Rolling mill detailed introduction

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production lineIt mainly produces rolling mills, cold rolling mills, hot rolling mills, aluminum foil rolling mills, four-roll mills, rolling mill parts and ball mills. We provide free installation, commissioning and training of technicians and other related services. Users are welcome to come to consult and negotiate.Contact us will have a very low price, please consult the specific price. firsTfurnace@gmail.com

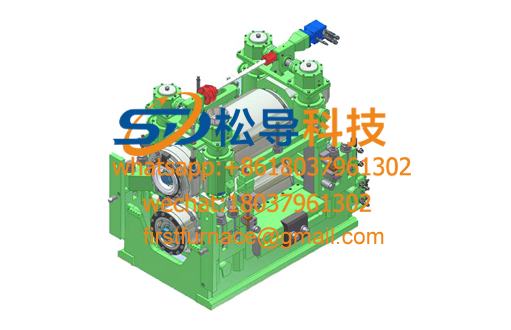

1. Overview of universal mill

The universal rolling mill is composed of a pair of horizontal rollers and a pair of vertical rollers. The axis of the four rollers is in one plane, the horizontal roller is the driving roller, and the vertical roller is the driven roller (some rolling mill vertical rollers can also be driven). The rolling stock can be processed on four sides, and the two-roll horizontal rolling mill can be used as an auxiliary frame (edger).

2 , the purpose of the universal mill

The universal rolling mill is mainly used for rolling various types of steel, such as: H- beam, rail, I-beam, channel steel, steel sheet pile, U- shaped steel, L- shaped steel, unequal angle steel, etc., because it is suitable for many types of steel. The variety of steel is rolled, hence the name "Universal Mill".

3, the device structure of the universal mill process, a layout method

1. The complex section hole type consisting of four rollers can compress the components on the section at the same time, the deformation of the rolled piece is uniform, the speed difference around the section is small, and the internal stress of the rolled piece is small.

2. It is possible to use a roll with a smaller diameter (because it is not necessary to groove on the roll) to roll a product with a higher leg and a wider waist, and to have no slope on the inside of both legs. This is difficult to achieve on a conventional two-roll mill.

3. The reduction of the leg and waist of the rolled piece can be adjusted by itself, which simplifies the adjustment of the rolling mill during rolling.

4 , high rolling precision, less wear and tear, energy consumption.

4 , universal mill selection method

The form of the universal rolling mill is divided into four types according to the structure, namely, closed type, UD (Universal-Duo) prestressed type, SC (Schloemann-Siemag compact stand) connecting plate three type and short stress line type rolling mill. The common closed frame consists of a closed arch, upper and lower horizontal rolls and housings, and a universal base for the vertical roll box. When changing rolls, the horizontal and vertical rolls and their housings can only be accessed from the side of the arch window. Because the horizontal roller diameter of the universal rolling mill is large, the vertical roller roller seat is also large in volume, and the width of the arch window must be larger than the above two. Therefore, the upper beam of the frame is wider, the column is higher, the equipment is large, and the rigidity of the frame is also Poor.

The UD prestressed / short-stress frame consists of a lower frame with lower horizontal rollers and housings, an upper frame with upper horizontal rollers and housings, and a central part with vertical rollers. These three parts are respectively connected by four hydraulic prestressed tie rods, which can be swung out to the outside, and the prestress applied can be more than twice the large rolling force. The UD rack roll is lifted from the top. The size of the frame window is only related to the size of the roll neck and the bearing seat. Therefore, the window width can be reduced by 40% , the column height can be reduced by 20% , and the bending of the beam under the rolling pressure is reduced. One-third, with the same cross-sectional dimensions of the columns and beams, the UD frame stiffness is approximately three times that of a closed frame .

The two arches of the SC frame are not on either side of the horizontal roller, but are arranged in front of and behind the roller, and the arch is connected to the upper and lower beams by a connecting plate. During rolling, the frame arching plate becomes a steel plate in a plane-stressed state under the action of rolling force, so that the strength and rigidity of the entire frame are improved, and the top and sides of the frame are all open, and the roll changing is convenient. The frame adopts an eccentric structure to adjust the opening degree of the horizontal roller and the vertical roller, and the range of the adjustment book is small, which is suitable for the continuous rolling unit.

There is no ordinary arch in the short-stress line mill. The part subjected to the rolling load is a high-rigidity closed frame. The vertical direction of the horizontal roller is composed of two upper beams and two lower beams connected by a tie rod. In the system form, the four pressing screws are integrated with the tie rods, which can adjust the upper and lower beams symmetrically to the rolling line. Compared with the closed frame, the rigidity is good, and the weight of the equipment is only the ordinary closed frame. Two-thirds. At present, most of the small and medium-sized production lines at home and abroad use this type of machine.

UD pre-stressed racks and SC- connected panel racks are generally used to produce medium and small-sized products with H400 - 500mm or less. Large-size H- beams are commonly used in closed-end universal racks and compact rack mills. The Maanshan Iron and Steel Co., Ltd. adopts the H- shaped steel of H200-600mmby adopting the yoke closed type universal frame rolling mill . The main features of this rolling mill are: when the roller is changed, the yoke frame is opened, the vertical roller is removed from the frame opening, and the yoke structure is adopted, which can increase the thickness of the frame to increase the rigidity of the rolling mill and improve the rigidity of the closed frame.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved