steel belt heating to blue induction heating equipment induction hardening machine tool

induction hardening machine tool gear quenching machine

gear quenching machine Rail Quenching Machine Tool

Rail Quenching Machine Tool half shaft induction hardening machine

half shaft induction hardening machineSD- 1200 quenching machine tool adopts advanced technology, 100- channel process quenching , high speed and low energy consumption. This product adopts advanced technology, 100- channel process quenching, high speed and low energy consumption. This product adopts advanced technology. Technology, 100- channel process quenching, fast speed, low energy consumption This product uses advanced technology, 100 processes quenching, fast speed, reducing energy consumption ...

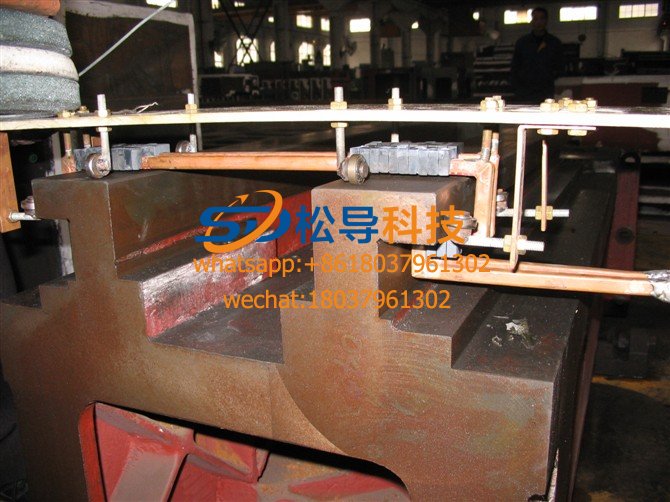

Detailed introduction:

The workpiece is quenched by means of workpiece movement, which is suitable for small-sized shafts, continuous moving quenching of disc parts, and overall heating and quenching. The quenching machine is divided into single-axis, double-axis, single-station, double-station and other structural forms. The parts arecontrolled by CNC numerical control system, and the high-intermediate frequency heating power supply is connected to realize the complete automation of the part quenching process. The quenching machine has continuous quenching, segmental continuous quenching, and simultaneous quenching.

General quenching machine performance characteristics:

1. Control by CNC numerical control system;

2 , quenching machine tool has continuous quenching, segmental continuous quenching, simultaneous quenching, segmentation and quenching and other processing methods;

3. The quenching machine adopts the single-station independent driving form to move the workpiece, and the various processing parameters of each station can be set separately;

4 , equipped with a main spray and auxiliary spray system, to meet the quenching process needs of some special parts, with a sufficient number of channels of quenching liquid and coolant interface;

5. The quenching machine is semi-automatic working mode: manual loading and unloading, and various timing actions (including protection functions) required for machine tool quenching are automatically completed;

6. The machining area on the upper part of the quenching machine and the lower drive and moving parts can be completely isolated in the structural design to ensure that the quenching liquid does not penetrate into the driving and moving parts, and naturally avoids the bad effect or damage of the sealing parts. The effect of quenching fluid on the drive and moving parts;

7. Multiple quenching programs can be stored for the user to call at any time.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved