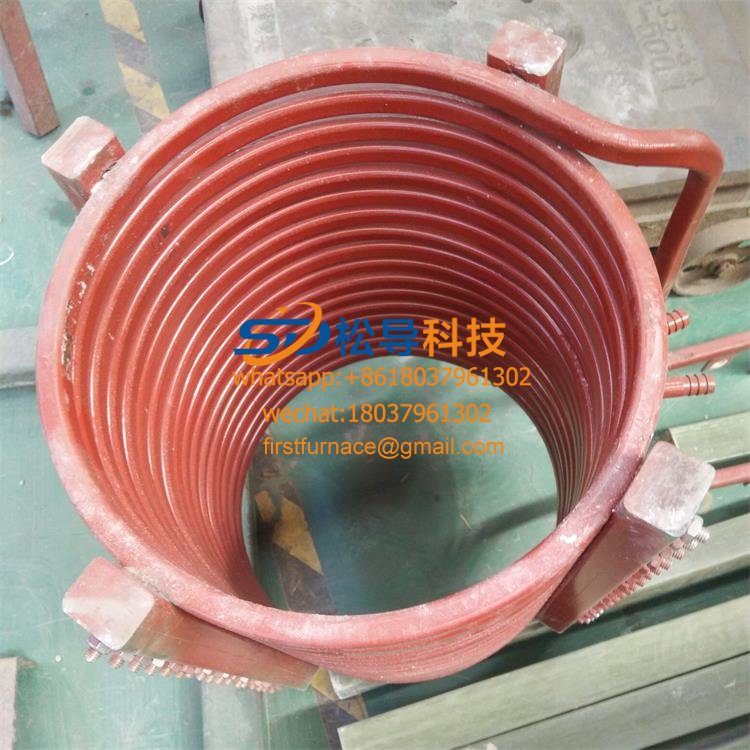

Induction melting furnace reactor water-cooled coil inner dia

Induction melting furnace reactor water-cooled coil inner dia 3 tons induction furnace coil customize

3 tons induction furnace coil customize 315 square water cooled cable used for intermediate frequency

315 square water cooled cable used for intermediate frequency Silicon carbide graphite crucible used for aluminum melting c

Silicon carbide graphite crucible used for aluminum melting c Portable smelting thermometer for melting furnace

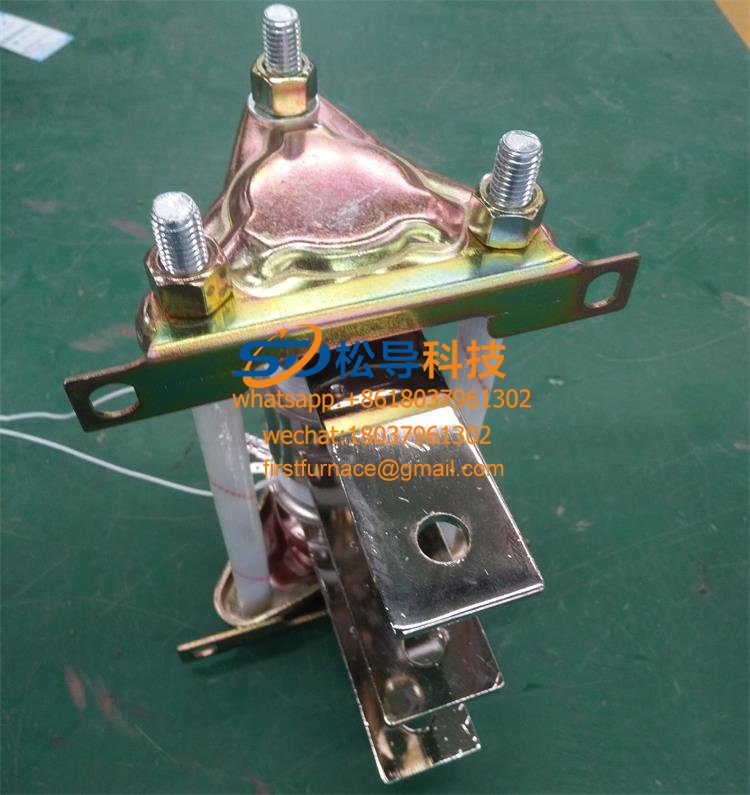

Portable smelting thermometer for melting furnace Water-cooled Reactor used for IF/MF induction furnace

Water-cooled Reactor used for IF/MF induction furnace Reactor used for induction furnace electric furnace

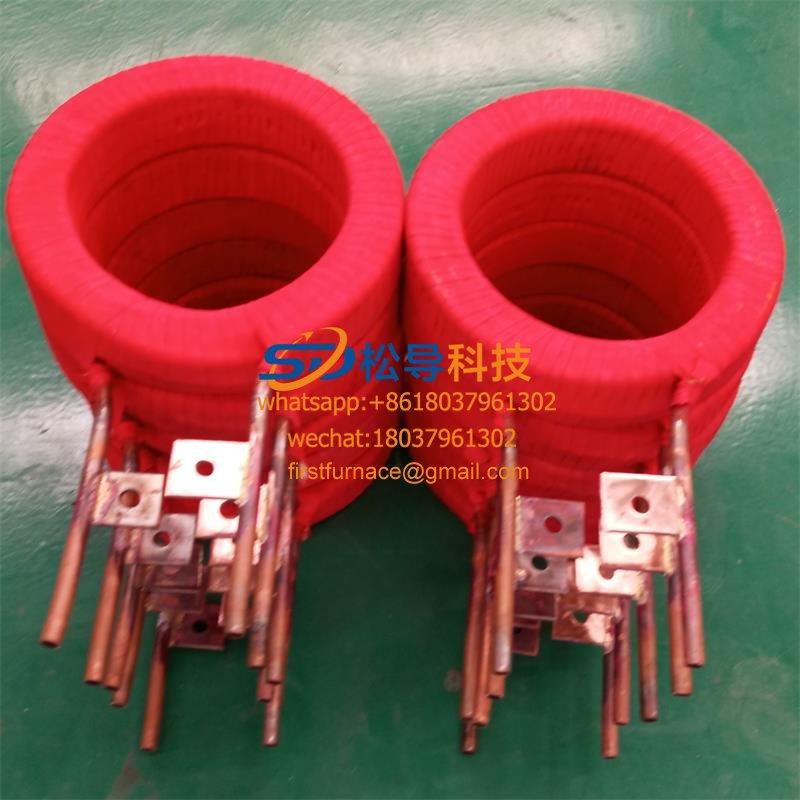

Reactor used for induction furnace electric furnace T2 induction Copper Coil Of Electric Induction melting furnac

T2 induction Copper Coil Of Electric Induction melting furnac 315 square water-cooled cable for medium frequency furnace c

315 square water-cooled cable for medium frequency furnace c MPU-6 constant power control board

MPU-6 constant power control board Techsem thyristor KK2000A2000V,intermediate frequency furnace

Techsem thyristor KK2000A2000V,intermediate frequency furnace induction melting furnace SS13 double thyristor water cooled

induction melting furnace SS13 double thyristor water cooled  SS12 double thyristor heat sink for steel melting furnace

SS12 double thyristor heat sink for steel melting furnace Water cooled radiator for medium frequency furnace

Water cooled radiator for medium frequency furnace reactor water cooling coil for Copper melting furnace

reactor water cooling coil for Copper melting furnace Intermediate frequency furnace reactor coil

Intermediate frequency furnace reactor coil 150 kg medium frequency furnace coil, inner diameter 320 mm

150 kg medium frequency furnace coil, inner diameter 320 mm 350 kg medium frequency furnace induction coil

350 kg medium frequency furnace induction coil 100 kg aluminum shell medium frequency furnace induction co

100 kg aluminum shell medium frequency furnace induction co KK2500A2500V used for 3T induction melting furnace

KK2500A2500V used for 3T induction melting furnaceElectric Building Lining Machine for Induction Furnace,the price is 1600RMB

Professional intermediate frequency furnace lining tool - building furnace

With the development of the times, more and more work has embarked on mechanization, as has the foundry industry. The dirtiest and most tiring in the foundry industry is a furnace, dust pollution is particularly serious, and no more money workers are Willing to do, even if it is done, the strength of people is limited, the strength of the knotting process can not be the same, but the strength of the machine will not change, the general trend, so the furnace is gradually entering market.

Nowadays, the medium frequency melting furnace is widely used in the foundry industry. The intermediate frequency furnace has become the main smelting equipment for casting enterprises to produce castings. However, the service life of the intermediate frequency furnace lining has become an important factor affecting the efficiency of casting enterprises and the quality of castings. The traditional lining knot is artificial knotting. The disadvantage of this method is that it is neither reliable nor time-consuming and laborious. The method of using the electric building machine to vibrate in the furnace body can save the furnace building time and greatly improve the smelting production efficiency.

First, we will introduce the furnace building machine. There are two types of furnace building machines on the market: one is an electric furnace, and the other is a pneumatic furnace.

The principle of the knotting material of the electric building machine is to generate the vibration by the motor to drive the tamping, and directly knot the charge, and use the vibration force to make the size particles of the charge fill each other to achieve the vibration effect.

The pneumatic building machine is to put the machine into the interior of the crucible, and by vibrating the inner wall of the crucible to generate vibration, the crumb-sized particles are filled with each other to vibrate the charge.

Seeing this, some friends may have seen it. No matter whether it is pneumatic or electric, the choice of furnace materials must be dry material. The wet material has poor fluidity. It is difficult to achieve good vibration through this vibration principle. effect.

The advantages of building a furnace compared to traditional manual knotting:

Anyone who knows and is familiar with the intermediate frequency furnace knows that before the furnace building machine appears, the lining of the original intermediate frequency furnace needs to be manually completed, and at least 4-5 knotting workers are needed in the knotting process. It takes at least 12 hours or so to be strong. After the appearance of the furnace building machine, this problem has been solved very well, and it has the following obvious advantages compared with the manual knotting. The lining made by the electric building machine can be used for 1-2 people, and the furnace building time is greatly shortened. The average life expectancy is increased by 10%, and if experienced, it can be increased by 15%-20%.

Taking the 1T furnace as an example, the same lining material, the furnace building machine and the artificial knotting are compared as follows:

First, artificial knotting

1, personnel needs: about 4--5 people, but also need relatively experienced;

2, knotting time: about 12 hours, individual circumstances may be about 10 hours;

3, knotting method: personnel rotation 2 people with a hand tool for beating, every 5 minutes to change, because the dry sand exhaust is more powerful, repeated artificial force after repeated artificial will be more tired;

4, knotting firmness: the size of the workers is different, and the later the strength is smaller, the firmness of the knot is relatively weak;

5, knotty uniformity: because each time the strength of the workers is different, each time the force is different, the knotting uniformity is weak;

6. Stability of the lining life: Because the artificial knotting firmness is different each time, the uniformity around the wall of the knotting furnace is different, the furnace age is not stable.

Second, the furnace is knotted

1. Personnel requirements: 2 people, can operate according to the requirements of use, easy to learn;

2, knotting time: 4-5 hours, electric furnace building machine is not the longer the knot, the better, according to the requirements to operate;

3, knotting method: one person operation, one person assist, use both hands to stabilize the body without manual force;

4. Knotting compactness: According to the capacity of the furnace body and the amount of feeding, the vibration force of the furnace can be adjusted, which can be adjusted between 1000-2000N. After the requirements are finished, the compactness is very obvious;

5. Knotting uniformity: After the vibration force is adjusted, the vibration force generated each time is very uniform, and the vibration frequency is high, which is convenient for continuous exhaust of sand;

6, lining life: very stable, each time using the same workers, materials, operating procedures, the difference is within 10 furnaces.

The average life expectancy of the furnace lining knotted by the furnace can be increased by 10%, and if experienced, it can be increased by 15%-20%.

The pneumatic furnace building machine is an upgraded version of the electric building furnace. It only needs to be a bracket to hoist the machine and put it into the raft. It can be used on the air. It takes 10 minutes to lift it up. It is more labor-saving than electric power. The knotting speed is faster, and the workers are directly liberated from the work of the furnace.

PREV:No More Articles.

NEXT:315 square water cooled cable used for intermediate frequency induction furnace

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved