First, lead melting furnace introduction:

Titanium pot, heating plate, intelligent temperature °C control board:

Titanium pot: Titanium pot is made of Japan's AT1 pure titanium foot 2MM thick titanium plate, hard °C is 65 ° C of superior titanium, more resistant to strong acid and salty corrosion.

Heating plate: The heating wire inside the heating plate is 300 yuan 1 kilogram of nickel wire, and the high temperature °C surface will not oxidize, the heating wire is afraid of oxidation.

Second, the intelligent temperature °C control panel:

The intelligent temperature control board used is the self-developed self-owned brand intelligent temperature control board with PID self-tuning function. The components and ICs all adopt imported brand products, the precision °C is 0.2 °C, the temperature of the tin in the tin pot is °C and the setting is The temperature °C error is about 2 °C. Our intelligent temperature control board has an over-temperature alarm prompt. As long as the temperature °C in the tin pot exceeds the set temperature °C of 50 °C, the red indicator light will be bright.

Adoption and understanding of each component:

1. Switch: It adopts the positive button type control switch, which is simple and simple to operate, and has a longer service life than other miscellaneous switches;

2, insulation cotton: the use of 20mm ultra-thick high-quality aluminum silicate insulation cotton, good insulation performance (non-inferior asbestos). Surrounded by

They are covered with this kind of insulation cotton, and the insulation performance is good, which not only can avoid frequent heating of the heating core, but also save energy and save the service life;

3, the heating plate: the use of high-quality ceramic strips, the hole position concentric °C high, the heating area is more uniform, nickel-chromium heating wire, heat efficiency and longevity;

4, casing: the use of insulated high temperature casing, protect the heating core leads, can avoid the aging of the ceramic beads in the lead part

A safety incident that causes leakage.

Third, the use of lead melting furnace

1. When working on the molten tin furnace, be sure to put it on a stable, heat-resistant workbench. Be careful to prevent hot tin from splashing from the tin pot.

2, can not empty the tin pot, this will lead to tin oxidation too fast; can add small pieces of tin or a small part of the molten tin, which

It can guarantee timely heat transfer.

3. It is forbidden to use a melting furnace near flammable gases and inflammable and explosive materials. When moving the tin melting furnace, be sure to turn off the power first, and then wait until the tin furnace is cooled to room temperature.

4. This product is a high-temperature equipment. When not in use, be sure to cut off the power supply to avoid accidents. The safety and service life of the tin furnace, the continuous working time of the tin furnace can not exceed 12 hours; in addition, for personal safety and the tin furnace can work normally,

Be sure to remember not to burn the tin furnace empty. Use it with a grounded power supply. Note that the ground wire cannot be connected to the neutral line.

5. The lead-free tin melting furnace adopts a lead-free environmentally-friendly titanium tin pot. After a high temperature burning for a period of time, the surface of the pot body will become golden or blue, which is one of the characteristics of titanium.

6. If the customer cooks strong corrosive materials such as acid, alkali and tin slag during use, the tin pot and the heating element are not guaranteed. This tin furnace is not waterproof and should be protected from moisture during use.

Failure analysis and maintenance:

1. Turn on the power, check if the fuse is open, or if the socket is plugged in.

2. After the start-up, the temperature °C display does not change, and does not heat up, indicating that the heating element is disconnected.

3. If the left display temperature °C is high after power on, the right side displays HIA or ORA and keeps flashing, indicating that the thermocouple is open or the temperature control board is faulty.

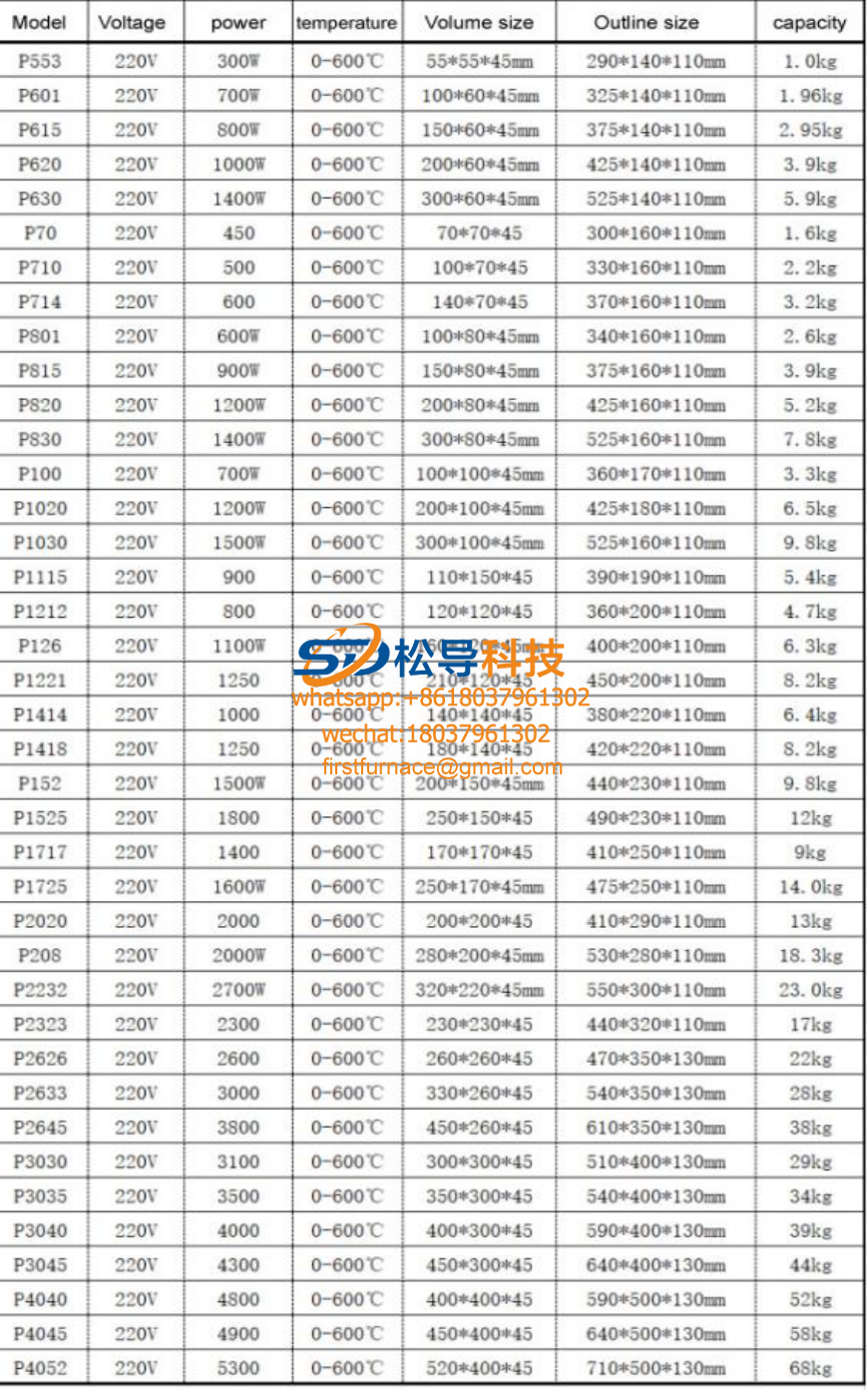

Fourth, lead melting furnace technical parameters summary

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved