5T parallel intermediate frequency furnace

5T parallel intermediate frequency furnace 1T parallel intermediate frequency furnace

1T parallel intermediate frequency furnace 2T Parallel Intermediate Frequency Furnace

2T Parallel Intermediate Frequency Furnace  0.5T parallel intermediate frequency furnace

0.5T parallel intermediate frequency furnace 0.25T parallel intermediate frequency furnace

0.25T parallel intermediate frequency furnace Parallel intermediate frequency furnace

Parallel intermediate frequency furnace 3T parallel intermediate frequency furnace

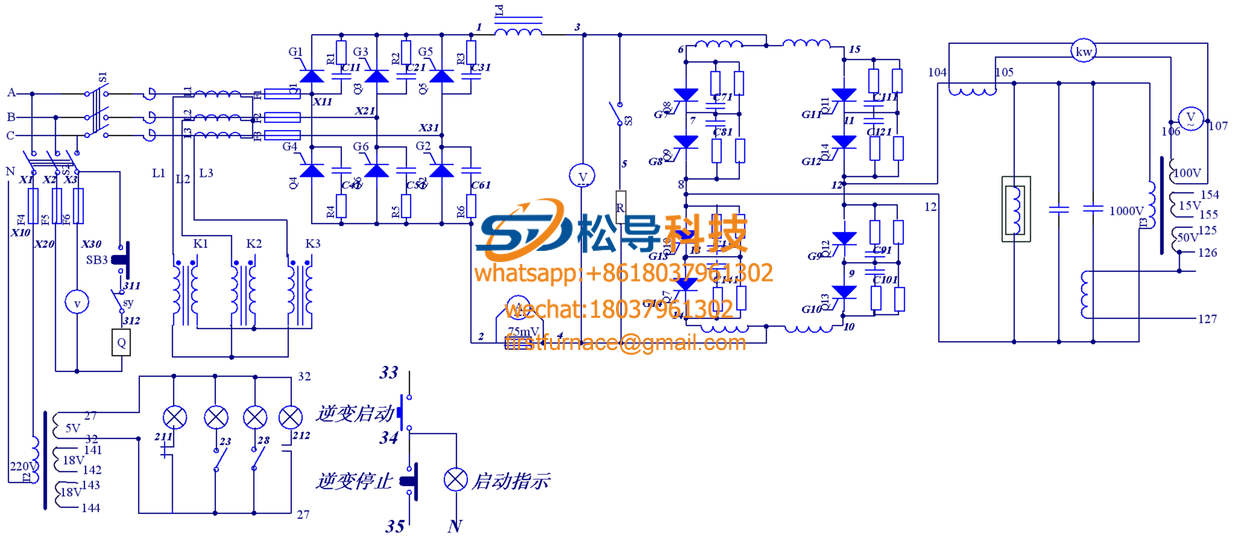

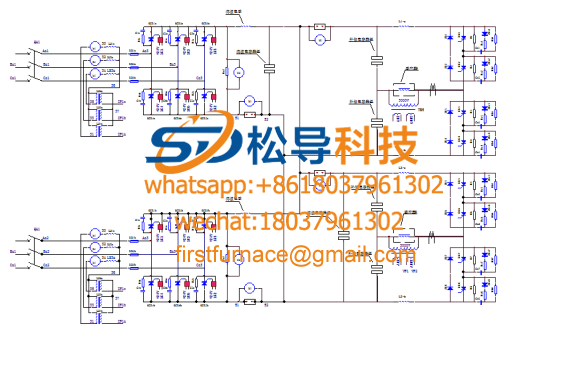

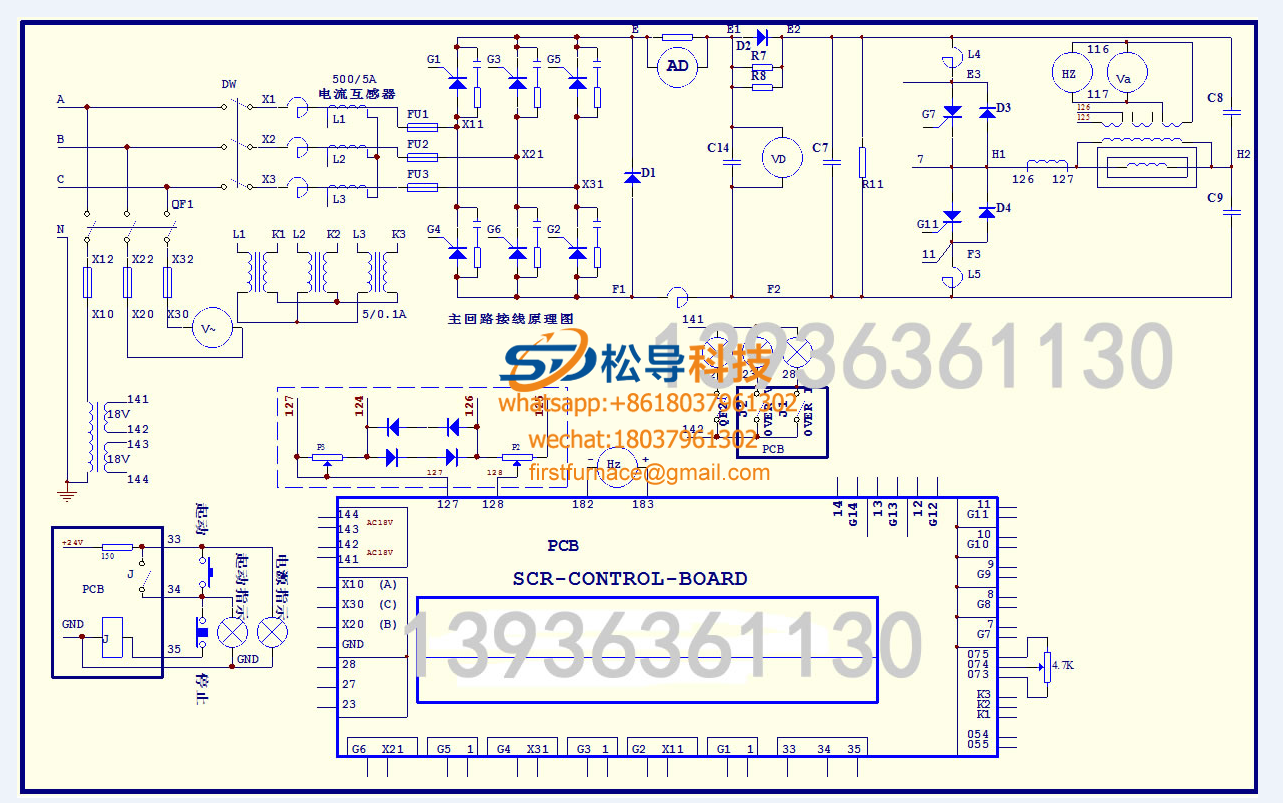

3T parallel intermediate frequency furnace Intermediate frequency furnace main circuit schematic

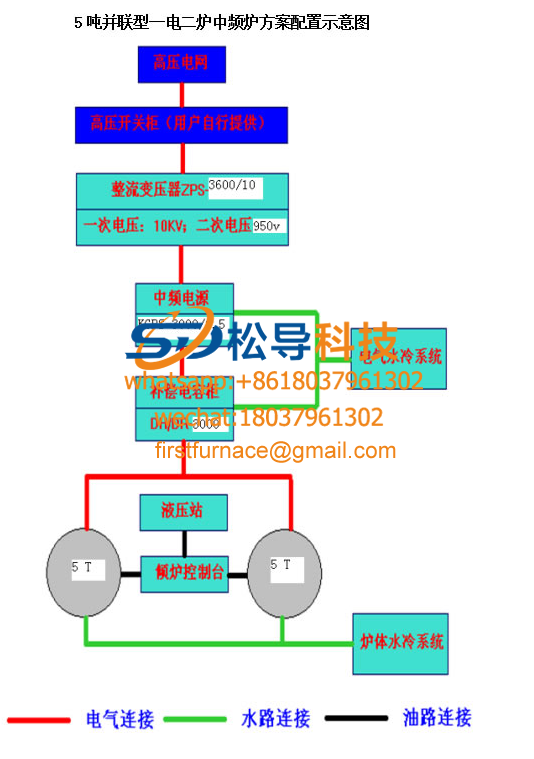

Intermediate frequency furnace main circuit schematic Schematic diagram of 5 tons of intermediate frequency melting

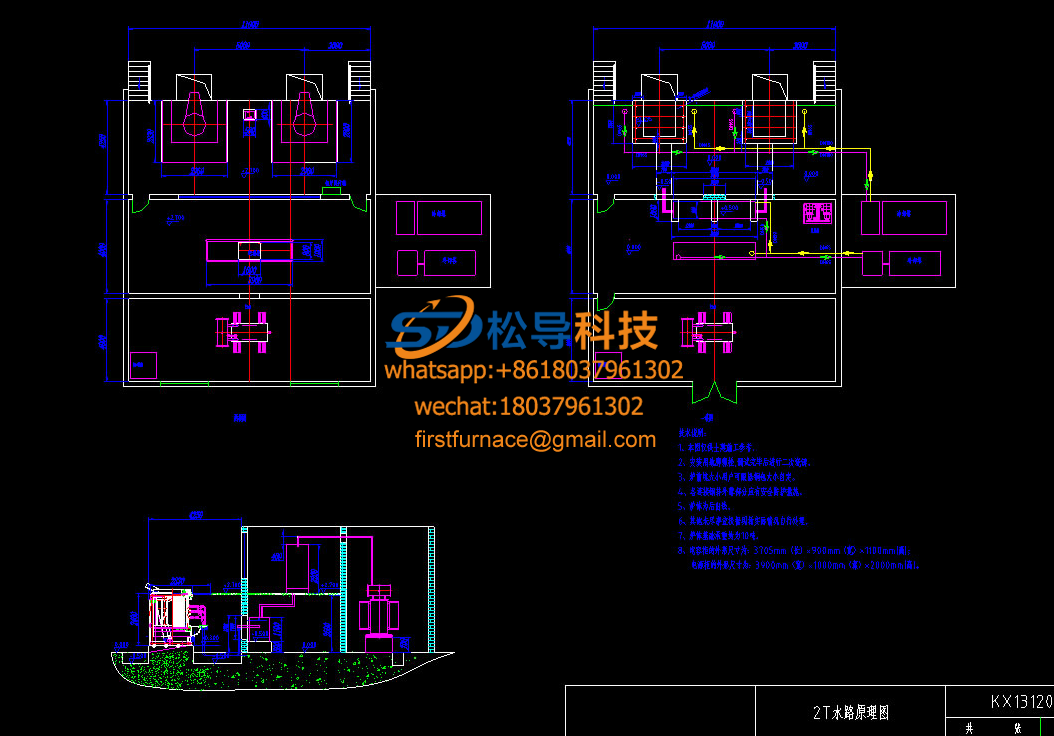

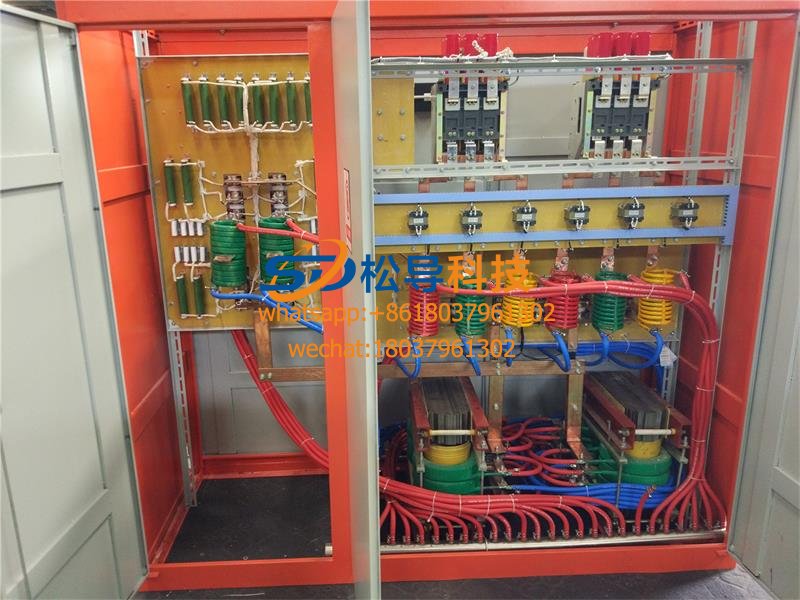

Schematic diagram of 5 tons of intermediate frequency melting 2 tons intermediate frequency furnace floor plan

2 tons intermediate frequency furnace floor plan Technical Drawing of Simple Layout of Intermediate Frequency

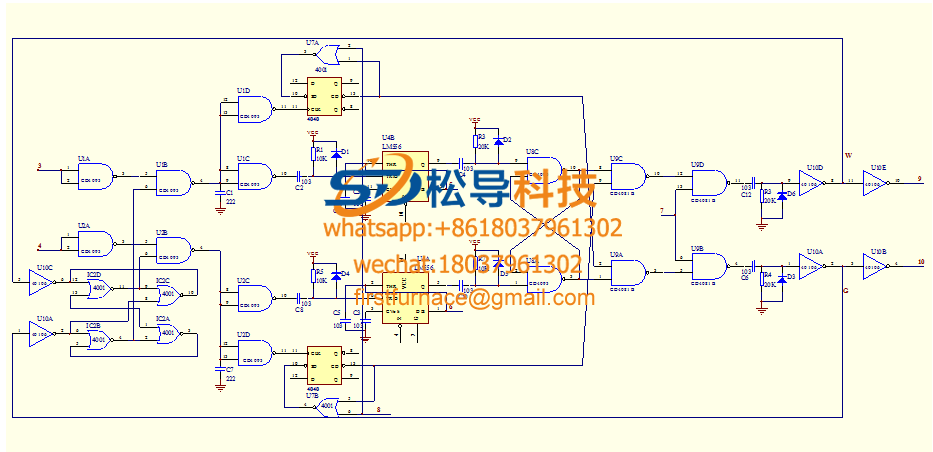

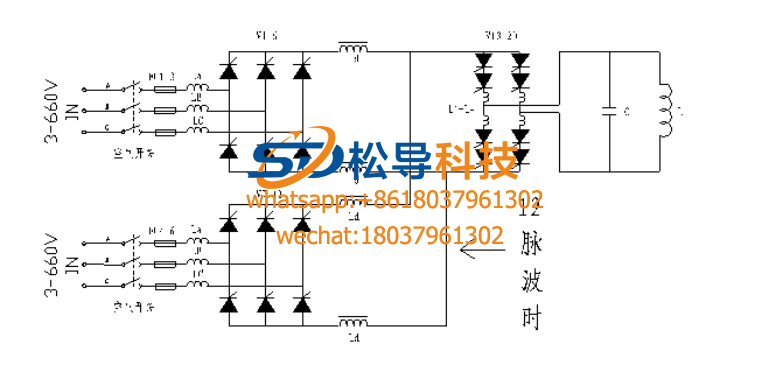

Technical Drawing of Simple Layout of Intermediate Frequency  Series intermediate frequency furnace triggering electrical s

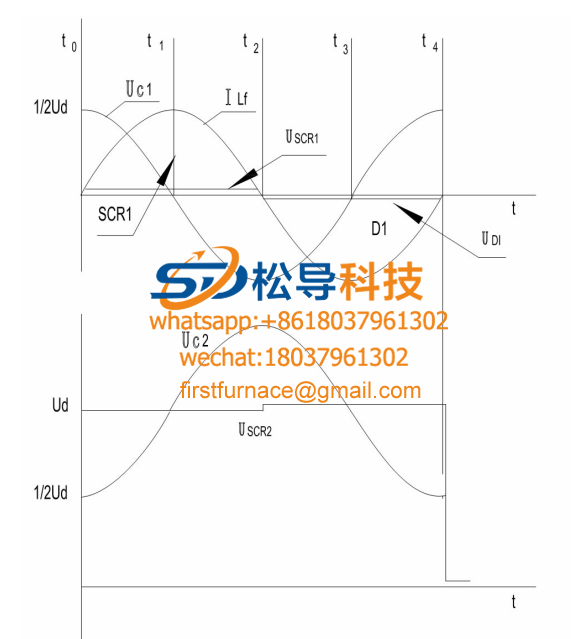

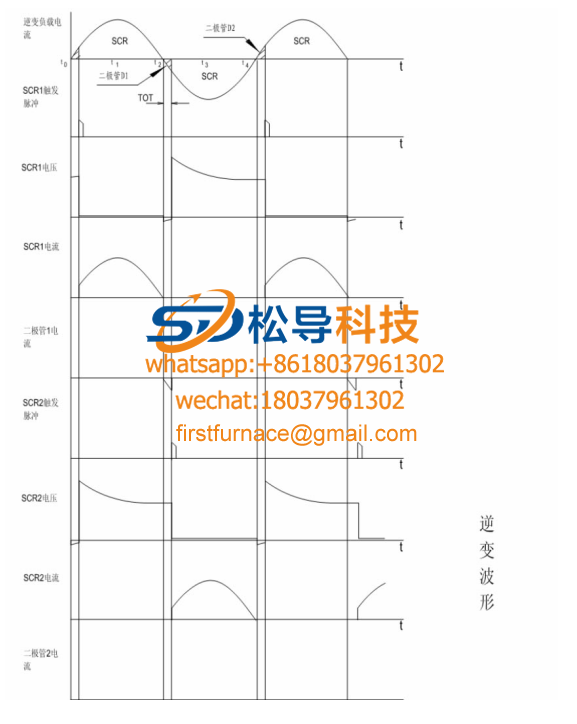

Series intermediate frequency furnace triggering electrical s Series intermediate frequency furnace inverter electrical wav

Series intermediate frequency furnace inverter electrical wav Series intermediate frequency furnace inverter circuit wavefo

Series intermediate frequency furnace inverter circuit wavefo 1T one belt two intermediate frequency furnace electrical sch

1T one belt two intermediate frequency furnace electrical sch 1 ton series intermediate frequency furnace main circuit draw

1 ton series intermediate frequency furnace main circuit draw 2T one belt two intermediate frequency furnace installation l

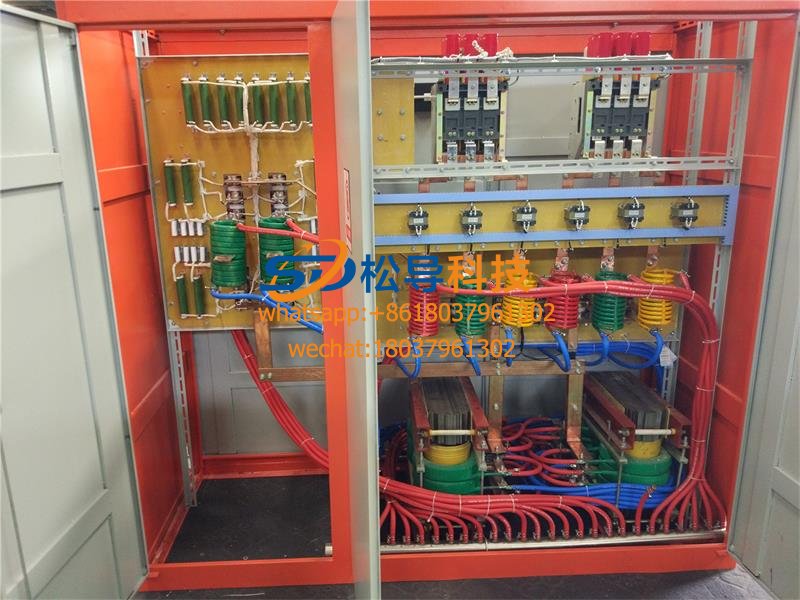

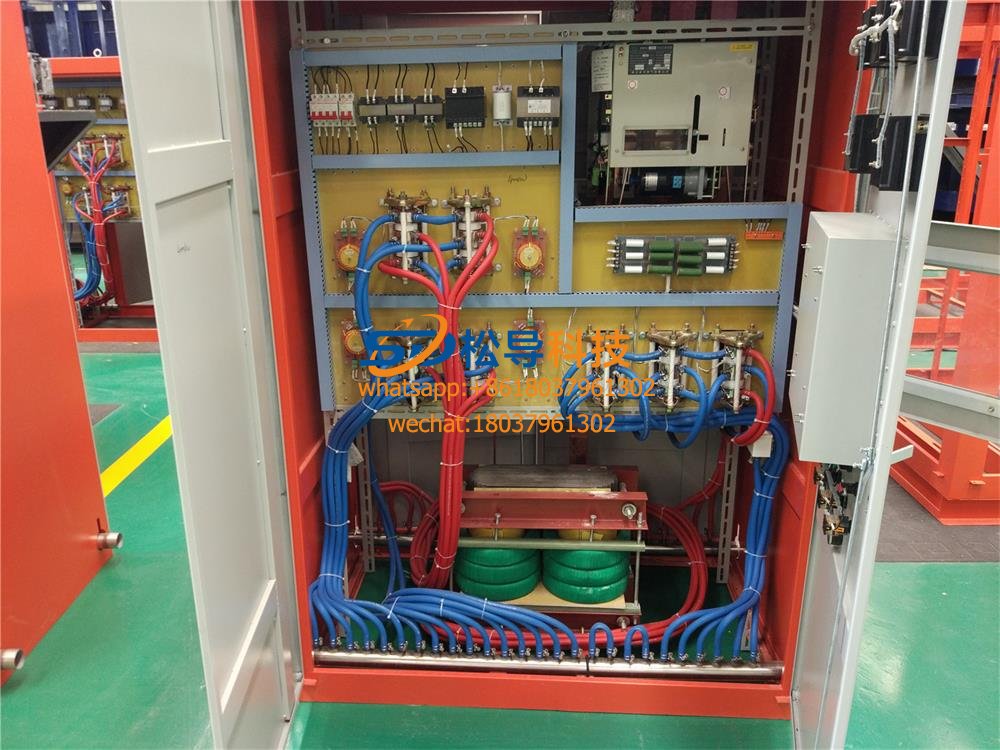

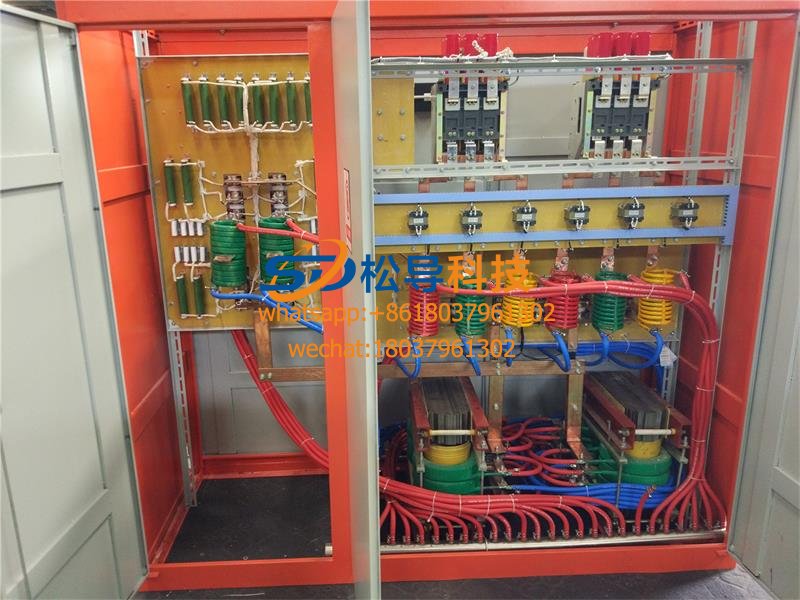

2T one belt two intermediate frequency furnace installation lThe components of the parallel intermediate frequency furnace :

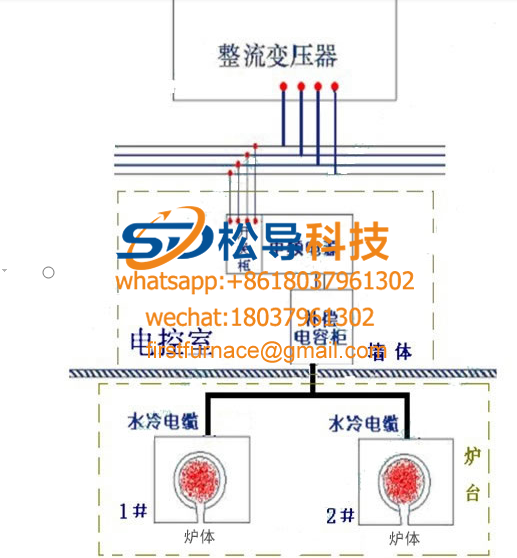

Parallel intermediate frequency furnace mainly includes intermediate frequency power supply, parallel inverter, aluminum shell furnace body or steel shell furnace body (the furnace body can be matched with selection)

The reason for choosing a parallel intermediate frequency furnace :

In the design of the parallel intermediate frequency furnace, the control circuit requires only two transformers and one control circuit board in addition to the conventional main circuit. The contactor, intermediate relay, and other auxiliary circuits are completely removed, so that the whole set of equipment is rarely connected. Moreover, since the three-phase AC input does not have to distinguish the phase sequence, the intermediate frequency output line does not have to distinguish the phase, which makes the user's on-site debugging more convenient. .

1, constant power control system digital (highly integrated control circuit),

2, constant power thyristor frequency power supply system is the company developed the intelligent controller. Mainly composed of regulator, phase shift controller, protection circuit, start-up calculation circuit, frequency tracking, inverter pulse formation, pulse amplification and power drive. After being digitized, it becomes a special chip, which is specially applied to the control of thyristor parallel inverter intermediate frequency power supply.

3 , Inverter control reference to the United States ABB , Ajax , Japan Fuji Electric and other foreign advanced control technology, self-developed inverter control technology, has a strong anti-interference ability.

4, the control panel for the digital integration panel board, digital trigger, high reliability, high precision, easy to debug without relay element, etc., no long-term temperature drift, the operating point stabilization.

5 , with perfect multi-level protection (water pressure, phase loss, under voltage, over current, over voltage, off time, straight through, operation interlock, etc.)

The startup mode is advanced sweep type, which stimulates the zero-voltage start, enabling the operator to achieve 100% successful start without selecting the start voltage and start frequency .

6. It can adjust the matching according to the change of load, and improve the melting and heating speed to save energy ( 10% ).

7. It has the following instrument indications: output voltage meter, output power meter, working frequency meter, medium frequency current meter, power factor meter, input voltage meter, earth leakage meter and fault warning indication. ( Electrical meter is installed between transformer and intermediate frequency power cabinet

8 , power start performance: reliability start-up (whether empty, full load). The power supply adopts a zero-voltage automatic sweeping start mode and has a frequent start function. The startup success rate is guaranteed to be 100% both under heavy load and no load .

9, when the heavy load is reduced commutation angle relative increase in voltage, reducing the current, power supply close to optimum (nominal) light load, increasing the commutation angle relative reduction ,, voltage, increasing the current, the power supply Working close to the best value (rated value)

10 , using parallel compensation circuit to reduce the loss of the transmission line In order to reduce the loss on the intermediate frequency transmission line, the compensation capacitor of the inverter is connected in series double voltage form. This connection allows the voltage on the electric furnace to be doubled compared to the inverter output voltage. In this way, the output current becomes 50 % of the original at the same output power , so that the loss on the intermediate frequency transmission line is reduced by 1/4 .

The advantages of parallel intermediate frequency furnace:

1. Due to the characteristics of the parallel resonant circuit, the variable frequency power supply with parallel resonance has good protection when the circuit is short-circuited. Because the reactor device with buffer function installed in the intermediate circuit can effectively suppress the rapid rise of current, it can be reliably turned off when the circuit fails.

2 , parallel resonant frequency conversion environmental source also has very low loss on the inverter side (because the large current only works in the resonant circuit) and precise coil voltage control (to make full use of the highest power of the capacitor group)

3 , the technology is mature, the performance of the whole machine is stable and reliable, and has a competitive advantage.

4, the operation is simple, easy to use

5 , the maintenance speed is fast, the maintenance difficulty and maintenance costs are low!

6 , the price is relatively cheap.

Parallel intermediate frequency furnace price

model | Rated Capacity | rated power | Price price ¥ (yuan) |

T | KW | One electric furnace | |

SDBL -250 kw | 0.25 | 250 | Total: ¥ 70500 Yuan |

SDBL -400 kw | 0.5 | 400 | Total: ¥ 148800 Yuan |

SDBL -500 kw | 0.75 | 500 | Total: ¥ 168800 Yuan |

SDBL -700 kw | 1 | 700 | Total: ¥ 221000 Yuan |

SDBL -1000 kw | 1.5 | 1000 | Total: ¥ 230000 Yuan |

SDBL -1500 kw | 2 | 1500 | Total: ¥ 361500 Yuan |

SDBL -2000 kw | 3 | 2000 | Total: ¥ 447000 Yuan |

SDBL -3000 kw | 5 | 3000 | Total: ¥ 643000 Yuan |

SDBL -4000 kw | 6 | 4000 | Total: ¥ 7 43000 Yuan |

SDBL -4500 kw | 8 | 4500 | Total: ¥ 8 43000 Yuan |

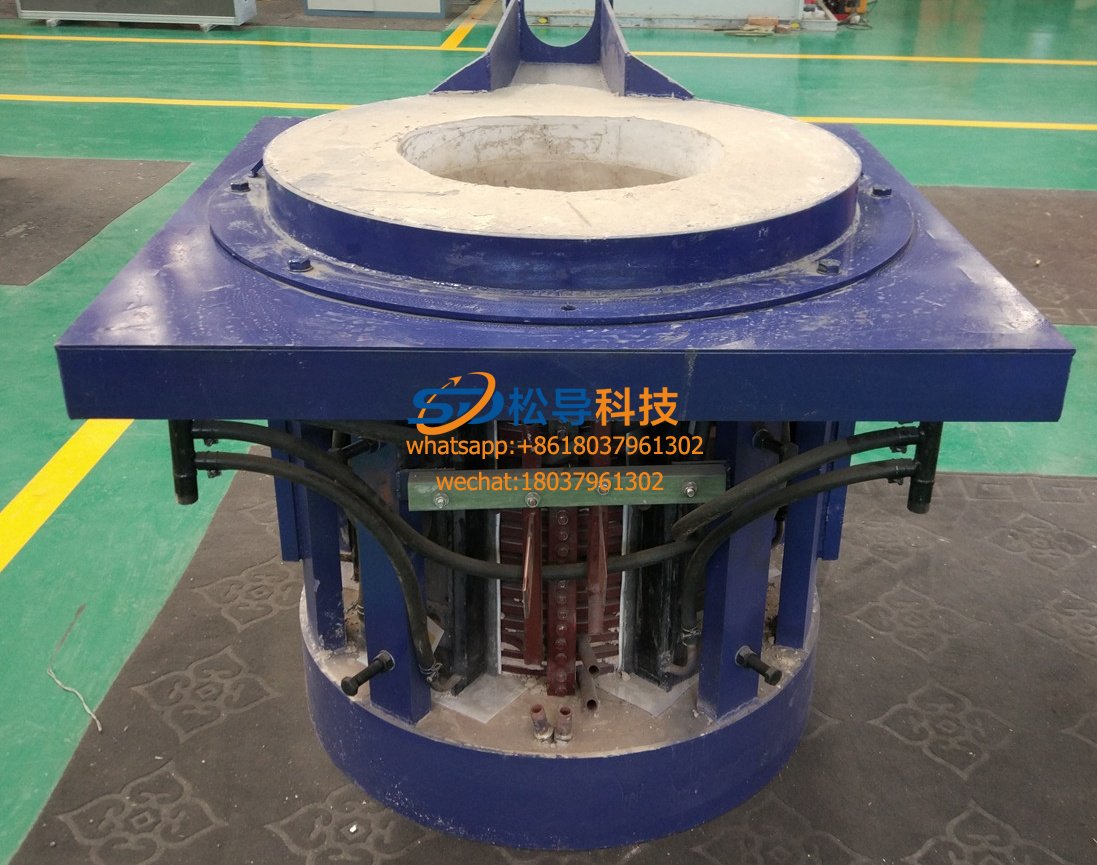

Parallel medium frequency furnace steel shell furnace body selection method

Open furnace body , hob, tilting cylinder, inductor, yoke, high pressure carbonless hose, furnace and bottom casting, complete stainless steel water distributor, return water collector and clamp, etc. The wall is loaded with water and water.

uOpen steel frame structure, easy to maintain, overhaul, large-size H- shaped steel or square steel tube constitutes the basic structure of the hob, the overall structure is simple and sturdy, and the maximum furnace inclination angle is 95 degrees.

u Welded steel structure with appropriate support and clamping parts to fix the induction furnace coil and yoke; the upper part of the induction furnace is detachable, which makes it easier to replace the coil.

The heavy-duty steel members on both sides of the truss become the strongest support of the furnace body, providing the axis of hydraulic tilting, and the shaft center moves outward and moves up. Ensure that the taphole has the smallest trajectory and reduce the energy loss of tapping.

The copper tube of the induction coil is assembled with a solid, durable and highly conductive TU1 oxygen-free copper tube with a purity of 99.9 % and a wall thickness of ≥ 5 mm . The coil is supplied with cooling water from multiple water channels and evenly distributed. Shot blasting and purging, then enter the drying room for baking, sprayed with insulating ceramic paint or tightly wrapped with insulating material. Class H insulation level required to achieve. The induction coils are 10kg / cm2 pressure test pressure 12 hours. The upper end and the lower end of the induction coil are respectively equipped with a shield ring and a short-circuit ring to fully absorb the leakage flux at the upper and lower ends to prevent the furnace body from heating. The induction coil is energized and the water-cooled cable is in the form of a side lead.

The yoke yoke is evenly stressed by the buck bolt and provides maximum compression to the coil to ensure a long working life of the lining. The yoke is made of high-quality cold-rolled silicon steel sheet. The tolerance of the shearing edge of the silicon steel sheet after processing is <0.1mm . The bending degree after assembly meets the requirements of TB/T4280-93 to ensure the arc-shaped contact between the coil and the yoke. , precision fit. At the same time, multiple sets of yoke fastening devices are firm and reliable, easy to assemble, disassemble, adjust and repair, and evenly distributed along the circumference (error ≦ 0.5) , covering the coil area of more than 55% ; the lining and the coil between the coils are multi-layer high Insulating material of quality, including multi-layer mica plate, multi-layer ceramic fiber board, yoke is water-cooled.

Parallel intermediate frequency furnace circuit diagram :

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved