Flywheel ring gear high frequency quenching equipment

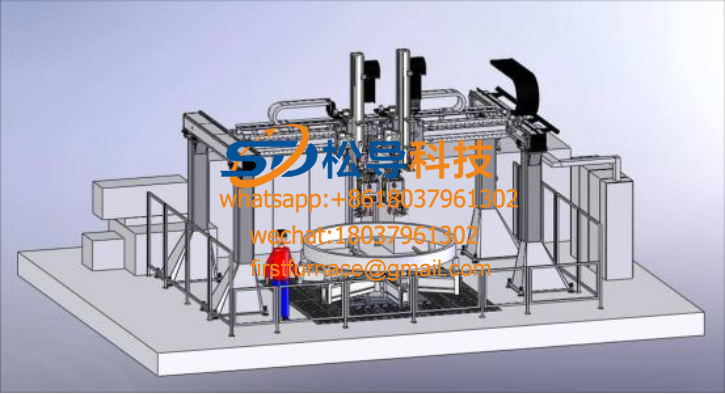

Flywheel ring gear high frequency quenching equipment Fully automatic gear high frequency quenching equipment

Fully automatic gear high frequency quenching equipment Vertical numerical control induction hardening equipment

Vertical numerical control induction hardening equipment Vertical high frequency quenching equipment

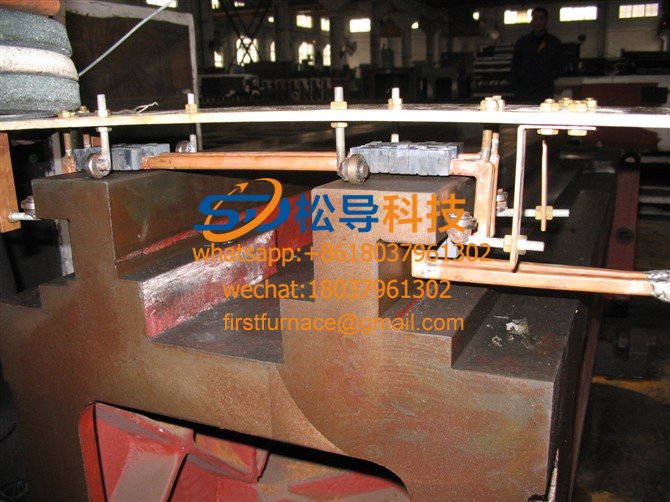

Vertical high frequency quenching equipment  Machine tool guide table surface quenching equipment

Machine tool guide table surface quenching equipment Machine tool guide quenching equipment

Machine tool guide quenching equipment Piston rod quenching special equipment

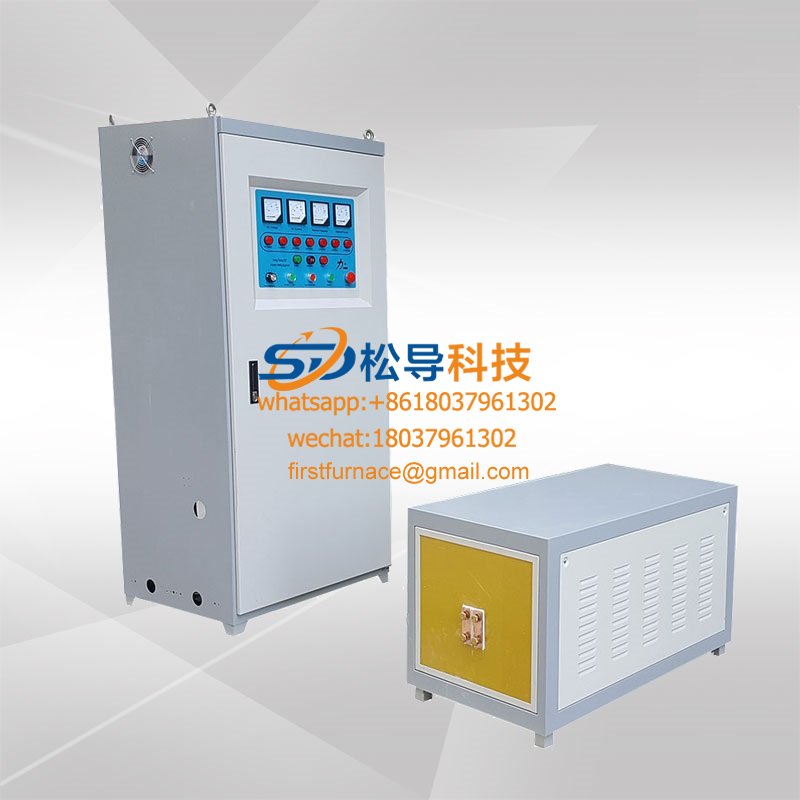

Piston rod quenching special equipment  High frequency quenching equipment

High frequency quenching equipment Induction hardening equipment

Induction hardening equipment Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment  Pump tube inner wall quenching equipment

Pump tube inner wall quenching equipment Milling machine guide quenching equipment

Milling machine guide quenching equipment Medium frequency induction hardening equipment

Medium frequency induction hardening equipment Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment Quenching equipment

Quenching equipment gear intermediate frequency quenching equipment

gear intermediate frequency quenching equipment lathe guide quenching equipment

lathe guide quenching equipment 400KW/4KHZ quenching equipment configuration options

400KW/4KHZ quenching equipment configuration options pump tube quenching equipment

pump tube quenching equipmentModel: SD-CHJ

Power: 15-160KW

Shaft type: φ10-300mm L: 50-1500mm

Gear type: φ20-300mm H: 10-600mm

Automatic gear quenching equipment application range: suitable for quenching and tempering of various workpieces, such as induction quenching of shafts, gears, discs and other parts.

Fully automatic gear high frequency quenching equipment application range

1 , It is suitable for quenching and tempering of various workpieces, such as induction quenching of shafts, gears, guide rails, discs, pins, and other parts;

2 , with continuous quenching, at the same time quenching, segmental continuous quenching, segmentation and quenching and other functions;

3 , using CNC system or PLC and variable frequency speed control system to achieve workpiece positioning, scanning, and through the PLC and induction power supply online, to achieve fully automated production.

4 , vertical (shaft parts quenching) + horizontal (ring ring parts quenching)

Selection of main technical parameters of automatic gear high frequency quenching equipment

power | 10KW-300KW (with multiple specifications of induction power supply for induction hardening) |

Quenching method | Continuous quenching, simultaneous quenching, segmental continuous quenching, segmentation and simultaneous quenching |

Quenching length | 2500mm |

Quenching diameter | 1200mm |

Quenching weight | 500kg |

X- axis travel | 200mm |

Y- axis travel | 300mm |

Z- axis travel | 1500mm |

Fully automatic gear high frequency quenching equipment performance characteristics

1 , CNC system, can prepare and store a variety of quenching process procedures according to different workpiece requirements;

2 , With energy saving, environmental protection, intelligent, automatic, less oxidation, less deformation and so on;

3 , The control precision and the degree of automation are high, the consistency of the workpiece quality after heat treatment is good, and the quench hardened layer is consistent;

4, no manual adjustment during quenching, quenching equipment automatically, high heating efficiency, low labor intensity;

5 , It has the functions of continuous quenching, simultaneous quenching, segmental continuous quenching, and simultaneous quenching;

6, using the workpiece moves, can realize continuous scan quenching parts quenching, quenching scan segment, the segment through the entire work hardening;

7 , Stepless adjustable: quenching speed, working speed;

Workpiece display

|

|

|

Fully automatic gear quenching equipment is quenching | Automatic gear quenching equipment induction heater | After quenching |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved