Copper melting furnace

Copper melting furnace 800kg electromagnetic copper melting furnace

800kg electromagnetic copper melting furnace 600KG electromagnetic copper melting furnace

600KG electromagnetic copper melting furnace 500KG electromagnetic copper melting furnace

500KG electromagnetic copper melting furnace 400KG electromagnetic copper melting furnace

400KG electromagnetic copper melting furnace 350KG electromagnetic copper melting furnace

350KG electromagnetic copper melting furnace 300KG electromagnetic copper melting furnace

300KG electromagnetic copper melting furnace 250KG electromagnetic copper melting furnace

250KG electromagnetic copper melting furnace 200KG electromagnetic copper melting furnace

200KG electromagnetic copper melting furnace 200KG medium frequency copper melting furnace

200KG medium frequency copper melting furnace 100kg electromagnetic copper melting furnace

100kg electromagnetic copper melting furnace 50KG medium frequency copper melting furnace

50KG medium frequency copper melting furnace Medium frequency copper melting furnace

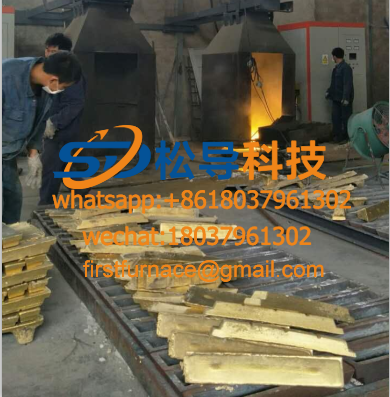

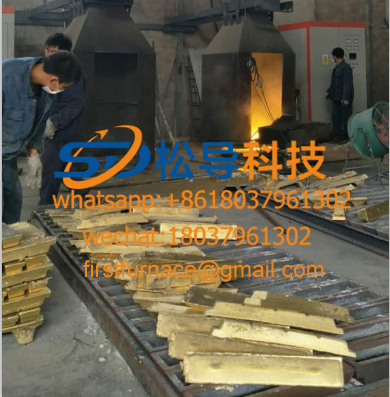

Medium frequency copper melting furnace Scrap copper melting furnace

Scrap copper melting furnace Copper melting furnace

Copper melting furnaceCopper melting furnace

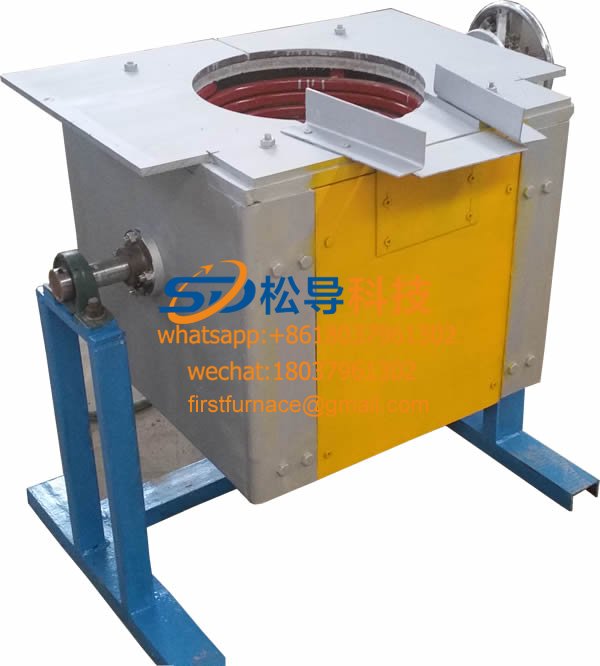

Copper melting furnace, induction copper melting furnace, means that the molten metal is copper, which is also a kind of induction melting furnace , Intermediate frequency power supply 100- 2500KW .

1. The working principle of the copper melting furnace : It is a power supply device that converts 50HZ power frequency alternating current into intermediate frequency ( above 300HZ to 1000HZ ). The adjusted intermediate frequency current supplies the intermediate frequency alternating current flowing through the capacitor and the induction coil, which generates high-density magnetic lines of force in the induction coil, and cuts the metal material contained in the induction coil, resulting in a large eddy current in the metal material . Use the principle of electromagnetic induction to heat metal.

Second, the commonly used model selection of copper melting furnace:

model | parameter name | ||||

Rated capacity | Rated power | Working temperature | Melting rate | Frequency | |

GWJTZ0.3-160-1 | 0.3 | 160 | 1200 | 0.3 | 1000 |

GWJTZ0.5-250-1 | 0.6 | 250 | 1200 | 0.495 | 1000 |

GWJTZ1.0-500-0.5 | 1.0 | 500 | 1200 | 1.0 | 1000 |

GWJTZ1.5-750-0.5 | 1.5 | 750 | 1200 | 1.678 | 1000 |

GWJTZ3-1500-0.5 | 3.0 | 1500 | 1200 | 3.650 | 1000 |

GWJTZ8-3000-0.4 | 8.0 | 3000 | 1200 | 6 | 1000 |

3. How to choose the frequency and power of the copper melting furnace ?

The smelting of copper metal materials, the smelting volume is 0.05T-5T , and the efficiency is high. It has electromagnetic stirring power to make the metal smelt uniformly without adding other stirring procedures. According to the different output frequency, it can be roughly divided into: ultra high frequency, high frequency, super audio frequency, intermediate frequency and so on. Different heating processes require different frequencies. If the frequency is selected incorrectly, the heating requirements cannot be met, such as slow heating time, low work efficiency, uneven heating, temperature failure, and even damage to the workpiece. After you have determined the frequency of the machine according to the requirements of your workpiece, the next step is to select the appropriate machine power according to the production situation. The greater the power of the machine, the faster its heating speed, but its price will increase accordingly. The low-power equipment has low cost and its heating speed is slow.

Fourth, what are the advantages of the copper melting furnace ?

1. Ultra-small size, movable, covering an area of only 0.6 square meters.

2. It is convenient to replace the furnace body of different weight, different material, and different starting method to meet various melting requirements;

3. It is very convenient to install, debug and operate, and you will know it as soon as you learn;

4. It can work uninterrupted for 24 hours, and the smelting is even and faster;

5. Environmental protection, in line with environmental protection requirements, eliminating the trouble of environmental protection inspection;

6. Energy saving, compared with the thyristor intermediate frequency, not only is it small in size and easy to maintain, it can also save 15-20% of electricity .

7. With electromagnetic stirring effect, it is conducive to the uniformity of smelting metal temperature and structure, is conducive to scum and reduces impurities;

8. The equipment is small in size and light in weight. The melting capacity ranges from a few kilograms to hundreds of kilograms, with a wide range of options. It is not only suitable for factory production and use, but also suitable for small-scale smelting in schools and research institutes;

5. What problems should be paid attention to during copper alloy smelting ?

1. Do not take samples on the surface of copper liquid for performance test . Copper alloys are easy to oxidize and get gas, and the slag and gas content on the liquid surface is significantly higher than that of the lower copper liquid ; therefore, the performance test done by sampling the copper liquid surface is not accurate. For correct sampling, after fully stirring the copper liquid, use a sampling spoon to scoop up the molten metal from the bottom of the crucible.

2. The time of smelting should be controlled . The time from the start of melting to the end of melting is called the melting time. The length of the melting time not only affects the productivity, but also obviously affects the quality of the cast parts. The increase of the melting time will increase the element burning rate of the alloy and increase the chance of inhalation. Therefore, the melting work should be completed in the shortest time. When permitted, try to increase the preheating temperature of the charge, the operation should be compact, and the action should be rapid.

3. The stirring rod used for smelting should be a carbon rod. If other stirring materials such as iron rods are used, the iron rods will melt during the stirring process, which will affect the chemical composition of the alloy. At the same time, if the preheating temperature of the iron rod in the furnace is relatively high or the stirring time is longer, the oxides on the iron rod will enter the alloy liquid and become impurities ; if the preheating temperature of the iron rod is low, the alloy will be stirred during stirring. It must be attached to the iron rod, which can be observed in production.

4. The use of covering agent during smelting. For smelting copper alloys, the amount of covering agent is generally : 0.8%-1.2% of the weight of the charge when using glass and borax , because the thickness of the covering layer is 10-15mm; When using charcoal, the dosage is 0.5%-.0.7% of the weight of the charge . To maintain the thickness of the covering layer of 25-35mm, the stripping of the covering agent is generally carried out before pouring. Too early will increase the oxidation and suction of the copper alloy. If charcoal is used as the covering agent and the slag blocking effect is good, the covering agent may not be stripped off, so that it also plays a role of blocking the slag during the pouring process, and the effect is more ideal.

Sixth, melting copper furnace of a graphite crucible how to choose?

Copper melting graphite crucible / silicon carbide crucible smelting various gold, silver, copper, aluminum, lead, zinc and other non-ferrous metals, medium carbon steel, various rare metals and carbon products manufacturing. It is suitable for metal smelting in underground furnaces, electric furnaces, intermediate frequency furnaces and high frequency furnaces.

1. Good high temperature resistance of molten copper graphite crucible, the melting temperature can be as high as about 1800 ° C ;

2. Good thermal conductivity of graphite crucible for molten copper has a small thermal expansion coefficient, can conduct heat quickly, and has strong strain resistance to rapid heating and quenching;

3. The excellent chemical stability of the special crucible for melting copper has strong corrosion resistance to acid and alkaline solutions.

PREV:800kg electromagnetic copper melting furnace

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved