Medium frequency induction heating copper tube annealing eq

Medium frequency induction heating copper tube annealing eq Medium frequency induction heating copper wire annealing equi

Medium frequency induction heating copper wire annealing equi Copper hot rolling furnace

Copper hot rolling furnace  Copper tube medium frequency induction annealing furnace

Copper tube medium frequency induction annealing furnace Copper tube annealing medium frequency induction equipment

Copper tube annealing medium frequency induction equipment  Copper tube annealing equipment

Copper tube annealing equipment  Copper tube annealing furnace

Copper tube annealing furnace Copper pipe annealing

Copper pipe annealing Copper tube heat treatment annealing equipment

Copper tube heat treatment annealing equipment Copper tube induction heating continuous annealing production

Copper tube induction heating continuous annealing production Copper tube induction continuous annealing furnace

Copper tube induction continuous annealing furnace  Copper Tube Induction Heating Continuous Annealing Furnace

Copper Tube Induction Heating Continuous Annealing Furnace

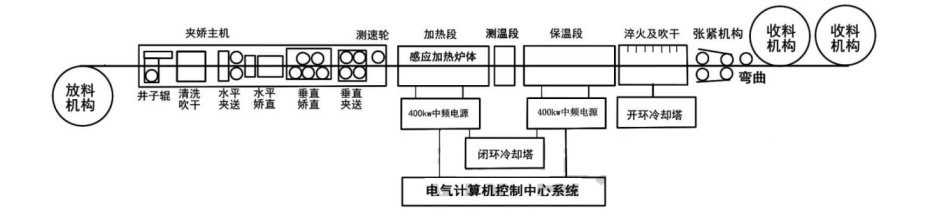

Brass by the continuous on-line annealing furnace discharge mechanism, a host folder straightening, frequency furnace is heated, circulating cooling-line system, drying means, the tensioning means, takeup speed devices and auxiliary systems, computer control group into the core system. In the continuous online annealing unit, the induction heating furnace is the core of the normal operation of the whole machine , and the computer automatic control system is the control core .

Copper tube continuous annealing line induction heating process in FIG.

2, copper tube induction heating continuous annealing production line process:

The discharge basket is in place—the copper tube passes through the nesting roller to the front pinch mechanism through the looper detection mechanism — cleaning the outer wall—blowing dry—horizontal straightening—vertical straightening—vertical pinching—induction heating—insulation—quenching cooling— Blow dry - pinch tensioning mechanism - receipt

Third, the induction heating brass continuous annealing line main technical parameters Summary

Serial number | name | specification | ||

1 | Heating material | Copper and copper alloy | ||

2 | Annealed pipe outer diameter | Φ6.0-22.0mm | ||

3 | Maximum wall thickness | 0.3-2.0mm | ||

4 | Annealing speed | 30~400m/min | ||

5 | IF power total power | 400KW | ||

6 | Tube maximum annealing temperature | 550 ° C | ||

7 | Normal annealing temperature of pipe | 400-450 ° C | ||

8 | Basket specifications | Φ3050×1500mm | ||

9 | Maximum material weight | 600kg | ||

10 | Maximum rewinding and reeling drive capability: | 2000kg (+ pocket copper pipe) | ||

11 | Annealing copper tube quality standards: | Conforms to current national standards | ||

12 | Retracting roller | Two stations | ||

13 | Control the total power of the power supply | 9 0kW | ||

14 | Total installed power of the unit | 900 kw | ||

15 | Total weight of equipment | 30T | ||

16 | Hydraulic system pressure | 100kgf/cm2 | ||

17 | Hydraulic system flow | 10L/min | ||

18 | Compressed air pressure | 4-7kgf/cm2 | ||

19 | Compressed gas dosage | 120-200Nm3/h | ||

20 | Nitrogen pressure | 3-5kgf/cm2 | ||

twenty one | Nitrogen flow | 60-80Nm3/h | ||

twenty two | Power closed loop cooling tower | |||

twenty three | Open loop cooling tower | |||

twenty four | Floor area

| Unit width 12620mm The center of the unit is 1100mm high Total length of the unit 27050 Mm The total height of the unit is 2200mm Retracting center distance 24000 mm | ||

25 | Total installed capacity ( 1000 kW) | |||

Furnace type | IF power total power | Total motor power | Control power supply | |

TL400/×4 0 0 | 2×4 0 0 | 80 | 10 | |

The main technical specifications of the copper tube induction heating continuous annealing production line are as follows:

Specification code | SD 400/2×450 |

Maximum annealing speed (m/min) | 400 |

Intermediate frequency power supply nominal power (kW) | 400KW |

Annealed pipe maximum outer diameter (mm) | 28.0 |

Annealed pipe minimum outer diameter (mm) | 7.0 |

Tube maximum annealing temperature (°C) | 550 |

Normal annealing temperature of pipe (°C) | 450 |

Fourth, copper tube induction heating continuous annealing production line supply range and price

Serial number | Name and model | Quantity | Remarks |

1 | Discharge mechanism | 1 set | Active unwinder discharge motor AC5.5KW |

2 | Folder host | 1 set | |

2.1 | Cleaning device | 1 set | |

2.2 | Horizontal straightening machine | 1 set | Straightening motor AC30KW |

2.3 | Vertical straightening machine | 1 set | |

2.4 | Length gauge device | 1 set | |

3 | SCR intermediate frequency power supply | 2 sets | 400KW / 6KHZ nitrogen protection system |

4 | Quenching and cooling blow dryer | 1 set | |

5 | Tensioning mechanism | 1 set | |

5.1 | Traction device | 1 set | |

5.2 | Pre-bending mechanism | 1 set | |

6 | Receiving device | 2 sets | Receiving motor AC5.5KW |

7 | Straightening mechanism hydraulic system | 1 set | 100kg/cm2 |

8 | Straightening mechanism electronic control system | 1 set | Low voltage distribution cabinet and PLC control |

9 | Closed loop cooling tower | 1 set | ZXZ-N20 / 40T medium frequency power supply |

10 | Open cooling tower | 1 set | K-100T quenching cooling device |

11 | Cooling line and valve | 1 set | All cooling lines |

12 | Cable wiring and piping | 1 set | All lines and cables |

11 | Computer control core | 1 set | Industrial computer control and monitoring |

12 | Temperature measurement system | 1 set | |

13 | Transportation costs | ||

14 | Commissioning installation costs |

V. Introduction to mechanical equipment

The unit consists of unwinding machine, unwinding looper, horizontal pinch feeding roller, cleaning device, straightening device, traction mechanism, pre-bending device, receiving device and electronic control system.

1. Power unwinding machine: It consists of motor, reducer, frame, tray and brake device. The high-material frame of the Φ3050X800mm (1500 mm) disc puller is allowed to be placed on the tray, and the coiled tubing is used as the raw material of the wound pipe.

Unwinding motor: AC change Y112M-4 5.5KW 1440r/min.

2. Unwinding looper: consisting of bracket, support arm, idler, vertical roller, swing arm and other components. It supports the pipe to a certain height through the roller, guides the pipe by the vertical roller, and smoothly introduces the horizontal pinch from the tray. Pair of rolls. The rotation speed of the unwinding disc is the swing angle of the swing arm, and the swing ratio is amplified by a pair of gears, input into the computer system, the frequency is adjusted, and the rotational speed of the turntable is controlled to achieve the synchronization of the whole machine speed. The torsion spring is used to control the swing angle and adjust the torsion spring force according to the diameter of the pipe.

3. Horizontal pinch-to-roller: Two pairs of horizontal pinch rolls are used to feed the pipe into the cleaning device, and both pairs of pinch rolls are driven passively.

4. Cleaning device: mainly for cleaning the surface of the tube blank and dust, the cleaning medium is the surface cleaning agent of the copper tube , and is directly supplied by the cleaning pump station. The entire cleaning process is fully enclosed.

5. Straightening device: consists of a vertical straightener and a horizontal straightener, which work together to straighten the copper tube . The vertical and horizontal straightening machines are all nine-roller active straightening, four-roller stipulation, and the five-roller can be adjusted by hand wheel alone.

6. Traction mechanism: transmission through the crawler type.

7. Receiving device: consists of turning mechanism, beam, material frame and so on. After the tube blank is sawn off, the rear feed roller accelerates the tube blank to the turning mechanism, the length of the discharge roller path is greater than 4 m, and then the finished tube is turned into the adjacent material frame.

8. Electronic control system: It adopts PLC centralized control, adopts AC frequency conversion technology to control the start, stop, acceleration and deceleration of discharge and feeding motor, AC servo system and relay control system control. The electronic control system consists of an electric control cabinet, an operation console and an operation box.

9. Hydraulic system: Mainly used for lifting cylinders of the winding table.

10. The water cooling section: passing through the cooling spray cooling and immersion cooling section two brass is cooled to room temperature, the brass can be controlled by adjusting the temperature of the cooling tank into the water, the optimal temperature is 60 ~ 80 ℃ .

11. The direction of the pay-off reel is: clockwise to take the line, the take-up reel takes the line direction: counterclockwise to take the line.

Copper tube induction heating continuous annealing production line This control system has what are the characteristics:

(1) The drive system of the receiving and discharging mechanism and the clamping mechanism adopts a series of vector controllers, and the driving system of the tensioning mechanism adopts a DC controller.

(2) The computer system adopts Taiwan Advantech . The operating system xp can implement networked control .

(3) human-machine interface using Samsung 23-inch LED screen touch screen is very easy to operate and commissioning personnel monitoring system.

(5) Application software In addition to the conventional logic control, the tube induction continuous annealing controller application software has the following functions:

1P-V (power-speed) automatic follow function. Intermediate frequency power supply according to pipe specifications and annealing process requirements

The output power automatically follows the change in copper tube speed to ensure stable annealing temperature. TL400 copper tube 20 at a speed 400m / min continuously adjustable.

Found ② The control voltage calculating frequency power supply module. The method is simple and reliable, and is not subject to temperature measurement devices.

Measure the impact of the power system operating state. The precise power control model guarantees the control accuracy of the annealing furnace.

3 copper tube micro tension control function. The copper tube is automatically built during the heating process, so that the copper tube is annealed

Not stretched or shrunk in the state.

4 receiving and discharging speed compensation function. Use the loop detection and collection and discharge speed compensation calculation to ensure the receipt of the basket,

The discharge speed follows the linear velocity of the annealed copper tube , and the discharge is stable and the material is balanced .

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved