Rolling mill detailed introduction

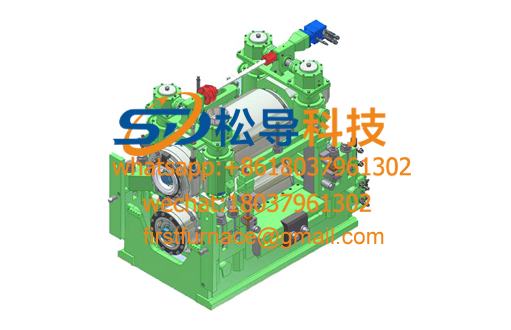

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

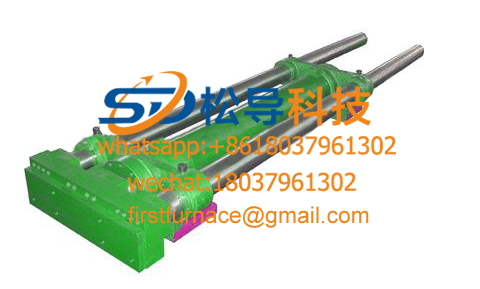

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production lineIt mainly produces rolling mills, cold rolling mills, hot rolling mills, aluminum foil rolling mills, four-roll mills, rolling mill parts and ball mills. We provide free installation, commissioning and training of technicians and other related services. Users are welcome to come to consult and negotiate.

1. Overview of steel production line

Steel is a straight solid steel that has been plastically shaped and has a certain cross-sectional shape and size. It is also called a profile and a long material.

H- beam is a common structural form of beams and columns in petrochemical plants and building frame structures. Conventional production of 'steel' is mainly manual operation, low degree of automation, high labor intensity, high production cost, unsatisfactory efficiency, and large welding deformation. Product quality is difficult to guarantee. In the current oilfield, the production method of 'type steel structure such as the floating beam of the pumping unit and the steel column of the factory building is basically using the “anti-deformation method”, the production cost is high, the hydraulic press is required to carry out the pre-fabrication and deformation, and the production efficiency is not high, although the welding is adopted. The automatic submerged arc welding process, but the welding deformation is still difficult to eliminate. Here, we introduce a 'steel steel production line consisting of four main equipments:multi-head gas cutting machine, steel forming machine, steel door submerged arc welding machine and steel wing wing straightening machine . The production line can greatly improve the automation degree of steel production. , reduce labor intensity and production cost, improve economic efficiency, and can easily correct welding deformation, thereby improving product quality.

2 , H- beam production line equipment equipment structure, process, layout method .

The steel production line is mainly composed of four main equipments: multi-head cutting machine, steel forming machine, steel door submerged arc welding machine and steel flange correction machine . The multi-head cutting machine is a 3000A- multi-head linear gas cutting machine. It is a rate flame cutting device equipped with ($ group torch) for cutting in the longitudinal and transverse directions. The technical parameters of the multi-head cutting machine are: gauge distance 1000mm , rail Length 14400mm ( can be lengthened according to actual production conditions ) , cutting speed 100-750mm/min , cutting width 80-2300mm, longitudinal cutting torch 9 sets, transverse cutting torch 1 group. The new gas burns in oxygen at a temperature of 3204-3315 degrees Celsius, In the air, the ignition point is 510-580 °C, the ignition point in oxygen is 490-570 °C, the total heating value after gasification is 53.1kj/g , and the burning rate in oxygen is 3.28m/s, which is in line with the policy of saving energy, protecting the environment and safety. It has the characteristics of health and hygiene, good cutting quality, low cost and high speed.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved