Bridge shell medium frequency induction heating furnace

Bridge shell medium frequency induction heating furnace Steel tube heating furnace

Steel tube heating furnace Bar intermediate frequency induction heating furnace

Bar intermediate frequency induction heating furnace 1000KW bar medium frequency induction heating furnace

1000KW bar medium frequency induction heating furnace induction metal heater

induction metal heater medium frequency induction heating machine

medium frequency induction heating machine medium frequency semi-automatic heating furnace

medium frequency semi-automatic heating furnace medium frequency induction heating furnace

medium frequency induction heating furnace medium frequency heating furnace

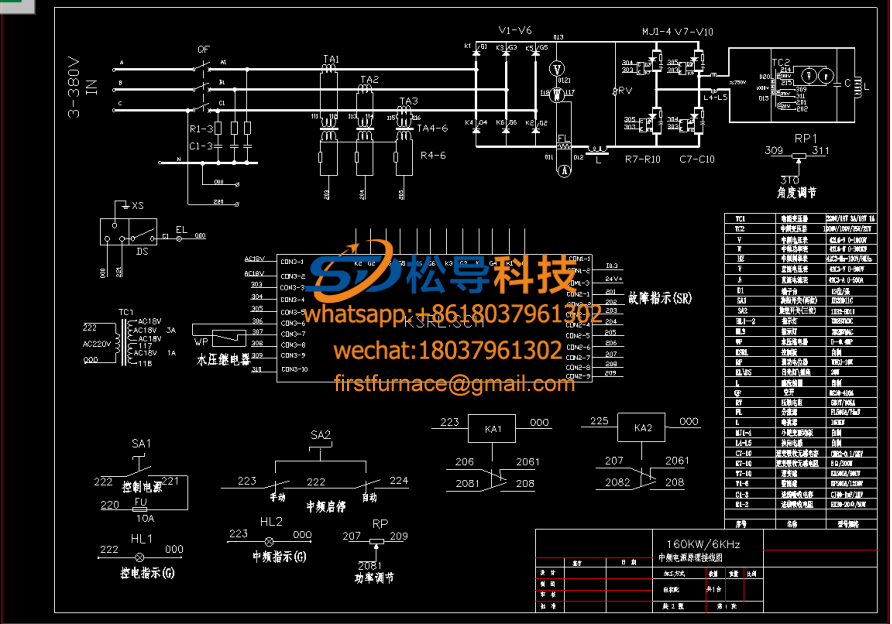

medium frequency heating furnace 160kw medium frequency induction heating furnace electrical s

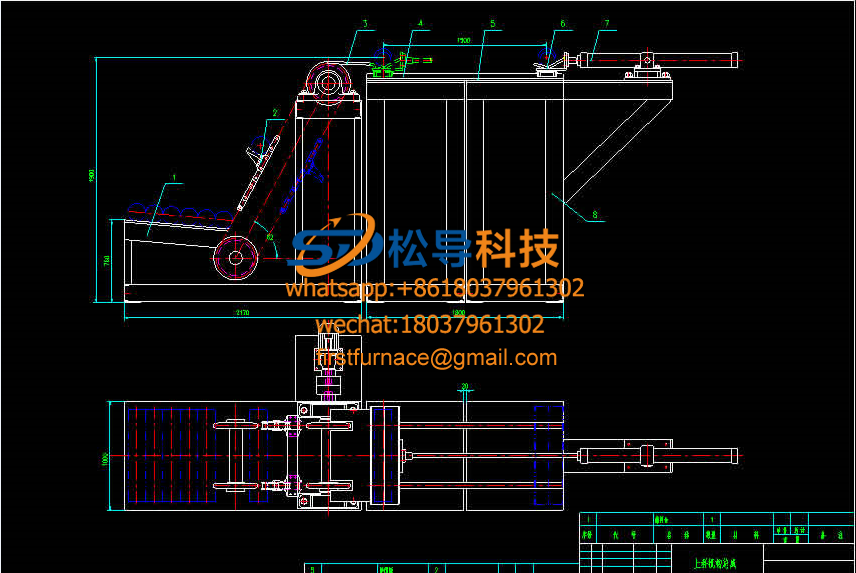

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

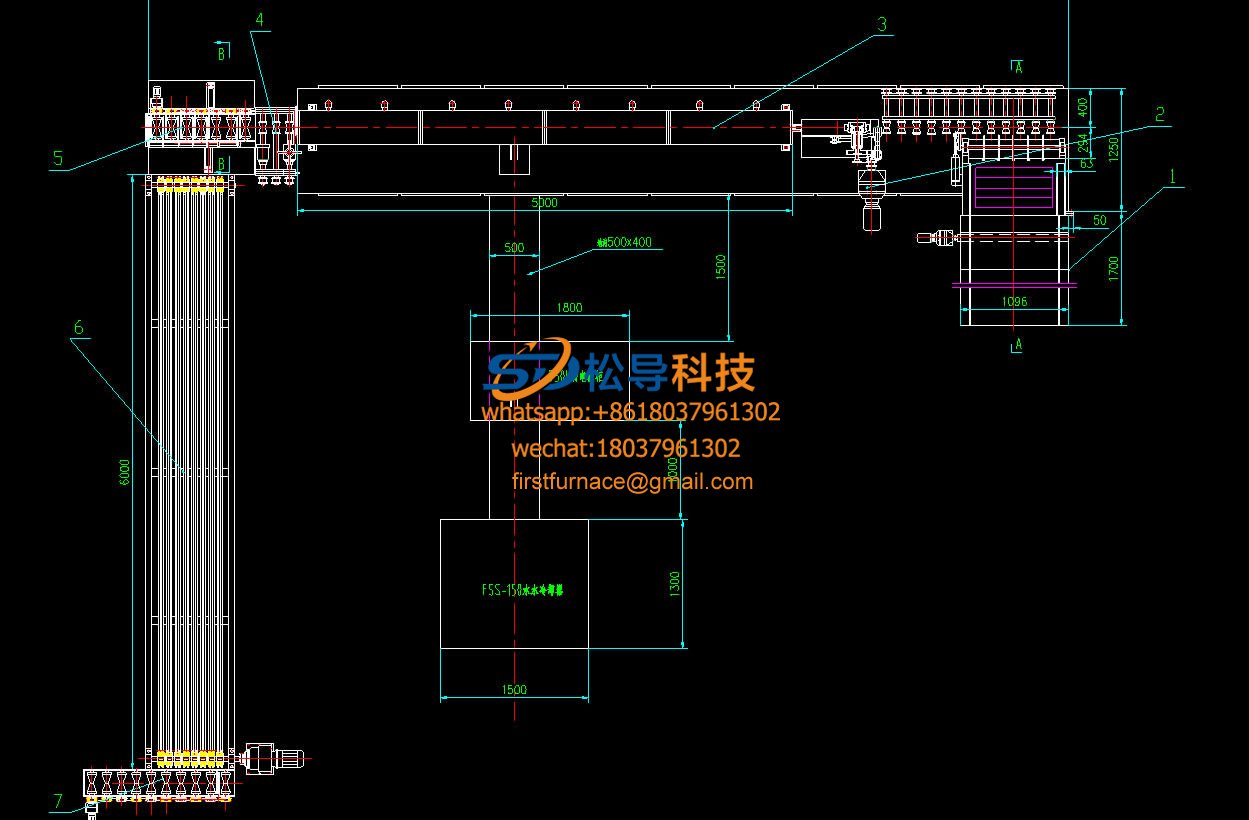

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

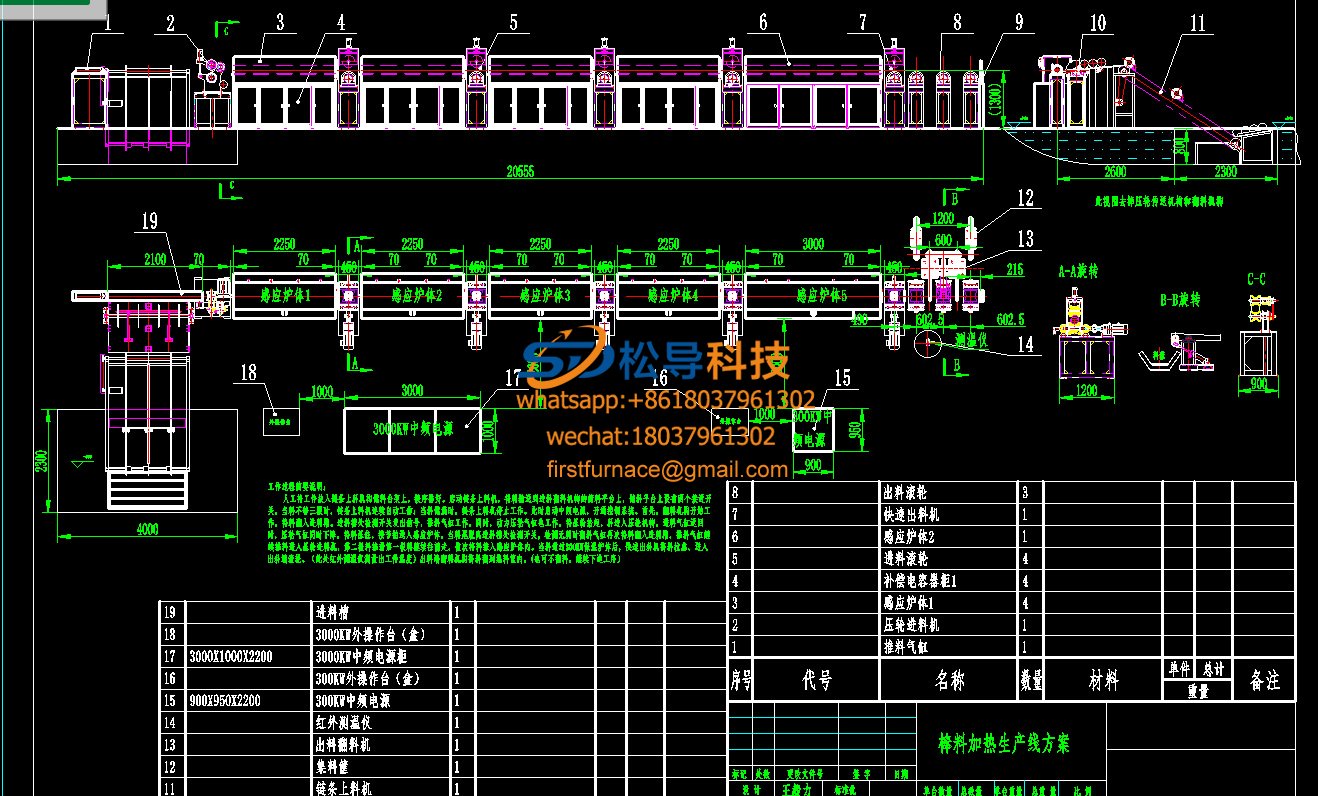

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

billet induction heating furnace coilA, steel tube heating furnace:

According to the buyer technical requirements, we need to steel furnaces include frequency power station 1, station 1 and a compensation capacitor counter stage furnace body.

Steel pipe heating furnace process conditions and technical parameters :

1. Heating temperature: 900 °C ~ 1000 °C

2. Steel pipe dimensions: outer diameter: Φ 350mm, wall thickness 8-16mm ;

Heating the steel pipe furnace technology selection method

Serial number | power | Steel pipe outer diameter | Steel pipe wall thickness | Heating temperature | heating time | Steel pipe speed |

1 | 500KW | Φ 350 | § 8 | 1000 °C | 156 seconds / meter | 380 mm/ min |

2 | 500KW | Φ 350 | § 16 | 1000 °C | 305 seconds / meter | 200 mm/ min |

3 | 1000KW | Φ 350 | § 8 | 1000 °C | 78 seconds / meter | 770 mm/ min |

4 | 1000KW | Φ 350 | § 16 | 1000 °C | 153 seconds / meter | 390 mm/ min |

B, IF power supply selects the latest development of IF power supply characteristics of our company .

1. Technical indicators:

1.1 , the startup success rate can reach 100%

1.2 , the rectification power factor is greater than or equal to 0.92

1.3 , with temperature interface for temperature closed loop control

1.4 , with internal and external conversion and automatic manual conversion

1.5 , all digital, no relay control loop, making the system stable and reliable

1.6 , with over-current, over-voltage, under-pressure, phase loss, water pressure, water temperature and other complete protection, to ensure that any faults are not damaged

2 , technical characteristics:

2.1 , medium frequency power supply

2.1.1 , the principle of the main circuit of the intermediate frequency power supply:

Due to the small power, the IF power supply can use 6- pulse waves, and its harmonics to the power grid will not exceed the standard. The principle of the main circuit is shown in the figure below.

C, steel tube heating furnace induction furnace body selection method

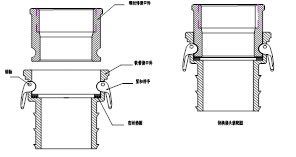

Because of the need to replace different sizes of sensors when heating steel pipes. We have fully considered its quick changeability in the manufacture of the sensor.

The furnace is designed with a fixed bracket that can be adjusted up and down. Through the adjustment of the manual worm gear lifter, the center lines of the furnaces of different specifications can be realized at the same height. It can effectively ensure that the steel pipe passes through the inductor smoothly without colliding with the furnace body.

Water quick change connector

For ease of operation, a quick-change coupling is used in the design of each water line joint, as shown in the upper right figure. Its material is made of stainless steel grade 316 . Mainly composed of threaded interface parts, hose interface parts, fastening wrenches, sealing washers, etc. The biggest feature of this quick-change joint is that the threaded interface parts and the hose interface parts can be matched with each other, and the fastening handle is convenient to operate and has good sealing performance.

Furnace lining

The furnace lining adopts silicon carbide or integral knotting method, and the use temperature is above 1450 °C, which has good insulation, heat insulation, and resistance to chilling heat and impact resistance.

Steel pipe heating furnace conditions

IF power supply: 380V ± 10% 50HZ

Transformer required capacity: 500KW: 600KVA capacity

1000KW: 1200KVA capacity

Delivery time of steel tube heating furnace : completed within 45 days after the contract takes effect .

Steel tube heating furnace composition and price :

500KW steel tube heating furnace offer:

Serial number | Steel tube heating furnace name | Quantity | price |

1 | KGPS-500KW/0.5KHz intermediate frequency power supply | One | 9 .5 |

2 | Compensation capacitor cabinet | One | 3.5 |

3 | Heating furnace | One | 3.0 |

4 | Furnace up and down adjustment mechanism | 1 set | 1.0 |

5 | Connect water-cooled cable and copper busbar | set | 0.5 |

Steel tube heating furnace total price: | |||

1000KW steel tube heating furnace offer:

Serial number | Steel tube heating furnace name | Quantity | price |

1 | KGPS-1000KW/0.5KHz intermediate frequency power supply | One | 16 .5 |

2 | Compensation capacitor cabinet | One | 4.5 |

3 | Heating furnace body GTR-350 | One | 3.0 |

4 | Furnace up and down adjustment mechanism | set | 1.0 |

5 | Connect water-cooled cable and copper busbar | set | 0.5 |

Steel tube heating furnace total price: | |||

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved