Bearing sleeve heater

Bearing sleeve heater Gear heating automatic equipment

Gear heating automatic equipment Rolling mill bearing heater

Rolling mill bearing heater DM-1000steam turbine guardring induction heater

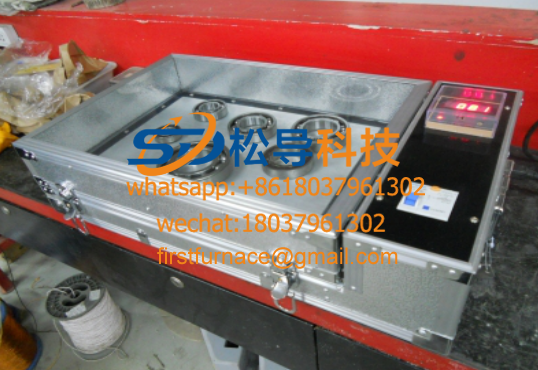

DM-1000steam turbine guardring induction heater Flat bearing heater

Flat bearing heater Pulley heater

Pulley heater Inner bore bearing heater

Inner bore bearing heater Ds-2000 Induction Heater-Hub Heater

Ds-2000 Induction Heater-Hub Heater Combined bearing heater

Combined bearing heater Multi-station drum induction heater

Multi-station drum induction heater Multi-station gear heater

Multi-station gear heater Gear heater

Gear heater Gear heating with automatic equipment

Gear heating with automatic equipment Gearbox housing heater details

Gearbox housing heater details Ds-1000bearing induction heater

Ds-1000bearing induction heater Ds-800 steam turbine guard ring induction heater

Ds-800 steam turbine guard ring induction heater Ds-600 bearing induction heater-bearing induction heater

Ds-600 bearing induction heater-bearing induction heaterBearing combination heater detailed introduction

name: | GHJ- H combined heater |

power: | 2.0-10 KW |

Voltage and current: | 220V/380V 9-15A |

Suitable bearing outer diameter: | 30-400mm (multiple units) |

Suitable bearing width: | 9-100mm |

Maximum bearing load: | 50Kg |

Machine quality: | 45Kg |

GHJ- H combined heater parameter table

power | 2.0-10KW | temperature control | 0 - 180 ° C |

Voltage | 220V/380V | time control | 0 - 99'59'' |

Current | 9-15A | Continuous installation | Have |

Adapt to bearing outer diameter | 30-400mm | Temperature retention | Have |

Adapt to bearing width | 9-100mm | Automatic demagnetization | Have |

Maximum bearing weight | 50Kg | Power self-adjustment | Have |

Number of assembled bearings at one time | Optional | Control panel (display) | Digital display |

automatic / manual | Optional | Forced air cooling | Have |

Host weight | 45Kg | Overheating protection | Have |

Product performance characteristics:

The enclosure features a fully shielded , compact , rugged metal case that minimizes magnetic field radiation.

Air-cooled heat dissipation avoids the disadvantages of water-cooled mode installation and inconvenient daily maintenance.

This heating device is specially designed for the production of "angular contact bearing" manufacturers. The induction heating device can quickly heat the outer ring of the bearing to expand and easily complete the bearing assembly. In order to adapt to the assembly requirements of different bearing models, a host with a number of sensors is used to expand the assembly range and save money. The "assembly induction heating device" can improve the production efficiency and avoid the pollution of the outer ring of the bearing due to the heating of the oil bath. Compared with the existing "flat heating" and "oil bath heating" efficiency is more than 5 times, energy saving is more than 80% , convenient and fast, no pollution, and the product quality is greatly improved. Using induction heating technology, the automatic assembly of the bearing can be easily realized, the human intervention behavior of the bearing in the assembly process is reduced, the precision of the assembly is improved, and the quality of the bearing is improved.

Working in the super audio section, no noise pollution.

The timing heating mode can be used in 99 minutes and 59 seconds.

The workpiece is automatically demagnetized.

The latest micro-processing technology, the lowest energy consumption. Easy to operate, the whole process can be controlled.

PREV: Gear heating automatic equipment

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved