What are the methods for tempering quenched parts of induction heating furnace ?

The main purpose of induction heating furnace quenching workpiece tempering is to reduce the quenching stress and avoid quenching cracks; sometimes, tempering is to reduce the hardness to meet the technical requirements of the workpiece.

There are roughly three ways to temper a workpiece after quenching in an induction heating furnace :

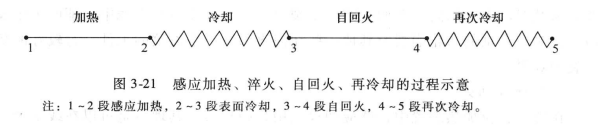

(1) When the self-tempering workpiece is quenched, the cooling does not proceed to the end and is interrupted in advance, so that the residual heat adjacent to the core of the hardened layer is transferred to the hardened layer, so that the hardened layer is heated again to reach a certain tempering temperature. Make the hardened layer get the required structure and performance. This method was used for the quenching of tool chisels and steel rails in the early days.

In the former Soviet Union early 20 century, 50 years, began to be used induction furnace hardened workpieces, such as crank journal, a gear, a number of pins and other auto parts, the process may be used in FIG. 3-21 to FIG.

In some self-tempering processes, stages 4 to 5 are cooled by spraying water again, while in most self-tempering, stages 4 to 5 allow the workpiece to cool naturally in the air.

The advantage of the self-tempering process is that it saves a set of tempering equipment. Take the crankshaft journal quenching as an example. Due to the adoption of this process in an automobile manufacturing plant, a tempering furnace with a power of 100kW and a production area of 30m 2 are saved on the production line . In addition, it saves electricity and maintenance costs. However, the self-tempering process also has shortcomings, so its application is limited.

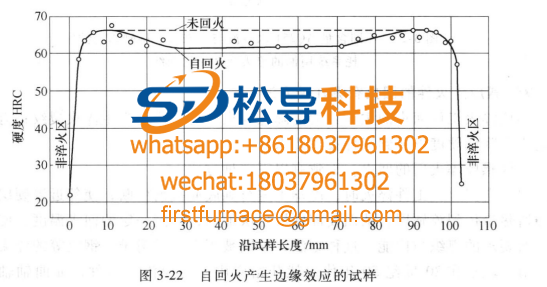

1 ) The self-tempering process is only suitable for workpieces with sufficient residual heat in the core of the workpiece after heating, and the residual heat transfer to all points of the hardened layer should be uniform; otherwise, the hardness of the quenched surface of the workpiece is inconsistent after self-tempering , And even individual areas are not self-tempered. For example, after a single heating and quenching of an automobile flywheel ring gear, 48-56HRC is required. Self-tempering is used to achieve good results. The self-tempering temperature of each part of the gear ring is uniform. However, when the crankshaft journal is quenched, the so-called edge effect appears on the middle main journal and the main journal on the flange side, that is, the self-tempering temperature of the middle section of the journal is high; and the transition area on both sides is close to the crank. It heats metal and dissipates heat quickly, and the self-tempering temperature is low. Therefore, the hardness of the middle section of the entire section is relatively low, while the hardness of the transition sections on both sides is relatively high. This section is the tensile stress zone and is the most prone to quenching cracks.

The edge effect can be illustrated in Figure 3-22 . The self-tempering effect in the middle section of the sample is good, and the effect on both sides is poor, resulting in a hardness difference of about 5HRC . Tests have proved that self-tempering is suitable for heating workpieces with large diameter and large heat capacity, that is, d>m, with high thermal efficiency. It is not suitable for heat conduction heating methods and workpieces with small diameter and too small core heat.

2 ) Another major advantage of the self-tempering process is its timeliness. As we all know, induction heating furnace quenching workpieces generally requires timely tempering to prevent cracks before tempering. In the production practice of self-tempering, it is proved that due to timely tempering, it has a better effect of preventing cracking of the cam of the camshaft and other workpieces that are prone to cracks before tempering. "

(2) Tempering of induction heating furnace

In modern induction heating furnace heating devices, the application of induction heating furnace tempering is expanding day by day. The reason is that it can be produced on-line, shorten the production cycle, and make up for some difficulties that cannot be solved by self-tempering.

Induction heating furnace tempering is simple, can be produced on-line, and solves the disadvantages of self-tempering, such as edge effect, and is used in modern production. There are generally two ways to temper an induction heating furnace :

1) using the original quench heating power supply, the original induction heating furnace, the device is equipped with a way to reduce power induction heating furnace tempering. The advantage of this method is that the quenching and tempering process is completed in one loading and unloading, but because the quenching station is occupied, the productivity is reduced.

This process is applied to these small parts such as motorcycle cranks. After half-axis scanning hardening, 1/5 to 1/6 of the intermediate frequency voltage of the quenching process with the same inductor was used for tempering in a scanning induction heating furnace . The disadvantage is that the original quenching heating power supply is used in the tempering low temperature condition, and its current frequency must be higher than the normal frequency. Therefore, the tempering of the hardened layer depends entirely on heat conduction, and its thermal efficiency is low.

2) Use another set of suitable lower frequency power supply and inductor for tempering, and this method is widely used now. Because the tempering temperature of induction heating furnace quenched parts is lower than the Curie point, and most of them are lower than 300 ℃ , at this time, the current penetration depth at low temperature is often 1/10 of the current penetration depth at 800 ℃ ~ 1/4 . Therefore, the current frequency selected for tempering the workpiece is much lower than the current frequency during quenching and heating. It is customary to use 1000 ~ 4000Hz, and some directly use power frequency, such as cylinder liners and flywheel ring gears.

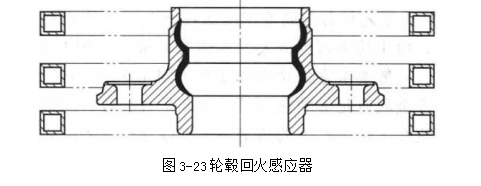

Tempering inductors generally use multiple turns, the gap between the effective ring and the workpiece is enlarged, and the area of the tempered part is often larger than the quenched area. Hub tempering sensor , as shown in Figure 3.23 .

When the semi-shaft adopts the scanning quenching process, its tempering is also tempered by an induction heating furnace . At this time, another lower frequency power source is used and a multi-turn inductor is used for heating and tempering once.

3 ) Advantages of induction heating furnace tempering:

① Short heating time, high productivity, induction heating furnace low temperature tempering heating rate is 4~2 (H : /s, medium and high temperature tempering heating rate is 5~30Y/s, cylinder liner uses power frequency tempering, 3 pieces at a time , 220 ℃ Tempering time is 30 ~ 40s .

② Stable and better mechanical properties can be obtained.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved