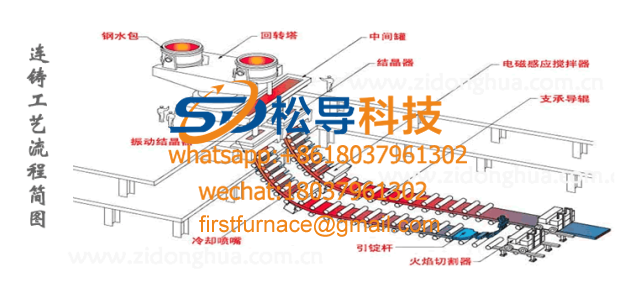

Continuous casting machine vibration device

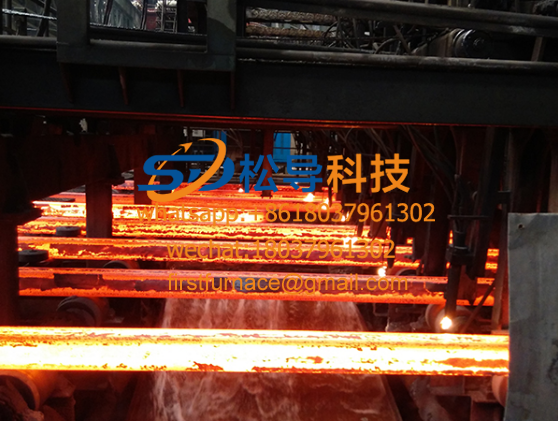

Continuous casting machine vibration device continuous casting machine equipment

continuous casting machine equipment Straightening machine

Straightening machine Continuous casting machine shaker

Continuous casting machine shaker Continuous casting pusher

Continuous casting pusher Billet shearing device

Billet shearing device Tubing machine details

Tubing machine details Continuous casting machine crystallizer

Continuous casting machine crystallizer Continuous casting machine XF--II type straightening machine

Continuous casting machine XF--II type straightening machine continuous casting machine

continuous casting machineIn recent years, according to the experience of foreign motor winding wire device applications, use of a new coiler --725 rev / min horizontal line discharge machine (hereinafter referred to as the discharge line machines), the structure having a pulley ratio Simple, light weight, low power required, and flexible.Discharge line arranged to achieve the advantages of bulk machine finished cooling roll, is a relatively reasonable factory finished output wire mill, since the water take-up device would like.

Contact us will have a very low price, please consult the specific price. firstfurnace@gmail.com

I plant in the transformation of wire rod rolling mill and spiral wire transfer truck it must pass from the pond, over the comparative advantages and disadvantages of various performance winding machine, for which we re-double in a four-wire rolling mill at adoption The horizontal potting machine was used to replace the original pot-type reeling machine , and the line was arranged in tandem . See Figure 巳 for good results. The nominal line speed of the complex double finished product frame after the transformation of the wire workshop of our factory is 10.38 m / s. In order to use the discharge line at a machine speed is low, we added before discharge machine wire helical coiled coil head of a dispersion, the finish rolling toggle plate is not out of line helical coiled tail, using a ring head bulk volume Out. The threading machine has achieved satisfactory results in use , fully demonstrating its superiority and its performance.

Mechanical domestic wire line production purports spouting discharge machine rolled coil is formed mostly used Bell reel, with the proviso that: a multi-jaw reel, reel underground multi-column. The major drawback of these reeling machines is their inability to accommodate high speed, flawless wire rolling. The need for centrifuges and controlled cooling for the rolling stock in the threading machine ; the horizontal ( or vertical ) threading machine is a new type of running resistance of the rolled piece in the spiral tube which is suitable for the new process requirements of wire production. Take the device. Raise wire rod production, quality; increasing the coil weight, improve product of great economic significance. It is simple in structure and reliable in operation.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved