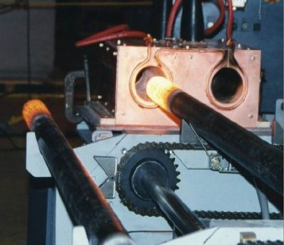

Tubing end induction heating equipment

Tubing end induction heating equipment steel pipe induction heating equipment

steel pipe induction heating equipment Steel tube induction heating furnace

Steel tube induction heating furnace Steel pipe medium frequency heating furnace

Steel pipe medium frequency heating furnace steel pipe heating equipment

steel pipe heating equipment Steel pipe induction heating equipment

Steel pipe induction heating equipment Drill rod end intermediate frequency heating equipment

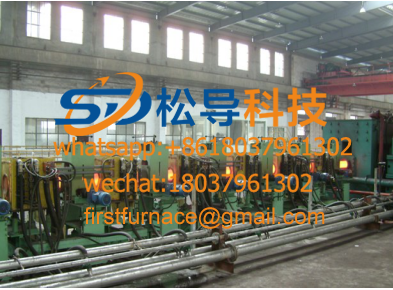

Drill rod end intermediate frequency heating equipment Steel pipe online heating equipment

Steel pipe online heating equipment Steel pipe electric heating equipment

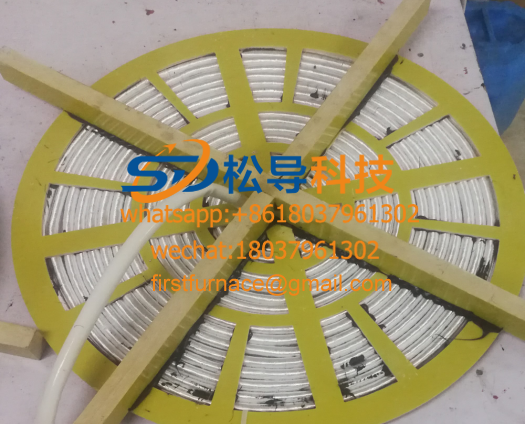

Steel pipe electric heating equipment Flat panel induction heater

Flat panel induction heater Induction heating belt

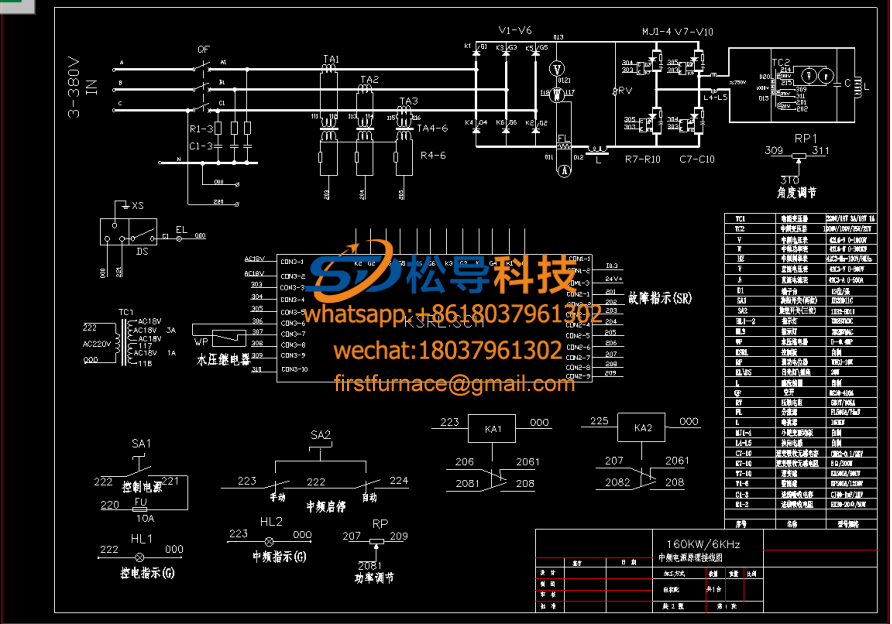

Induction heating belt 160kw medium frequency induction heating furnace electrical s

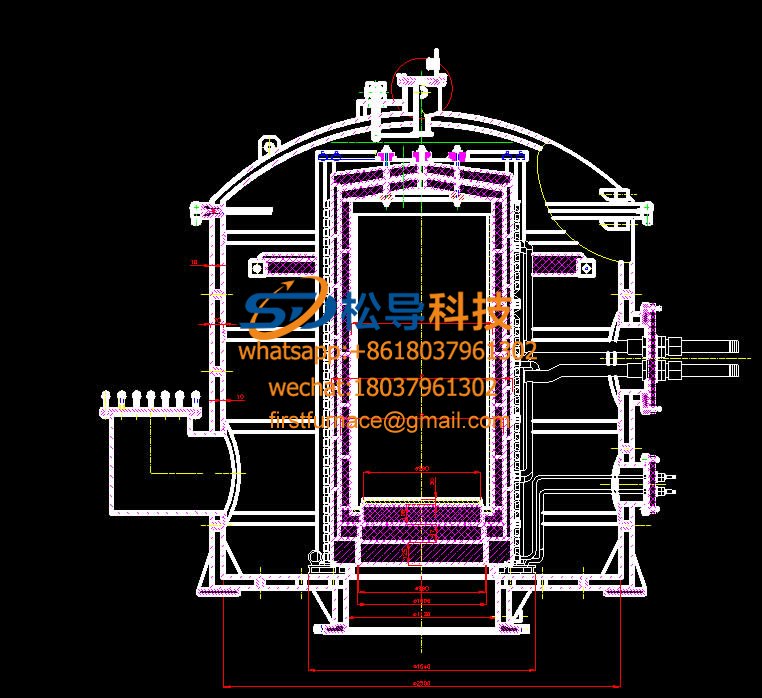

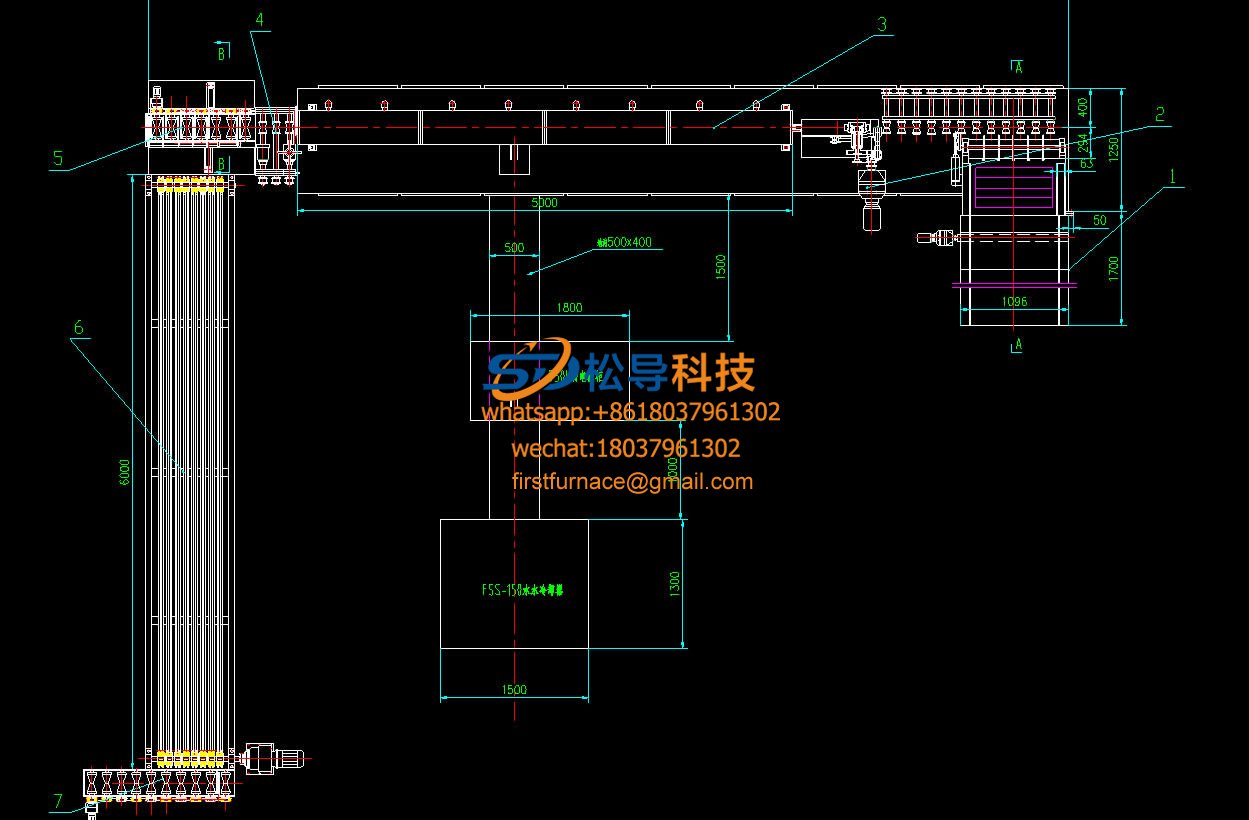

160kw medium frequency induction heating furnace electrical s Schematic diagram of plane layout of 1 ton medium frequency i

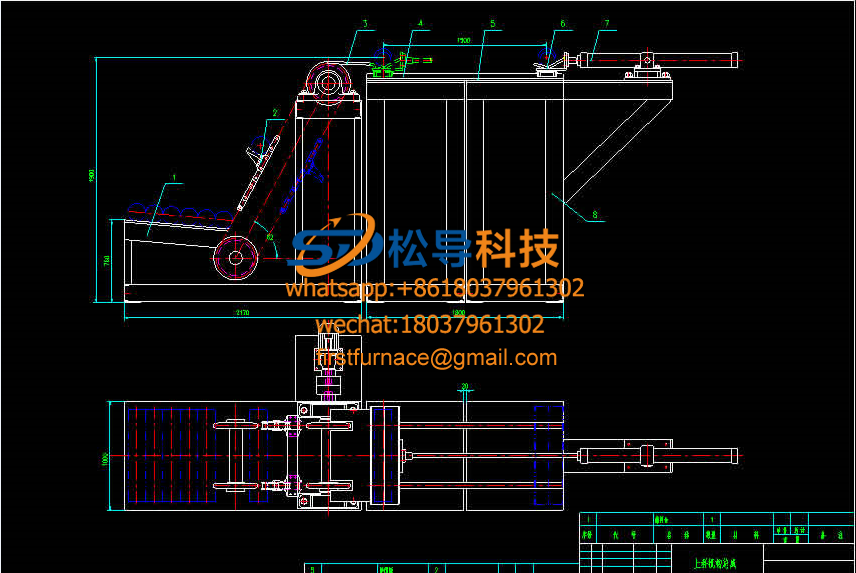

Schematic diagram of plane layout of 1 ton medium frequency i Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

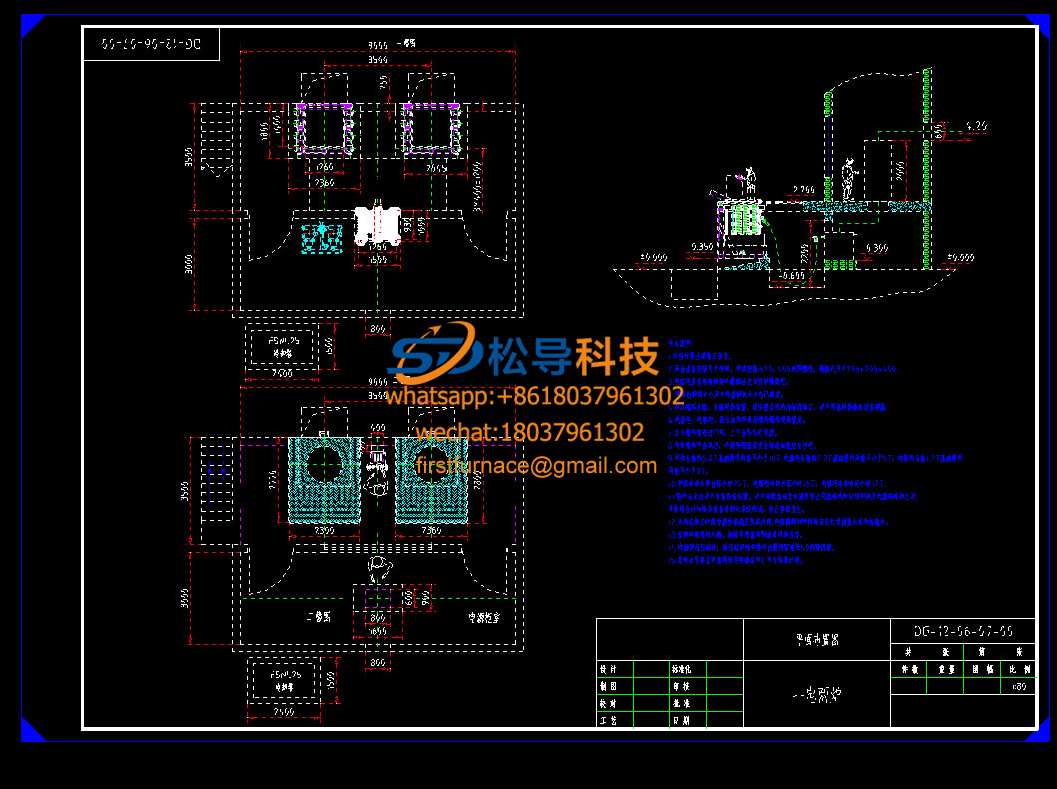

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

Bar Induction Heating Furnace Foundation Map On-site Use of Drill Pipe Heat Treatment Equipment

On-site Use of Drill Pipe Heat Treatment Equipment Molybdenum wire molybdenum block sintering furnace structure

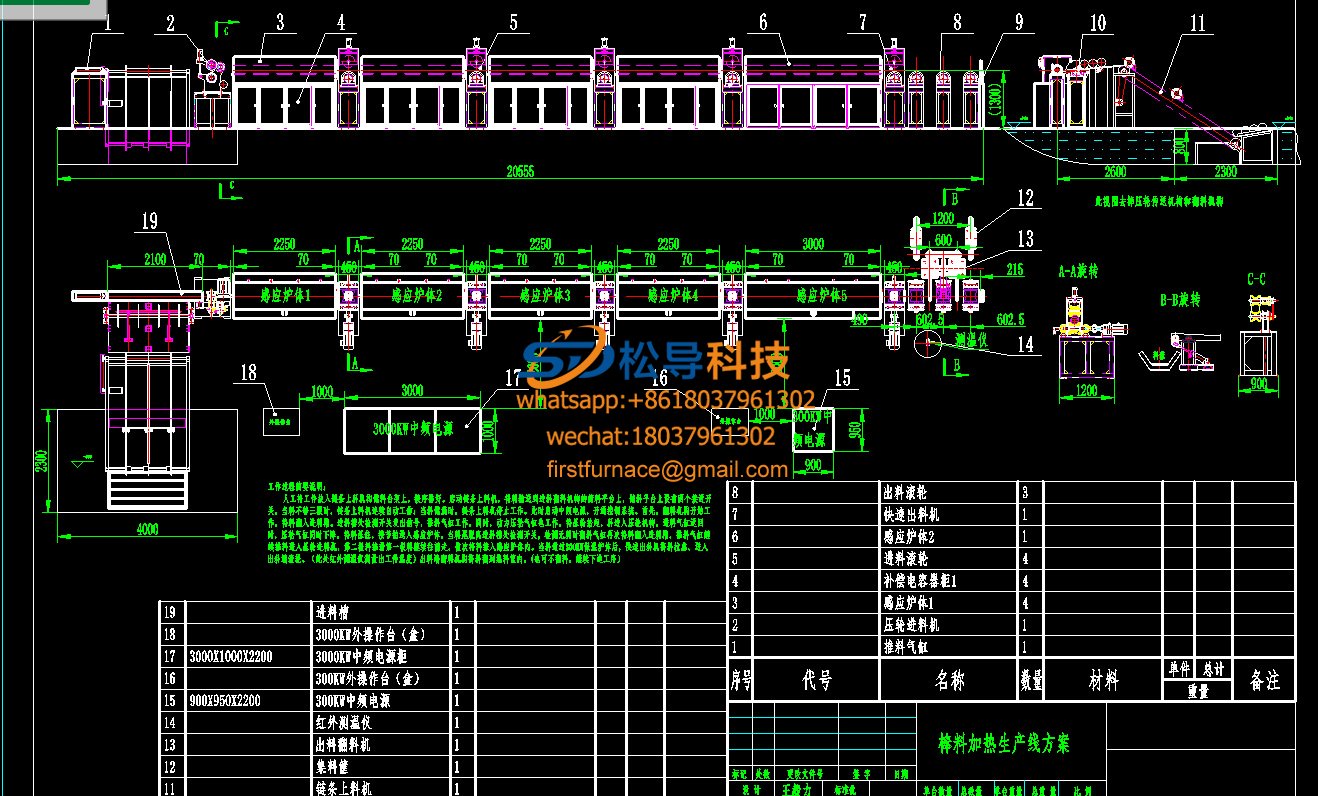

Molybdenum wire molybdenum block sintering furnace structure  Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating FurnThe steel tube induction heating equipment is fully automatic and intelligent, and the heating temperature is uniform. Infrared temperature measurement closed-loop control system for precise temperature control. The industrial computer system realizes automatic storage and storage of working parameters. Improve the production efficiency and product quality of steel tube induction heating equipment.

Summary of parameters of steel pipe induction heating equipment :

diameter | length | temperature | Control System | Power supply |

Φ 16mm | 300mm | 950 o C | PLC intelligent control system | KGPS 250KW |

Φ 30-70mm | 100-500mm | 1250 o C | PLC intelligent control system | KGPS 600KW |

Φ 80-110mm | 1500mm | 1250 o C | PLC intelligent control system | KGPS 2000KW |

Φ 16-32mm | 300mm | 1250 o C | PLC intelligent control system | KGPS 300KW |

Customized production of steel pipe induction heating equipment according to customers' actual needs | ||||

Steel pipe induction heating equipment PLC intelligent control system :

1, the user needs to provide a touch screen or a remote control console

2 , man-machine interface, easy to operate

3 , real-time adjustment of equipment operating parameters

4 , real-time control of the heating process, and has a recording function

5 , different international language switching

Induction heating equipment for steel pipes uses induction heating power control features:

1. Parallel resonance design, phase shifting and power adjustment, steel tube medium frequency heating furnace is mature and stable; it has more advantages in the high power range above 3000KW .

2 , DSP control, speed capture phase lock start, meet frequent start and stop, high success rate.

3 , Variable frequency variable load adaptation, frequency adaptation range 200-10000Hz, induction furnace replacement automatic matching, no manual adjustment is required.

4 , the cabinet uses T2 copper copper row, sandblasted, passivated treatment; low leakage, anti-oxidation, effectively reduce line loss.

5 , full touch screen control, pure digital setting, complete process record and strict hierarchical authority. The main parameters can be restored to the factory settings with one key.

6 , power single machine power 50-6000KW , frequency 200-10000Hz.

Features of steel pipe induction heating equipment :

1. Complete protection circuit, steel tube induction heating equipment has high reliability.

2 , steel pipe medium frequency heating furnace heating speed, less oxidative decarbonization, high success rate.

3 , variable frequency adaptive ability, fault self-diagnosis, intelligent protection system, steel tube intermediate frequency heating furnace has good resistance to voltage fluctuation, high power control precision and high starting rate.

4 , steel pipe medium frequency heating furnace using PLC man-machine interface combined control program, advanced technology, all digital, high depth adjustable parameters, heating evenly.

5. After the processed workpiece, there is no over-burning, no crack, high yield, tensile strength and straightness of the workpiece can satisfy the customer's requirements.

6. The medium-frequency induction equipment of steel pipe is controlled by two-color American Raytheon infrared thermometer. (The temperature can also be selected according to the user's choice of different types of thermometers.) The temperature is displayed in real time, the heating is more uniform, and the qualified rate of finished products is quite high.

Service process of steel pipe induction heating equipment:

1. The first-line service engineer and the second-line service technology expert have double technical support, and are always ready to solve the problems encountered by the equipment during the use of the equipment.

2 , to provide customers with technical workers, steel pipe induction heating equipment management and maintenance technology workers double free training services to meet customer satisfaction requirements.

3 , received customer demand, arrive at the scene at the latest on time, at the latest, to solve problems for customers.

4. In the latest 48 hours, deal with the problem of inductive heating equipment failure.

5 , according to the customer's personalized needs, provide more services related to electromagnetic induction heating equipment .

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved