Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro

Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p

Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion  Ф108—Ф1016 steel pipe epoxy powder coating anti-corros

Ф108—Ф1016 steel pipe epoxy powder coating anti-corros Φ159-Φ219 steel pipe single layer epoxy powder coating ant

Φ159-Φ219 steel pipe single layer epoxy powder coating ant Φ60-Φ273 steel pipe outer wall epoxy powder coating produc

Φ60-Φ273 steel pipe outer wall epoxy powder coating produc Φ60-Φ219 steel pipe outer wall epoxy powder coating produc

Φ60-Φ219 steel pipe outer wall epoxy powder coating produc Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi

Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion

Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying

Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying  Φ48-Φ159 steel tube epoxy powder coating anti-corrosion pro

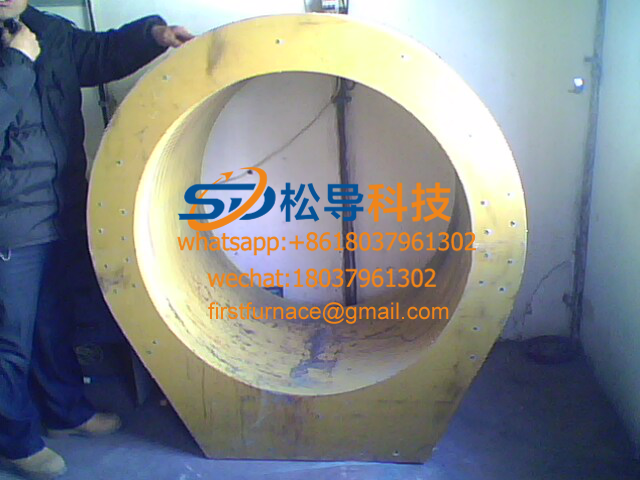

Φ48-Φ159 steel tube epoxy powder coating anti-corrosion proФ219—Ф820 steel pipe epoxy powder coating anti-corrosion production line

First, the project content:

Ф219—Ф820 inner and outer epoxy spray anti-corrosion production line

Second, the design basis:

Steel pipe diameter: Ф219—Ф820

Coating thickness: 300-500μ

Steel pipe length: 8000mm

Process speed: 3000mm/min-6000mm/min

Third, the pipeline conveyor

According to the user's requirements, our company's Ф219-Ф820 steel inner and outer epoxy spray anti-corrosion production line is designed as a transmission line with a single wheel as the power unit, which makes the pipeline running speed more stable.

Fourth, the descaling machine:

The new steel pipe outer wall treatment equipment can remove the rust and scale on the surface of the steel pipe, completely meet the cleaning requirements before the outer wall of the steel pipe is coated, and can meet the cleaning requirements of the outer wall of the small and medium-sized engineering steel pipe.

Five, medium frequency heating system:

This production line is equipped with two intermediate frequency heating devices of 350KW and 800KW.

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion production line IF power supply 350kw parameter selection :

name | parameter | name | parameter |

Input voltage | 380V | Output maximum voltage | 780V |

Input Current | 580A | Output maximum current | 700A |

Input frequency | 50HZ | Output frequency | 500HZ~800HZ |

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion production line IF power 800kw parameter parameter selection :

name | parameter | name | parameter |

Input voltage | 380V | Output maximum voltage | 780V |

Input Current | 1330A | Output maximum current | 1600A |

Input frequency | 50HZ | Output frequency | 500HZ~800HZ |

Sixth, Ф219-Ф820 steel pipe epoxy powder coating anti-corrosion production line powder spraying system:

8 gun control center. DK type 2 sets Each set contains 8 automatic spray guns, the spray gun is built-in high pressure, and the control cabinet controls the voltage, current and pneumatic system of 8 automatic spray guns. And control 8 venturi powder pump powder supply system.

Each set of the above devices contains a fluidized bed powder supply system. The size of the fluidized bed: (L × W × H) 800 × 775 × 570 (mm) contains 8 venturi powder supply pumps.

VII, Ф219-Ф820 steel pipe epoxy powder coating anti-corrosion production line water cooling room:

It is closed with plastic steel and is beautiful and easy to observe. All are made into a movable window, which is easy to enter when adjusting. The pump uses two units of 100 cubic meters per hour (one spare). The cooling water pipe regulating valve is installed on the side of the operation cabinet for easy adjustment.

Eight, air compressor and pipe mechanism:

Nine, secondary descaling machine:

X. Pipeline platform

XI. Inner epoxy powder coating equipment:

Twelve, manufacturing and installation schedule

The production period is 70 days from the effective date of the contract, and the installation period is 30 days (the installation conditions are available)

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved