300KW high frequency induction heating equipment

300KW high frequency induction heating equipment 250kw high frequency induction heating equipment

250kw high frequency induction heating equipment 200KW high frequency induction heating equipment

200KW high frequency induction heating equipment 160kw high frequency induction heating equipment

160kw high frequency induction heating equipment 120KW high frequency induction heating equipment

120KW high frequency induction heating equipment 80kw high frequency induction heating equipment

80kw high frequency induction heating equipment 60kw high frequency induction heating equipment

60kw high frequency induction heating equipment 50kw high frequency induction heating equipment

50kw high frequency induction heating equipment 30KW high frequency induction heating equipment

30KW high frequency induction heating equipment high frequency induction heating equipment

high frequency induction heating equipment Drill rod end high frequency heating equipment

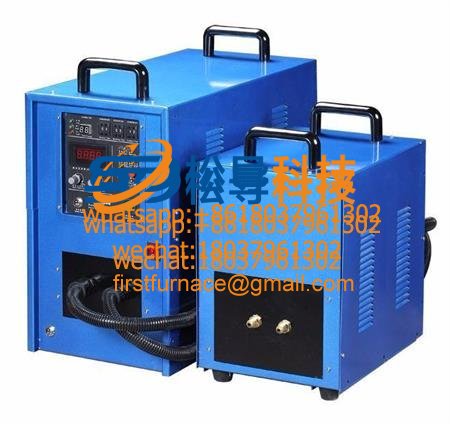

Drill rod end high frequency heating equipment Handheld double head induction heating machine

Handheld double head induction heating machine Handheld Induction Heate

Handheld Induction Heate 16kw high frequency induction heating equipment

16kw high frequency induction heating equipment

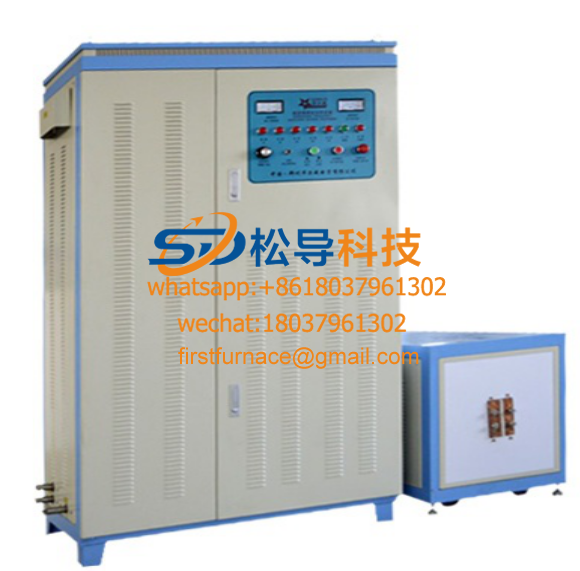

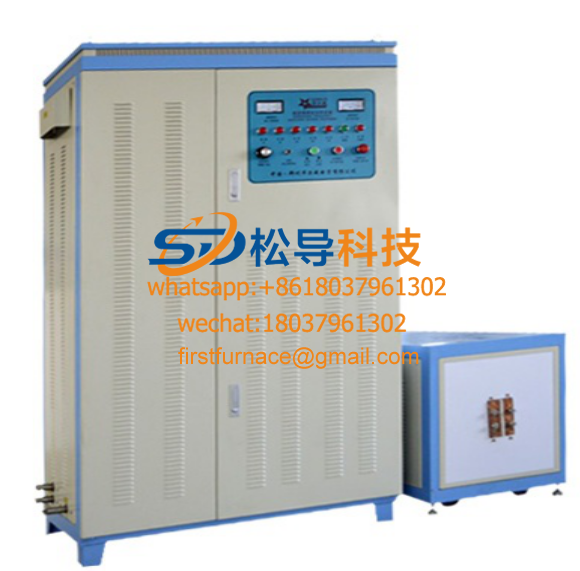

Model: SD-250

Input power: 250KW

Input voltage: 360V ~ 420V

Oscillation frequency: 15 ~ 35KHz

Application areas:

1. Heating forging of round steel with a diameter of 50mm or less.

2 , Φ 500mm discs, Φ 350mm shaft quenching.

3. The machine guide rail is quenched.

4 , quenching treatment of auto parts and motorcycle parts.

5 , heat treatment of workpieces such as pliers, wrenches, screwdrivers, hammers, axes, etc.

The split design is suitable for use in a variety of different environments. It consists of a rectification part, a filtering part, an inverter part, a main control part, a driving part, a transformer unit, etc., and is fully protected.

250kw high frequency induction heating equipment technical parameters selection:

Working power | Three-phase380V/50Hz | Cooling water flow (host) | 32L/Min ( 0.1MPa ) |

Operating voltage range | 360V ~ 420V | Cooling water flow (transformer) | 29L/Min ( 0.1MPa ) |

Input Current | 380A | Cooling water pressure | 0.1 to 0.3 MPa |

Output Power | 250KW | Host weight | 225Kg |

Oscillating frequency | 15 ~ 35KHz | Transformer weight | 115Kg |

Transformer dimensions (mm3 ) | 500 × 600 ×1000 | Mainframe dimensions ( mm3 ) | 530 × 1000 × 1850 |

Features:

1. IGBT is used as the main device and full-bridge inverter, with perfect protection function and high reliability.

2 , remote control and matching infrared temperature measurement, automatic temperature control, improve heating quality and simplify worker operation.

3 , replace the oxy-acetylene flame, coke oven, salt bath furnace, gas furnace, oil furnace and other heating methods.

4 , using frequency automatic tracking and multi-channel closed-loop control, easy to install, easy to operate.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved