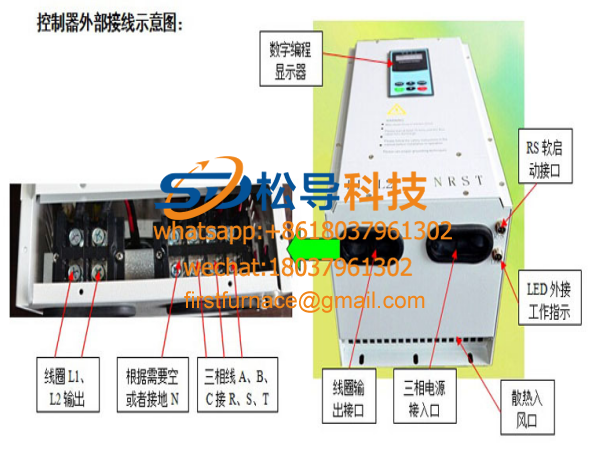

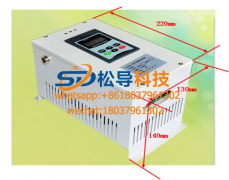

Full bridge 10KW electromagnetic heater

Full bridge 10KW electromagnetic heater Full bridge 5 KW-8KW electromagnetic heater

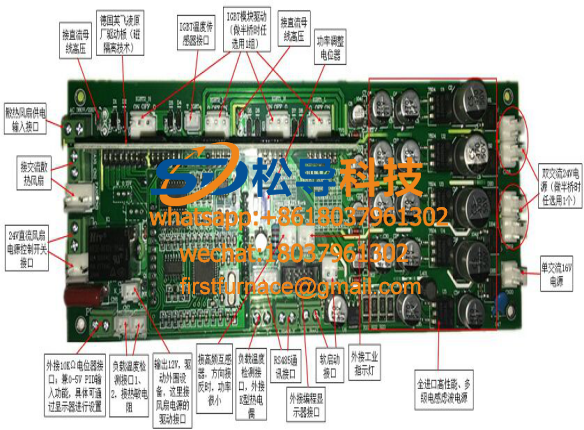

Full bridge 5 KW-8KW electromagnetic heater Electromagnetic induction heater

Electromagnetic induction heater 60KW electromagnetic induction heater

60KW electromagnetic induction heater 50KW electromagnetic induction heater

50KW electromagnetic induction heater 40KW Electromagnetic Induction Heater

40KW Electromagnetic Induction Heater 20KW electromagnetic induction heater

20KW electromagnetic induction heater 15KW electromagnetic induction heater

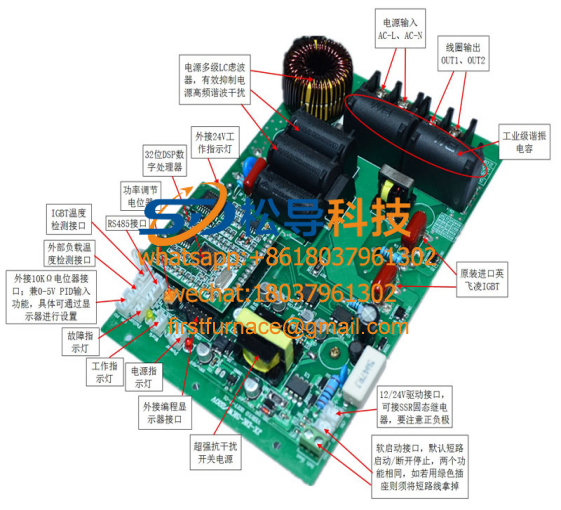

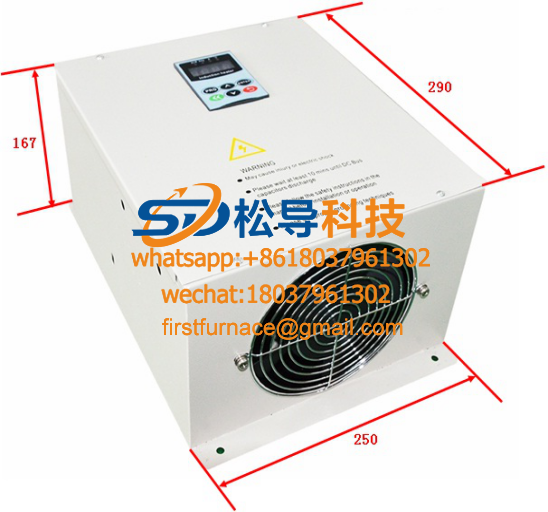

15KW electromagnetic induction heater  10KW electromagnetic induction heater

10KW electromagnetic induction heater 5KW electromagnetic induction heater

5KW electromagnetic induction heater  3KW electromagnetic induction heater

3KW electromagnetic induction heater 2.5KW electromagnetic induction heater

2.5KW electromagnetic induction heaterWhat are the applications of electromagnetic induction heaters?

Electromagnetic induction heater application industry

Electromagnetic induction heating of oil pipelines: Most of China's oil fields and oil transportation pipelines are in the north. When winter comes, the oil will flow slowly or not because of the low temperature. Therefore, in some occasions, we need to heat the oil pipeline to ensure the smooth flow of oil. . The traditional heating method uses hot water or open flame heating efficiency is not only low and has safety risks. The use of electromagnetic heating requires only one coil to solve these problems, and such devices are currently being used.

Electromagnetic induction heating in the plastics industry : The heating temperature in the plastics industry is below 500 degrees. The original mainstream heating method uses resistance heating. Because the heating method is heat conduction, the preheating time must be more than one hour, and a large amount of energy is lost during the heating process. Moreover, the temperature cannot be precisely controlled; after the electromagnetic heating is used, the way of directly heating the heating body greatly shortens the warm-up time and also reduces the heat loss, and at the same time, can accurately control the temperature and lower the temperature of the field environment. At present, electromagnetic heating of plastic equipment with relatively high power has become the mainstream heating method.

Welding preheating adopts electromagnetic induction heating : some welding parts need to be preheated to a certain temperature during welding to achieve the welding strength. The traditional heating method is mostly open flame heating and long heating time (especially some large-scale ICBC welding, such as shipbuilding) , oil drilling platform), poor heating effect, inaccurate temperature control, causing bad working conditions, etc.; and the use of electromagnetic heating can solve the above problems .

Electromagnetic induction heating furnace industry: The main use of casting, smelting, heat treatment industry. There are currently two types of electromagnetic heating equipment, medium frequency furnaces and high frequency furnaces in this field. The frequency of the intermediate frequency furnace appeared earlier (the actual use has been used ten years ago). The power of a single unit is generally several hundred kilowatts. The price is relatively expensive ( hundreds of thousands of units ) . The output current is large and the coils are mostly water-cooled by copper tubes. The high-frequency furnace was not developed until the last two years. Generally, the power of a single device is about one hundred kilowatts, and the price is tens of thousands. The output coil is mostly air-cooled and made of enameled wire. The current technology is being perfected. The biggest advantage of electromagnetic heating in these fields is that the heating is fast. For example, if a workpiece is to be quenched, the temperature of the workpiece can reach thousands of degrees by using electromagnetic equipment for a few seconds. Die casting and casting of some low melting point metals are also being replaced by electromagnetic heating.

The heat transfer oil is heated by electromagnetic induction : some equipment needs to be heated by heat transfer oil during the operation. The original heating method is heating with fossil fuel, the heating efficiency is not high and the temperature control is not accurate; after heating with electromagnetic induction heater, only need to be The heating effect can be achieved by making a coil on the pipe. The main constraint is the space problem, and some of the equipment that has space to make coils has used electromagnetic heating.

An electromagnetic induction heating roll heated: in some chemical, printing and dyeing industry, which typically requires temperatures around the drum 200 degrees Celsius. There are many ways to heat the original, and there are some drawbacks in terms of energy saving and service life. The use of electromagnetic heating only requires a coil inside the drum to uniformly heat the drum. In the past, there was a case where the drum was deformed. This technical problem has been solved.

The aluminum profile is heated by electromagnetic induction: mainly aluminum rod furnace and mold heating furnace. The mold heating furnace basically uses electromagnetic heating, and the aluminum rod furnace is still in the trial stage.

Household Induction Cooker in Civil Field: At present, the largest electromagnetic heating equipment is used. The market is mainly occupied by several major household appliance manufacturers. The performance is relatively stable, and a single-tube inverter is generally used. Dry-fried equipment: equipment for mass production of dry goods, such as fried tea machines, fried rice machines, etc. The original equipment generally burns coal, firewood, charcoal and other fuels. The main drawback is that it is difficult to mass produce, and the products produced are defective and the production environment is bad. Electromagnetic heating is gradually replacing the original with its rapid heating method and precise temperature control. device of.

Commercial Induction Cooker: Commercial Induction Cooker refers to the induction cooker used in commercial kitchens, such as restaurants, restaurants, factories, colleges, institutions, military units, enterprises and institutions, trains, ships and other commercial kitchens. It is particularly suitable for limiting the use of open flames. All commercial kitchens: basements, underground malls, railway vehicles, petrol stations, aviation, etc. The induction cooker (smoke) whose power is generally between 3 kW and 35 kW; the commercial induction cooker has the advantages of energy saving, environmental protection, safety, comfort, safety, no open flame, short heating time and fast cooking. At present, the production method provides the movement for the electromagnetic induction movement manufacturer; the kitchen factory produces its peripheral equipment. The movement with a power of 8 kW or less is a single-tube inverter, and the movement with a power of more than 8 kW is an IGBT inverter.

Advantages of electromagnetic induction heater

1 . High-efficiency, energy-saving and rapid heating adopt internal heat heating method, that is, the internal metal tube of the barrel is self-heated by electromagnetic induction, and the average preheating time is shortened by 2/3 compared with the heating method of the resistance ring , and the thermal efficiency is as high as 95% or more, and the power saving effect can reach 30. %-70% .

2 . Reduce production cost and improve product quality The heating part adopts special cable structure, which does not generate heat itself. It can withstand temperatures above 500 °C, and the service life can reach more than 5 years. There is basically no maintenance cost in the later period. Because electromagnetic heating is to automatically heat the barrel through electromagnetic induction, the heat utilization rate is up to 95% , which can fully and uniformly heat the raw materials, thereby improving product quality.

3 . The reliable and controllable adjustable host adopts the most advanced industrial machine board, micro-electronic control, multi-channel intelligent closed-loop system and perfect protection function, which effectively avoids the aging phenomenon of the host and fully guarantees the long-term safe and stable operation of the equipment. .

4 . Improve the working environment The surface temperature of the equipment is touched by the human body, which greatly improves the working environment at the production site, effectively improves the production enthusiasm of the workers and reduces the cost of traditional cooling facilities. In the "people-oriented" concept, create a more green, energy-saving, safe and comfortable production environment.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved