Full bridge 10KW electromagnetic heater

Full bridge 10KW electromagnetic heater Full bridge 5 KW-8KW electromagnetic heater

Full bridge 5 KW-8KW electromagnetic heater Electromagnetic induction heater

Electromagnetic induction heater 60KW electromagnetic induction heater

60KW electromagnetic induction heater 50KW electromagnetic induction heater

50KW electromagnetic induction heater 40KW Electromagnetic Induction Heater

40KW Electromagnetic Induction Heater 20KW electromagnetic induction heater

20KW electromagnetic induction heater 15KW electromagnetic induction heater

15KW electromagnetic induction heater  10KW electromagnetic induction heater

10KW electromagnetic induction heater 5KW electromagnetic induction heater

5KW electromagnetic induction heater  3KW electromagnetic induction heater

3KW electromagnetic induction heater 2.5KW electromagnetic induction heater

2.5KW electromagnetic induction heaterFirst, product electrical specifications

1 , rated voltage frequency: AC 220V / 50Hz

2 , voltage adaptation range: 100V ~ 260V

3 , rated power: 3KW ( power adjustable range is 20 ~ 100%) , rated working current: 12 ~ 14A

Second, the environmental adaptability

1 , temperature: -20 °C ~ 50 °C

2 , humidity: ≤ 95%

Third, 3KW electromagnetic heater basic selection method

1 , voltage and power characteristics: 210 ~ 260V constant power output;

2 , thermal efficiency ≥ 95% ;

3 , IGBT overheat protection temperature: 85 ± 5 °C;

4 , working frequency: 5 ~ 40KHz ;

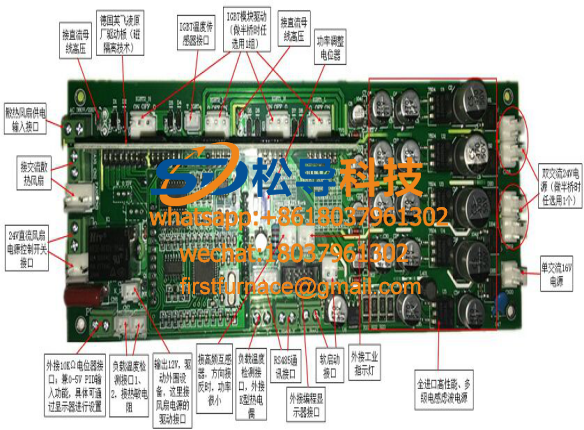

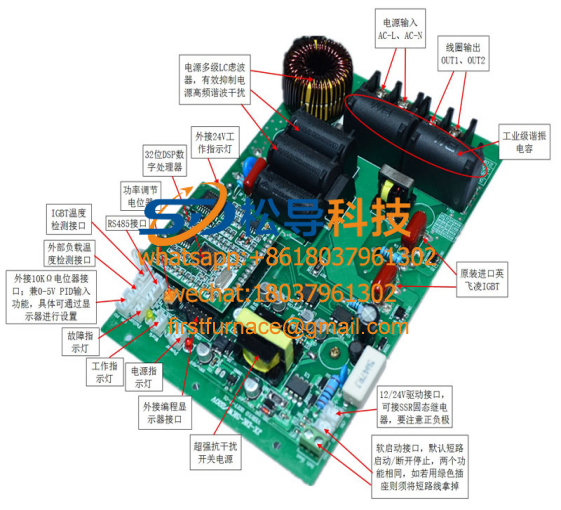

5 , based on 32 -bit DSP full digital processor, half-bridge series resonance;

6 , using digital phase-locked loop control technology, digital stepless adjustment, can set the power level through digital display, can also be adjusted by external potentiometer, and is also compatible with 0~5VDC or 4 ~ 20mA analog PID control power output, achieve power 20% to 100% adjustable;

7. It has an electrically isolated soft start control interface (short circuit start / stop stop) for easy connection with the thermostat; and 12V/24V input start / stop mode control interface for easy connection with various solid state relays (with voltage input) Work, otherwise stop heating, when using this function, the soft start interface is empty, and the shorting ring needs to be removed), the control response speed is fast, the starting time is < 1S ;

8 , with heating coil short circuit, open circuit and other protection functions, 130% overload and no-load transient protection function, protection response time ≤ 2uS ;

9. Wide coil compatibility, compatible with the same model of other companies;

10 , strong anti-interference ability, can control 30 controllers simultaneously start / stop at the same heating body without mutual interference;

11. Open application platform, users can automatically read the important parameters such as current, frequency, phase difference, temperature, etc. with our dedicated digital programming display. It can also set various application parameters according to the needs, making installation and debugging more simple and convenient;

12 , can set 1 ~ 255 days working time, automatically lock after timing, you need to enter the password to restart, in addition, you can also set 6 groups of scheduled on / off according to need ;

13 , built-in modbus RTU Communication protocol, with 485 interface, external touch screen, and easy remote control;

14 、Using industrial grade components, 100% high temperature aging test, ensuring continuous and reliable operation for 24 hours in industrial environment of 50 °C for a long time , average fault-free service life: ≥ 50000Hrs ;

15 、Factory standard configuration: control board, heat sink and cooling fan are integrated, equipped with chassis and digital programming display;

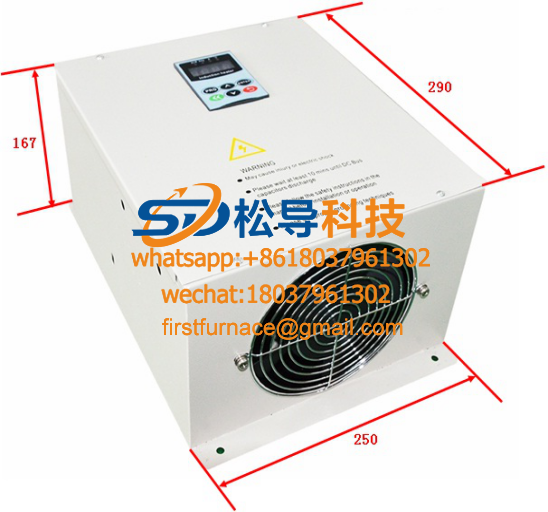

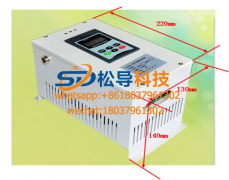

16 , physical size: length 220mm * width 130mm * height 140mm (including chassis);

Fourth, 3KW electromagnetic heater electromagnetic heating controller advantages

1. The power supply adopts wide voltage design and constant power output from 210V to 260V , which is especially suitable for occasions where the grid voltage fluctuation is large;

2 , using double 60A imported IGBT (G60N120D) half-bridge series resonant structure, product quality is more stable, anti-interference ability is stronger, long-term continuous work does not burn the board;

3. The power can be set by digital display, or it can be adjusted by external potentiometer. It is also compatible with 0~5VDC or 4~20mA analog PID control power output, which makes the heating temperature control more precise and more suitable for various heating equipment. Production support;

4 , can set the working time for password lock, effectively prevent the problem of difficult project collection; can also set up 6 groups of scheduled on / off according to needs , more intelligent, more convenient for the peak and valley electricity price area;

5 , comes with 485 interface, can be connected to the touch screen, can also easily achieve remote control and centralized control, is conducive to the secondary development of equipment and integrated management of the factory;

6. Add 12V/24V voltage control interface to facilitate the use of SSR solid state relay control;

7 , the national unified warranty for 1 year, product life-long maintenance, the entire process of technical guidance and services, so that you have no worries.

Coil 15 ~ 25mm , flat coil: 10 ~ 15mm , the working current of the quota: 12 ~ 14A , the general working frequency is: 10K ~ 20KHZ .

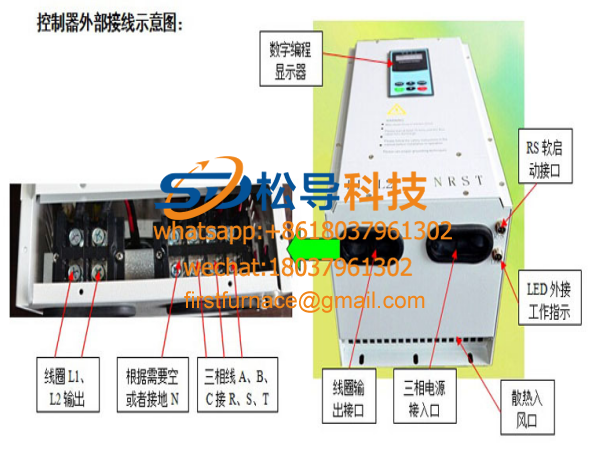

Five: 3KW electromagnetic heater control board wiring method

3KW electromagnetic heater controller installation dimension drawing:

Six, 3KW electromagnetic heater products range:

1. Rubber and plastics industry: various processing equipment such as injection molding machine, film blowing machine, extruder, granulator, blow molding machine, wire drawing machine, plastic dryer, rubber deoiling tank, etc.

2 , chemical industry: reaction kettle, vulcanizing machine, various wax processing, etc.

3 , food industry: tea machinery, roasted seeds and nuts machine, pancake machine, spring roll machine, bean machine, braised pork pot, etc.

4 , oilfield and other refining industry: oil pipeline heating and repair, lubricant refining, etc.

5. Medical, pharmaceutical and health industries: steam boilers, pharmaceutical heaters, medical equipment, etc.

6 , boilers: heat transfer oil boilers, hot water boilers, heating boilers, ironing boilers, etc.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved