300KW high frequency induction heating equipment

300KW high frequency induction heating equipment 250kw high frequency induction heating equipment

250kw high frequency induction heating equipment 200KW high frequency induction heating equipment

200KW high frequency induction heating equipment 160kw high frequency induction heating equipment

160kw high frequency induction heating equipment 120KW high frequency induction heating equipment

120KW high frequency induction heating equipment 80kw high frequency induction heating equipment

80kw high frequency induction heating equipment 60kw high frequency induction heating equipment

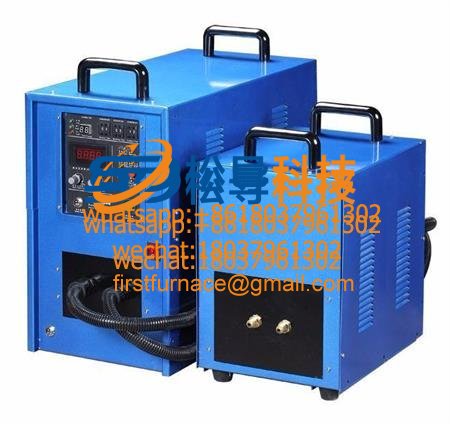

60kw high frequency induction heating equipment 50kw high frequency induction heating equipment

50kw high frequency induction heating equipment 30KW high frequency induction heating equipment

30KW high frequency induction heating equipment high frequency induction heating equipment

high frequency induction heating equipment Drill rod end high frequency heating equipment

Drill rod end high frequency heating equipment Handheld double head induction heating machine

Handheld double head induction heating machine Handheld Induction Heate

Handheld Induction Heate 16kw high frequency induction heating equipment

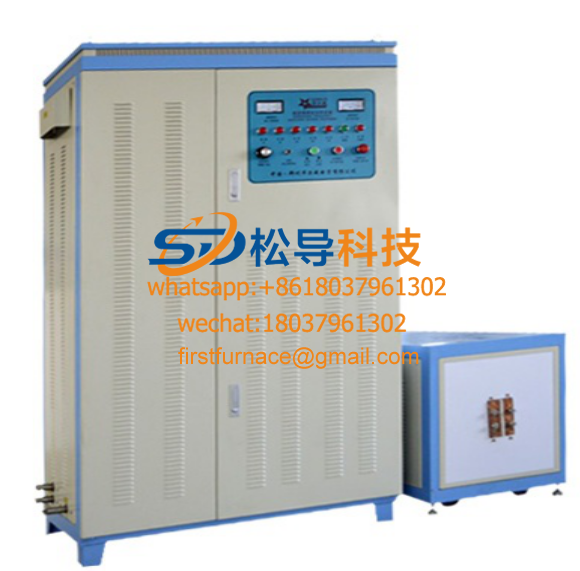

16kw high frequency induction heating equipmentModel: SD-300

Input power: 300KW

Input voltage: three-phase 380V/50Hz

Oscillation frequency: 15 ~ 35KHz

Application areas:

1. Heating forging of round steel with a diameter of 50mm or less.

2 , Φ 600mm discs, Φ 400mm or less shaft quenching.

3. The machine guide rail is quenched.

4 , quenching treatment of auto parts and motorcycle parts.

5 , heat treatment of workpieces such as pliers, wrenches, screwdrivers, hammers, axes, etc.

The split design is suitable for use in a variety of different environments. It consists of a rectification part, a filtering part, an inverter part, a main control part, a driving part, a transformer unit, etc., and is fully protected.

Selection of technical parameters of 300kw high frequency induction heating equipment :

Working power | Three-phase380V/50Hz | Cooling water flow (host) | 32L/Min ( 0.1MPa ) |

Operating voltage range | 360V ~ 420V | Cooling water flow (transformer) | 29L/Min ( 0.1MPa ) |

Input Current | 450A | Cooling water pressure | 0.1 to 0.3 MPa |

Output Power | 300KW | Host weight | 235Kg |

Oscillating frequency | 15 ~ 35KHz | Transformer weight | 125Kg |

Transformer dimensions (mm3 ) | 500 × 600 ×1000 | Mainframe dimensions ( mm3 ) | 530 × 1000 × 1850 |

300kw high frequency induction heating equipment features:

1. IGBT is used as the main device and full-bridge inverter, with perfect protection function and high reliability.

2 , remote control and matching infrared temperature measurement, automatic temperature control, improve heating quality and simplify worker operation.

3 , replace the oxy-acetylene flame, coke oven, salt bath furnace, gas furnace, oil furnace and other heating methods.

4 , using frequency automatic tracking and multi-channel closed-loop control, easy to install, easy to operate.

How to choose 300kw high frequency induction heating equipment ?

1, temperature control, welding class 15kHz frequency induction heating device, a heatable work of φ 80, the welding can be more cemented carbide cutting tools

Standard parts, the enthusiasm of the fasteners.

Brazing, heating of tempering, forging, extrusion, etc. of the drill.

Welding of diamond saw blades and drills.

Welding of bits, coal bits, riveting bits and picks.

Welding of turning tools, planers, milling cutters and various woodworking tools.

2 , the frequency of quenching high-frequency induction heating equipment is about 40KHZ , the small one can quench φ 10 high-precision small shaft, the hardened layer is kept within 1mm , the larger one can be φ 250 diameter large shaft, and can also quench φ 500 or so gear.

Quenching treatment of auto parts and motorcycle parts. Heat treatment of mechanical parts.

Such as quenching treatment of various gears, sprockets, various shafts, spline shafts, pins, and the like.

Quenching of machine tool guide rails in the machine tool industry.

Heat treatment of pliers, wrenches, screwdrivers, hammers, axes, etc.

3 , annealing high frequency induction heating equipment

Various mechanical parts can be annealed in one piece or in part.

The φ 300 diameter stainless steel container can be subjected to tensile annealing.

Misunderstanding 1: only look at power, do not look at frequency

When standard parts, fasteners, etc. heating when the heating of the workpiece diameter is greater than 80mm, IF equipment should be selected, while still resulting in the workpiece outside "burn flow" inside the high frequency opportunity "black" (commonly known as "burn-impermeable "), not only the equipment efficiency is greatly reduced, but also reduce the mold life or even cause mold damage, invisible cost increase, but I do not know the reason.

Misunderstanding 2: just look at the output, do not look at the input

Ignore the efficiency of the equipment and the power consumption factor. After the equipment was purchased, it was discovered that it was an "electric tiger", which made it affordable and could not afford the embarrassing situation. For example, the same 80 machine, but an input power is 80kw , but the equipment work efficiency is very different, although the heating requirements can be completed, but the power consumption makes Yonghe complain not to fall. The output power of the device outputting 80lw is as high as 120kVA .

Misunderstanding 3: only look at the model, do not look at the power

For example, the equipment input current 120A and input power 120KVA are mixed together, collectively referred to as 120 machines, so that after the purchase, the real power is only 80KVA , which is obviously cheap, but it is a loss.

With the continuous development of industry, the continuous improvement of induction heating technology, the application of high frequency induction heating equipment is more and more extensive. When selecting the type, you must look for the national standard product, and you can't choose it because of the low price or the saving of the map.

PREV:250kw high frequency induction heating equipment

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved