Medium frequency quenching furnace

Medium frequency quenching furnace Shaft quenching machine

Shaft quenching machine Camshaft quenching machine

Camshaft quenching machine CNC quenching machine

CNC quenching machine ball head pin high frequency induction quenching furnace

ball head pin high frequency induction quenching furnace vertical shaft type high frequency quenching machine

vertical shaft type high frequency quenching machine vertical CNC induction hardening machine

vertical CNC induction hardening machine Piston rod quenching furnace

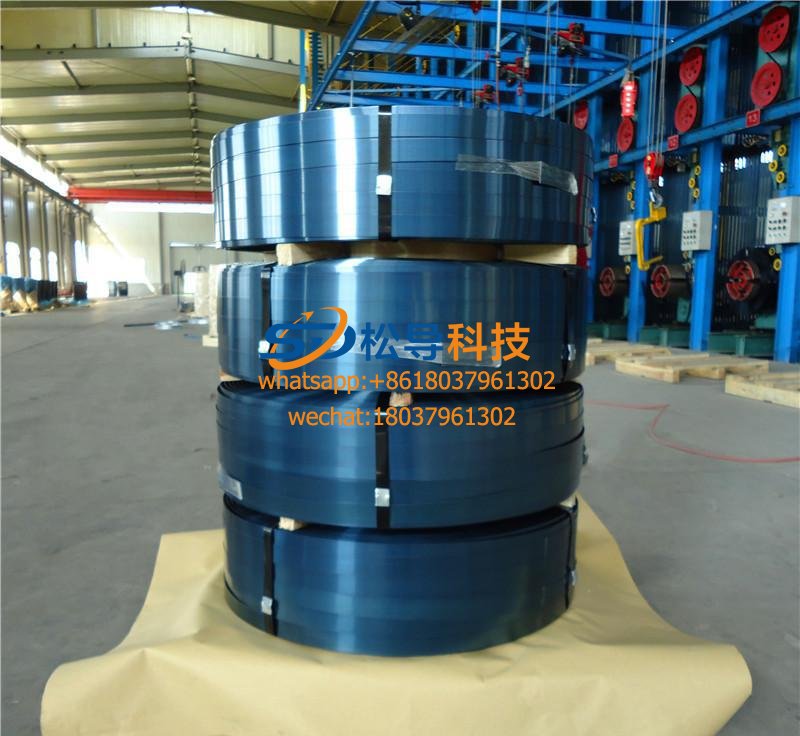

Piston rod quenching furnace Steel belt heating to blue induction heating equipment

Steel belt heating to blue induction heating equipment induction hardening machine tool

induction hardening machine tool gear quenching machine

gear quenching machine Rail Quenching Machine Tool

Rail Quenching Machine Tool half shaft induction hardening machine

half shaft induction hardening machineApplication : The complete set of equipment has the functions of continuous quenching, simultaneous quenching, segmental continuous quenching, and simultaneous quenching. It is mainly used for the surface of various shaft parts such as semi-axle, drive shaft, camshaft, spline shaft and gear shaft. Quenching, induction quenching of gears, rings, sprockets and flat parts.

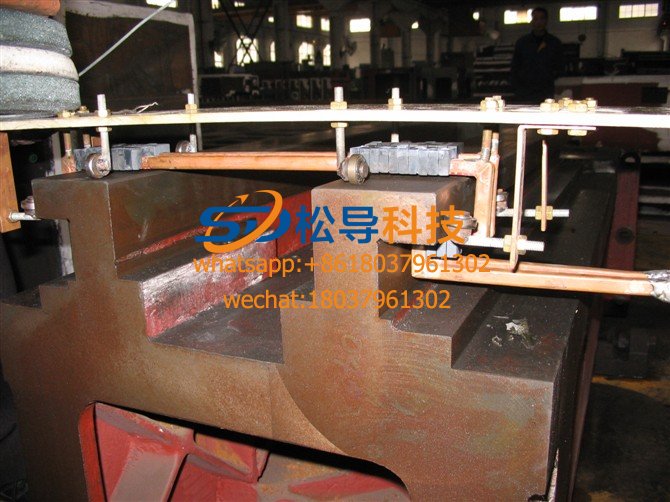

First, the special equipment for piston rod quenching mainly includes :

Induction heating power supply, quenching machine, water cooling system and inductor are composed of four parts. The surface of the piston rod can be quenched and heat treated. It can also be used with other equipment to form a production line. The quenching effect is quite good.

Second, the performance characteristics of the special equipment for piston rod quenching:

1. Fast heating: The fastest heating speed of the complete set of piston rod quenching equipment is less than 1 second, and the heating speed can be adjusted and controlled.

2 , power consumption: thermal efficiency of more than 95% , so compared to other heating methods (such as gas, oxygen, acetylene, coking coal, electric furnace, high-frequency tube, etc.) are energy-saving.

3 , the effect is good: the surface of the workpiece is heated evenly, the temperature rises quickly, and the degree of deformation of the oxide layer and the workpiece on the surface of the workpiece is reduced.

4 , wide application: special equipment for piston rod quenching can heat metal workpieces. (Induction loops are made according to the shape of the workpiece)

5 , less land: the equipment is small, light weight, occupying less than half a cubic space, easy to move and move.

6. Good environmental protection: no noise, pollution and open flame, it is easier to meet the requirements of environmental protection and fire protection.

7 , easy to operate: CNC design, the whole machine does not require debugging, installation, operation is very convenient, you can learn in 5 minutes.

8. High efficiency: The complete set of equipment for piston rod quenching has automatic setting function, and the operation can be completed by one person, thus reducing the number of processes and improving efficiency.

Third, why should the piston rod be quenched?

We all know that the piston rod has a certain hardness on the surface. So, do we know which processing steps it has? One of the most important steps is to quench, then everyone knows why we have to quench the piston rod?

From the course of use, we can understand that the processing of the piston rod is not so simple; he needs special equipment to complete; and the requirements for the piston rod in various productions are also very high; if the piston rod is not quenched or If the treatment is not good, it will seriously affect the production efficiency and the service life of the workpiece. When quenching the piston rod, we should choose the appropriate power supply. We must pay attention to the fact that the piston rod can not be too large or too small; the general intermediate frequency power supply is The most used; and the power saving is better, this piston rod manufacturer can be determined according to the requirements of the piston rod; the uniformity is better when quenching, so that the piston rod processed by the quenching equipment can meet the production requirements; The usage time can also be extended a lot.

Everyone knows that there are many kinds of piston rod quenching equipment; various workpieces can be quenched; but different workpieces have different requirements during quenching; due to the particularity of these workpieces, some special equipment is needed during quenching. Therefore, the effect achieved after quenching will meet the requirements.

Fourth, the specific operation of high frequency quenching piston rod high frequency quenching

The piston rod is a connecting part that supports the work of the piston. Most of them are used in the cylinder and cylinder movement executing parts, and are a moving part with frequent movement and high technical requirements. Taking a hydraulic cylinder as an example, it consists of a cylinder, a piston rod (cylinder rod), a piston, and an end cover. The quality of its processing directly affects the life and reliability of the entire product. High processing requirements of the piston rod, a surface roughness is Ra0.4 ~ 0.8 μ m, concentricity, wear resistance demanding.

The piston rod has an important process called induction hardening, so how do we perform high frequency quenching?

Specific operating rod induction hardening induction hardening, is as follows: After the rough grinding, is an intermediate or high-frequency quenching treatment, and that the induction heating to 1000--1020 of using compressed air injection cooling, the quenching it hard layer depth of 1.5 - 2.5mm. After quenching, it is also straightened. After that, it is tempered at 200 to 220 degrees and kept for 1 to 2 hours, so that the hardness after cooling can reach above HRC50 . The high-frequency quenching of the high-frequency quenching piston rod is a heat treatment method that causes a certain induced current to be generated on the surface of the piston rod, and then rapidly heats it, and then rapidly quenches it. The main purpose is to obtain the martensite structure in a certain depth range of the piston rod surface, and the core portion still maintains the state of the structure before quenching, thereby making the surface hardness of the piston rod reach the standard, and the plasticity of the core portion thereof. Resilience is up to standard.

6, piston rod heat treatment What are the benefits?

After the quenching and tempering treatment, the piston rod obtains good comprehensive mechanical properties and is ready for the subsequent surface treatment. The purpose of surface hardening is to obtain a high surface hardness to support the surface chrome plating layer, thereby improving the wear resistance and corrosion resistance of the piston rod. The stress relief annealing is arranged before the electroplating after the grinding process to completely eliminate the residual stress inside the piston rod, improve the plating quality and the product qualification rate, and improve the service life of the piston rod.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved