Aluminum forging furnace

Aluminum forging furnace Aluminum rod medium frequency heating furnace

Aluminum rod medium frequency heating furnace Aluminum induction heating furnace

Aluminum induction heating furnace Aluminum hot rolling

Aluminum hot rolling Aluminum billet heating furnace

Aluminum billet heating furnace Aluminum billet induction heater

Aluminum billet induction heater aluminum alloy induction heating equipment

aluminum alloy induction heating equipment Aluminum ingot medium frequency heating furnace

Aluminum ingot medium frequency heating furnace Aluminum ingot online heating medium frequency furnace

Aluminum ingot online heating medium frequency furnace Trapezoidal aluminum ingot heating equipment

Trapezoidal aluminum ingot heating equipment Aluminum rod online heating furnace

Aluminum rod online heating furnace aluminum rod induction heating furnace

aluminum rod induction heating furnace Aluminum bar heating furnace

Aluminum bar heating furnace aluminum rod heating equipment

aluminum rod heating equipment Aluminum rod induction heating equipment

Aluminum rod induction heating equipment Aluminum bar induction heating furnace

Aluminum bar induction heating furnace Forging aluminum

Forging aluminum Alloy aluminum heating furnace

Alloy aluminum heating furnace Induction aluminum heating

Induction aluminum heating Trapezoidal aluminum ingot heating furnace

Trapezoidal aluminum ingot heating furnaceThe oxidation loss of the aluminum ingot heating medium aluminum ingot can be controlled below 0.05~0.5% , while the heating loss in the furnace is generally 2.5~3.0% , so the induction heating furnace generally does not need gas protection. The main body of the induction has only one inductor. This kind of furnace does not require a complicated piping system like a burning furnace, and does not require a burning furnace. It has a thick furnace wall, so it can be compactly organized in the production line or even combined. In other processing machines.

Aluminum ingot medium frequency heating furnace heating aluminum billet parameter summary

Aluminum billet size | Aluminum billet length | Heating temperature | Production capacity |

60 × 60mm | 3m-4m | 1150 | 25T/H |

75 × 75mm | 3m-4m | 1150 | 25T/H |

100 × 100mm | 2m | 1150 | 7T/H |

120 × 120mm | 1150 | 30T/H | |

120 × 120mm | 11.5-12.5m | 1150 | 90T/H |

125 × 125mm | 6m | 1150 | 8T/H |

125 × 125mm | 2m | 1150 | 7T/H |

130 × 130mm | 6m | 1150 | 50T/H |

135 × 135mm | 6m | 1150 | 100T/H |

150 × 150mm | 11.5-12.5m | 1150 | 70T/H |

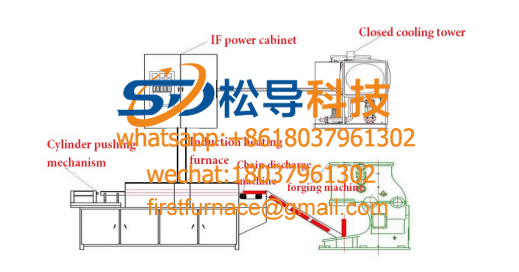

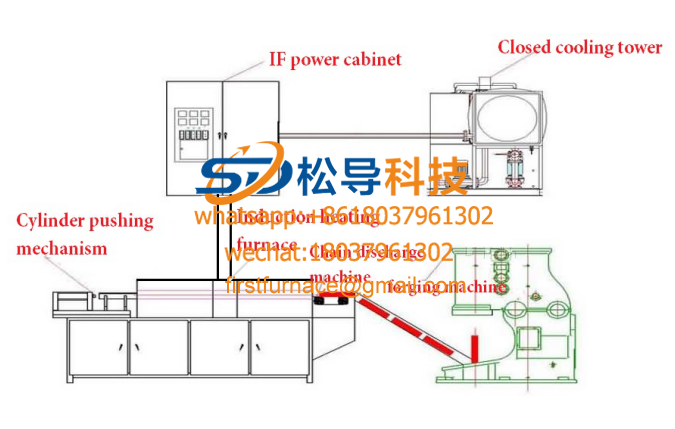

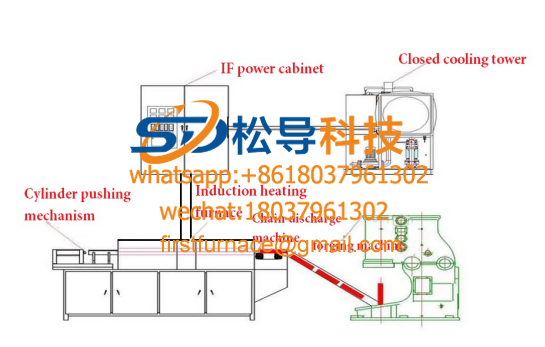

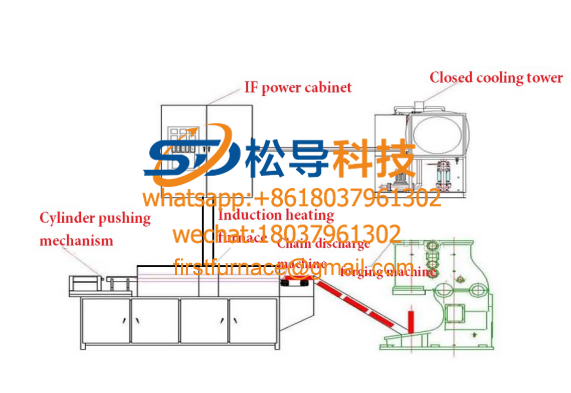

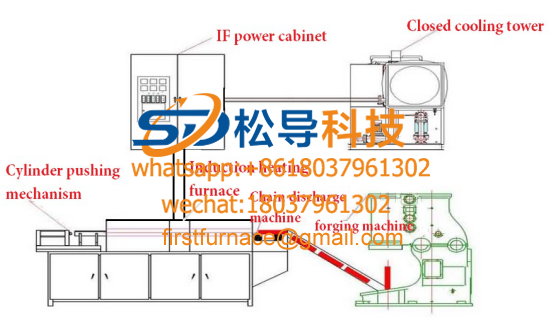

Aluminum ingot medium frequency heating furnace application assembly drawing

What parameters are required for the selection of aluminum indium medium frequency heating furnace ?

The selection of aluminum indium intermediate frequency heating furnace generally requires the following parameters:

First: the shape of the heated aluminum ingot, the outer dimensions, the weight of the workpiece being heated.

Second: the material material of the heated workpiece (generally induction heating, only for metal conductor materials).

Third: the time of the target temperature required for heating the heated workpiece, and the target temperature.

Once the above three points are clear, the bar heating furnace can be selected including matching power.

What are the characteristics of the aluminum indium medium frequency heating furnace structure?

1. Furnace structure: Our company's heating furnace is designed as an overall quick change type. Quick change is possible when changing the furnace body for different heated workpieces.

2. Furnace lining: The lining is made of silicon carbide or integral knotting, and the temperature is above 1450 °C.

3. Protection: Automatic shutdown when the water temperature exceeds 65 °C.

4. Induction furnace water cooling rail: Water-cooled rail is installed on the induction furnace lining.

How to calculate the power of aluminum indium medium frequency heating furnace ?

P=(0.168×200×693)/(0.24×0.6×145)=1029KW In the formula: 0.168—the average specific heat of the ferrous metal; 2080—the mass of the workpiece (Kg); 200—the temperature rise of the workpiece heating; 0.24— Work heat equivalent; 0.6 - average efficiency (0.6 in this case, generally 0.5 ~ 0.65, lower profile sensor, take 0.4); 145 - work beat (seconds)

According to the above calculation, a 1KHz induction heating device with a rated power of 1500 KW can be configured to meet the needs.

How to choose and choose aluminum indium medium frequency heating furnace ? Mainly from several aspects:

1. Shape and size of the heated workpiece

For large workpieces, bar stocks and solid materials, bar heating furnaces with relatively high power and low frequency should be used; for small workpieces, pipes, plates, gears, etc., the bar heating furnace with relatively low power and high frequency is used.

2. Depth and area required for heating

The heating depth is deep, the area is large, and the whole heating should be selected. The bar heating furnace with high power and low frequency should be selected; the heating depth is shallow, the area is small, local heating, and the bar heating furnace with relatively low power and high frequency is selected.

3, the required heating rate

The required heating speed is fast, and a bar heating furnace with relatively large power and relatively high frequency should be selected.

4, the continuous working time of the equipment

The continuous working time is long, and the bar heating furnace with a slightly larger power is used.

5, the connection distance between the sensing component and the device

The connection length is long, and even the use of water-cooled cable connection is required. The medium-frequency induction heating furnace with higher power should be used relatively.

6, process requirements

In general, quenching, welding and other processes, relatively power can be selected smaller, frequency selection is higher; annealing, tempering and other processes, relative power selection is larger, frequency selection is lower; red punch, hot calcination, smelting, etc., need For a heating process, the power should be chosen to be larger and the frequency selected lower.

7, the material of the workpiece

The relative power of the high melting point of the metal material is larger, the relative power of the lower melting point is smaller, the power of the smaller resistivity is larger, and the power of the larger resistivity is smaller.

Characteristics of aluminum indium medium frequency heating furnace :

1. The operation panel adopts color liquid crystal display, large-size touch screen, high-definition operation screen, and operation safety protection system, even for the first time users can operate with peace of mind.

2 , high heating temperature: according to the material of the workpiece to be heated, the length of heating time, can reach any temperature, can heat any metal;

3 , high efficiency and energy saving: energy conversion rate is higher than 85% , twice the old medium frequency induction heating equipment;

4 、Automatic control: It can adjust the power and time of heating and heat preservation process, which is beneficial to improve the thermal quality and heating repeatability, and can also work continuously for 24 hours;

5 , high reliability: This machine has a perfect protection circuit, when the power supply voltage, water pressure, water temperature, load current and other parameters can not meet the requirements, the machine will automatically stop working;

6 , aluminum forging heating furnace installation is simple: just connect the power supply and water;

7. The aluminum indium medium frequency heating furnace is small in size and safe and convenient to operate.

Aluminum ingot medium frequency heating furnace price:

The price of aluminum indium medium frequency heating furnace is about 10,000 yuan per unit, and there are several tens of thousands of expensive. The price of aluminum indium intermediate frequency heating furnace is affected by many aspects, such as brand, category, specification and market. It is necessary to understand and compare in many aspects before choosing to buy.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved