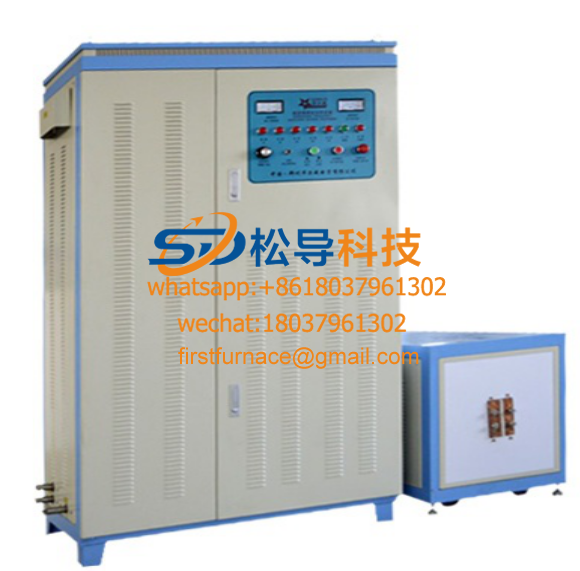

300KW high frequency induction heating equipment

300KW high frequency induction heating equipment 250kw high frequency induction heating equipment

250kw high frequency induction heating equipment 200KW high frequency induction heating equipment

200KW high frequency induction heating equipment 160kw high frequency induction heating equipment

160kw high frequency induction heating equipment 120KW high frequency induction heating equipment

120KW high frequency induction heating equipment 80kw high frequency induction heating equipment

80kw high frequency induction heating equipment 60kw high frequency induction heating equipment

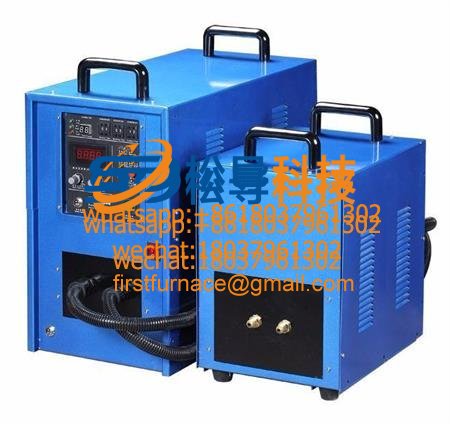

60kw high frequency induction heating equipment 50kw high frequency induction heating equipment

50kw high frequency induction heating equipment 30KW high frequency induction heating equipment

30KW high frequency induction heating equipment high frequency induction heating equipment

high frequency induction heating equipment Drill rod end high frequency heating equipment

Drill rod end high frequency heating equipment Handheld double head induction heating machine

Handheld double head induction heating machine Handheld Induction Heate

Handheld Induction Heate 16kw high frequency induction heating equipment

16kw high frequency induction heating equipment

First, the principle of induction heating?

1. The principle of induction heating of a hand-held induction heater is to generate a magnetic flux by flowing a high-frequency alternating current to a conductor (usually a copper tube) that is crimped into a ring, and the metal is placed therein, and the magnetic beam penetrates the metal body. The eddy current (rotation current) is generated in the direction in which the magnetic flux is self-contained. The induced current generates heat under the influence of the eddy current, and the heating method is induction heating.

2 , Simply put: the current generated by a metal object can be heated in a non-contact state. By using such a principle, concentrated heating is performed in a necessary place of the object to be heated to achieve an instantaneous heating effect, because this heating method has extremely high efficiency, and the throughput and the workload are improved.

Second, how to distinguish the induction heating frequency of the handheld induction heater ?

The power is selected according to power and frequency. The higher the frequency, the shallower the heating depth, and the lower the frequency, the better the heat permeability.

● High frequency range: 30 - 80 kHz ● Ultra high frequency range: 200 - 1100 kHz

● IF frequency range: 1 - 20 kHz ● Super Audio Frequency Range: 20- 50 kHz

Third, the application of induction heating power

|

-- Welding (brazing, silver welding, brazing) -- It mainly connects the two materials of the same material or different materials by heating to a certain temperature to melt the solder. The specific application is as follows: ● Welding of various hardware tools: welding of diamond tools, grinding tools, drilling tools, alloy saw blades, carbide turning tools, milling cutters, reamers, planers, woodworking drills, etc.; ● Welding of various hardware mechanical parts: hardware sanitary products, refrigeration copper fittings, lighting accessories, precision mold fittings, metal handles, egg beaters, alloy steel and steel, steel and copper, copper and copper equivalent metals or dissimilar metals Welding, brazing; ● The composite bottom welding is mainly used for the three-layer brazing of round, square and other special-shaped flat stainless steel pot bottoms and aluminum sheets, and can also be used for other metal plane brazing. ● The heating plate welding of the electric kettle (electric coffee pot) is mainly used for brazing between stainless steel flat bottom, aluminum sheet and electric heating tubes of various shapes.

|

| - Hot forging - Hot forging is mainly for the workpiece to be pressed into other shapes by pressing, forging or other forms after the workpiece is heated to a certain temperature (the heating temperature is different depending on the material). ● For example: case, watch embryo, handle, mold attachment, kitchen tableware, crafts, standard parts, fasteners, machining of mechanical parts, copper locks, rivets, steel brazing, hot extrusion of brazing tools, etc. |

| - shrink fit - The thermal fit mainly refers to the heating of the metal between different kinds of metals or between metal and non-metal, and the two are connected by the principle of thermal expansion or thermal melting. ● For example: the copper core of the computer radiator and the aluminum sheet, the buried value welding of the speaker net, the composite of the steel-plastic tube, the sealing of the aluminum foil (toothpaste skin), the rotor of the motor, the sealing of the electric heating tube and the like. |

| - Melting - Smelting it mainly refers to the metalization into a liquid by the high temperature of the metal. ● Mainly used in iron, steel, copper, aluminum, zinc and various precious metals. Such as the melting of gold and silver. |

|

-- Heat treatment (surface hardening) -- It mainly changes the hardness of the metal material by heating the workpiece, etc., and the specific application is as follows: ● Various hardware tools, hand tools.Quenching such as pliers, wrenches, hammers, axes, screwdrivers, scissors (garden shears); ● Various car and motorcycle accessories.Such as crankshaft, connecting rod, piston pin, sprocket, aluminum wheel, valve, rocker shaft, transmission half shaft, small shaft, fork, etc.; ● Various power tools.Such as gears, shafts; ● Machine tool industry category. Such as quenching of machine bed surface, machine tool guide rails, etc. ● Various hardware metal parts, machined parts. Quenching such as shafts, gears (sprocket wheels), cams, collets, clamps, etc. ● Hardware mold industry. Such as small molds, mold accessories, mold holes, etc. quenching;

|

| -- Annealing (tempering, quenching and tempering) -- Annealing is to reduce the hardness of the metal and eliminate the structural defects of the metal. ● Annealing in various stainless steel industries. Such as stainless steel pots, cans of annealing, annealing and annealing of the water tank, stainless steel tubes, stainless steel cutlery, stainless steel cups, etc.; ● Annealing of various other metal workpieces.Such as golf clubs, clubs, copper locks, hardware copper fittings, kitchen knife handles, cutting edges, aluminum pots, aluminum barrels, aluminum radiators and all kinds of aluminum products. |

How to choose a hand-held induction heater ?

Heating type | Application range | Frequency selection | Power selection |

Brazing | Drills, turning tools, reamers, milling cutters, drill bits, etc. and composite welding of different materials on stainless steel pot bottom . | Principle: The larger the welding volume, the lower the frequency should be.Tools with avolume less than 30*30*30can be used at heights; greater than30*30*30 , medium frequency can be used. Principle: The larger the diameter of the workpiece, the lower the frequency should be. | It depends on the specific workpiece shape, material, solder, etc. |

Diathermy | Fasteners, standard parts, auto parts, hardware tools, copper, twist hot upsetting hot rolling. | Φ20 or more ,medium frequency (1-20KHZ) Φ5-20, high frequency (20-100KHZ) Below Φ5 , UHF(100-500KHZ) | According to the production efficiency, choose the right power , the higher thepower, the faster the speed.Specific can consult the company's technical staff . |

Quenching | Shafts, gears, sprockets, machine tool rail accessories, quenching, etc. | Principle: The shallower the hardened layer is required for the workpiece, the higher the frequency should be. 1-2.5mm super audio 20-100KHZ Medium frequency 1-20KHZ above2.5mm ; | Combined with the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements and materials, etc., you can consult the company's technical staff. |

annealing | Metal wire pipe annealing, hydraulic fittings, auto parts, knife and pliers, stainless steel pot annealing, etc. | Combined with the requirements of workpiece annealing, annealing speed and materials, you can consult the company's technical staff. | |

Melting |

Precious metals such as gold, silver, copper and lead

| Medium frequency; small capacity optional high frequency | It depends on the furnace and production efficiency. |

welding | Aluminum-plastic pipe, steel-plastic pipe, cable, wire heating film; aluminum foil sealing used in food, beverage, pharmaceutical industry. | Depending on the circumstances | Depending on production speed, material, temperature. |

Special functions and supporting equipment | Such as dual-frequency equipment, multi-load matching type (double head, multi-tap), automatic control type, one to two, bridge oil pipeline elbow, constant power constant current, soft connection sensor. | ||

Handheld induction heater specifications

specification | Function Description |

A One-piece machine | The three processes of heating, heat preservation and cooling can be automatically converted. Heating power, thermal power, heating time, holding time, cooling time of 5 parameters can be adjusted independently. It is suitable for use in the comparison of heating temperature requirements * , such as heat treatment. |

AB Split machine | The inverter transformer is taken out separately and connected to the main unit with a flexible wire. The flexible wire is 1.5 meters. Suitable for automatic assembly lines or manual field operations for applications with poor accessibility. |

Handheld machine | Cable length: 3--50 meters long (can be customized) Refrigeration pipeline industry (copper pipe welding, joint welding). |

intelligent Integrated machine | An intelligent integrated heating machine that integrates induction power supply, chiller, PLC control and touch screen operation panel. Small size, compact structure, easy to move, easy to install and so on. Due to the advantages of energy saving and high efficiency, the heating head is light, and has been widely used in the field of copper tube welding field heating. |

Handheld induction heater technical parameters

model | LH-15KW One body /split | LH-25AB One body/split | LH-30AB Split | LH-35AB Split | LH-40AB Split | LH-60AB Split | LH-80AB Split | |

parameter | ||||||||

Input voltage | Single phase220V | 3x380V | ||||||

50 HZ /60HZ | 50 HZ /60HZ | |||||||

Output Power | 15KW | 25KW | 30KW | 35KW | 40KW | 60KW | 80KW | |

Output oscillation frequency | 30-100 KHZ | 30-80 KHZ | ||||||

Oscillationcurrent ( A) | 200-800 | 200-1200 | 200-1400 | 400-1650 | 300-1800 | 300-2100 | 300-2400 | |

Cooling water flow | >6L/min | > 7L/min | > 9L/min | |||||

heating time | 1-99 seconds (automatic state) | |||||||

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved