Rolling mill detailed introduction

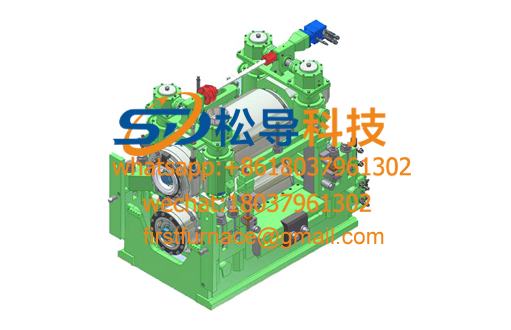

Rolling mill detailed introduction Steel production line detailed introduction

Steel production line detailed introduction Universal mill detailed introduction

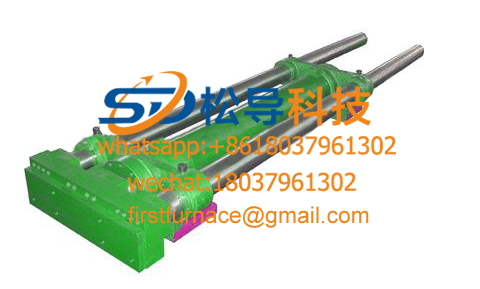

Universal mill detailed introduction Pusher detailing

Pusher detailing Four-roll mill detailed introduction

Four-roll mill detailed introduction Three-roll mill detailed introduction

Three-roll mill detailed introduction Hot rolling mill detailed introduction

Hot rolling mill detailed introduction Aluminum casting mill details

Aluminum casting mill details Aluminum magnesium silicon alloy rod continuous casting and r

Aluminum magnesium silicon alloy rod continuous casting and r Six-roll cold rolling mill

Six-roll cold rolling mill Continuous rolling mill

Continuous rolling mill Cold rolled rebar equipment details

Cold rolled rebar equipment details Detailed introduction of cold rolling steel

Detailed introduction of cold rolling steel Straightening machine details

Straightening machine details Roller table, lifting table details

Roller table, lifting table details Billet fixture

Billet fixture Two-roll cold rolling mill

Two-roll cold rolling mill Short stress rolling mill detailed introduction

Short stress rolling mill detailed introduction Fixed-length cutting machine detailed introduction

Fixed-length cutting machine detailed introduction strip production line

strip production line1, to realize rolling mill with three rolls, the larger diameter upper and lower rollers, to help drive the motor, the smaller diameter rollers, upper and lower rollers by the frictional transmission. The direction of rotation of the rolls is constant, passing between the lower roll and the middle roll in one direction, and the return is passing between the middle roll and the upper roll. In order to lift the rolled piece and feed it into the roll, a lifting table is required. The three-roller-type rolling mill uses an AC induction motor to drive the flywheel reducer. Therefore, the capacity of the assist motor can be reduced. Its medium roll diameter is small, the rolling pressure can be reduced, and the middle roll is supported by the upper and lower rolls, so the rigidity is increased. In addition, the middle roller is easy to replace, and the rest is convenient, and the control roll type is easily realized, so that the thickness precision of the product is improved compared with the two-roll type.

The disadvantage is that; the shift is not due, the small diameter rollers, idler rollers and because it is greatly reduced biting ability. In addition, the three-roll mill has a complicated structure and maintenance.

2 , the working principle of the three-roll mill :

Several stands of the continuous rolling mill are arranged in a row in the order of rolling direction. The rolled pieces are deformed by milk in several stands at the same time. The rolling speed of each frame increases with the increase of the length of the rolled piece, and the metal is preserved every time. The second flow in the mill is equal or has a slight stacking steel relationship. This type of mill is a modern rolling mill with high productivity. Such rolling mills are often used in slab rolling mills, wide strip hot rolling mills, small rolling mills, wire rod mills, and cold-rolled strip mills.

Features of the continuous mill:

1. The continuous rolling mill is highly mechanized and automated;

2. The finished product of the continuous mill has a high emulsion speed. For example, the export speed of the non-twisted continuous wire mill has reached 130m/s .

3. About semi-continuous rolling mills:

The semi-continuous mill consists of a horizontal unit and a continuous unit. The initial rolling mill of the early semi-continuous rolling mill was a continuous rolling mill, and the middle and finishing rolling mills were a horizontal rolling mill. The improved semi-continuous rolling mill is a double-rolling mill. The roughing mill can be a horizontal, continuous or tracking mill. The medium and finishing mills are double-roll mills.

3. What pressure rolling process rolling, rolling mill is?

Generally, the rolling process of a single-stand twenty-roll cold rolling mill can be divided into feeding and wearing, reversible rolling; unloading and rewinding 3 steps

segment. The twenty-roll mill, especially the Sendzimir twenty-roll mill, is rolled with large tension; the rolling process is from steel

The belt starts only after the tension is applied by the coiler / unwinder before and after the rolling mill , which is the loading and wearing stage.

Feeding and wearing stage: Generally, the steel roll is sent to the unwinder roll by the feeding trolley; the floating unwinding machine is mostly used for the unwinding.

To ensure that the steel strip is always in the center of the rolling mill; the floating uncoiler is controlled by a universal hydraulic cylinder of the photoelectric centering device;

The rolled steel strip is straightened by a straightening machine ( three-roll straight or five-roll straightening machine ) ; some rolling mills are equipped with hydraulic shears for cutting heads; steel strips are used with upper swinging guides across the machine front coiler , directly to the twenty high mill; uncoiler then continue to move the steel strip through the roll has been fed to the machine after the coiling jaws, the jaws clamp the lead strip and wound on a reel 2 - 3 laps Stop the belt and end the belt.

Reversible rolling stage : After the end of the belt, first place the upper and lower work rolls ( when the belt is worn, the work rolls have been removed ) , then adjust the rolling line, close the rolling mill closing door, press the front platen, the outlet side The wiper presses the steel strip, the rolling mill process lubrication cooling system starts the liquid supply, the rolling mill belt is pressed down, the coiler rotates to give the steel belt front tension, the machine before and after the thickness gauge and the speedometer enter the rolling line, and the unit operation starts first. Rolling of the pass.

During the rolling process, if it is found that the defect of the edge of the steel strip will affect the high speed rolling, when the defect part passes through the roll;

The operator presses the button on the console to input its defect position signal into the AGC system. At the end of the rolling, the rolling mill is decelerated. When the tail of the steel strip reaches the position of the front winder, the unit stops and the first pass ends. Thickness gauge, speedometer exit rolling

The line is rolled up, the tension of the steel strip is released, the cooling lubricant is stopped, and the pressure plate is lifted.

In the second rolling, the steel strips move in the opposite direction, and the positions in front of the machine are interchanged. After the second pass starts, the coiler is reversed.

To the front of the machine, the head of the steel strip is sent to the front of the reeling machine, and the jaws of the machine are clamped.

Winding 2 - 3 turns on the reel ; then, the rolling mill supplies cooling lubricant, the rolling mill is pressed, and the machine is driven by the front and rear coiler

Tension, the machine before and after the thickness gauge and speedometer enter the rolling line, and the unit starts rolling in the second pass.

Starting from the second pass, the rolling is carried out between the front and rear coiler and the twenty-roll mill. Fully automatic control is achieved when the mill's automatic thickness control (ACC) system is put into operation. When the steel has a defect in the rolling process, the rolling machine automatically decelerates. At the end of the rolling, the rolling mill will automatically stop.

Generally, the reversible rolling mill rolls an odd number of passes, but when the front and rear coiler is an expansion and contraction reel, the even track can be rolled.

The roll can also be unloaded on the side of the mill unwinder. Generally, before the finished pass rolling, the work rolls need to be replaced to obtain the surface quality of the steel strip with high quality and special requirements. After the finished pass rolling, the rolling mill stops, presses and picks up, the thickness gauge and the speedometer exit the rolling line, the rolling mill stops cooling the lubricating fluid supply, the coiler of the coiler is pressed down, or the unloading trolley is raised. The small seat roller is pressed against the steel coil to prevent the steel coil unwinding machine from rotating and winding the tail of the steel strip onto the reel. The reversible rolling process is now complete.

Unloading and rewinding stages : For expansion and contraction reel take-up machines, unloading is relatively simple. First use the straps in the radial bundle of steel coils

When the tie is unfolded, the unloading trolley is raised to withstand the steel coil, the reeling machine reel is contracted, the jaws are opened, the steel coil is held by the unloading trolley, and the unloading trolley and the auxiliary pusher of the reeling machine are synchronously moved. The coil is unloaded from the coiler and the unloading trolley continues to move to transport the coil to the coil storage station.

For coilers with solid rolls before and after the mill, the coil cannot be removed directly from the drum, only the coil is re-rolled

The steel coil can be removed by going to a expansion and contraction reel. When the Sendzimir 20-roll mill and the Sendway 20-roll mill use a solid reel coiler, the unit is generally equipped with a rewinding mechanism to transfer the finished steel coil and the solid reel together from the take-up position to the rewinding unwinding. Position i then rewinds the coil from the uncoiler to the rewinding machine. Since the rewinding process is carried out at a location outside the rolling zone of the rolling mill, rewinding and rolling can be carried out simultaneously without affecting each other.

Rolling process

1 depressed system

The rolling mill rolling system should be based on the technical parameters of the rolling mill, the mechanical properties of the rolled material, and the quality requirements of the product.

At the same time, we must also consider the high production capacity of the rolling mill and the low consumption. Rolling high-quality carbon steel with a twenty-high mill is relatively easy. The purpose of using a twenty-roll mill is to pursue

The high quality of the product, with high dimensional accuracy, shape and surface quality, results in a thinner product.

Carbon steel, especially low-carbon soft steel, can achieve a total reduction ratio of more than 95 % in one rolling pass and a pass reduction rate of 66 % in a 20-roll mill .

For reversible cold rolling mill, since each pass is the same - the rolling mill stand, the rolling reduction passes with equal pressure distribution is determined principles rolling reduction procedures. Generally, the second pass of the first pass has the largest reduction rate, and the hardening of the steel strip is hard.

The pass reduction rate is gradually reduced so that the rolling pressures of the passes are substantially equal.

In order to improve the production capacity of the rolling mill, under the premise of making full use of the main drive power of the rolling mill and the front and rear coiler,

It is possible to increase the rolling reduction rate to reduce the rolling pass. However, sometimes in order to obtain good shape and surface quality, reduce

The thickness deviation of the longitudinal direction of the steel strip can also be appropriately increased by the rolling pass. When the total rolling reduction ratio is the same, the use of more rolling passes can slightly increase the strength of the steel strip. The reduction rate of the finished pass has a great influence on the shape of the plate, generally 10 %.

about.

2 tension system

One feature of cold-rolled steel strips is tension rolling; cold rolling of steel strips is not possible without tension. Tension can reduce rolling

Pressure, improve shape, and stabilize the rolling process. The tension system is very important for cold rolling of steel strips.

The ten-roll mill ( and multi-roll mill ) which is rolled by small-diameter work rolls , the process characteristics of the rolling process are large

Tension rolling.

Large unit tension must be used due to the physical-mechanical anisotropy of the material being rolled, or small

The work rolls have a small skew within the length of the deformed arc, such that the unevenness of the depression and extension occurs along the width of the strip. Under pressure

When the tension is redistributed in a small amount of area, the tension reaches the yield limit, and the well may equalize the extension in the width direction of the strip.

In fact, when rolling on a multi-roll mill, the deformation of the metal is done by the roll tension and the tension of the coil established by the coiler.

Into.

The unit tension used in a multi-roll mill depends on the physical-mechanical properties of the material and the degree of cold work hardening.

Material thickness and its edge quality. The general unit tension is 20 % to 70 %.

In order to achieve the large unit tension and total tension necessary for a stable rolling process, it is required to be provided in a multi-roll mill.

High power drive coiler. Generally, the power of the 20-roller coiler motor reaches 70 % of the main drive power of the mill.

80 %, and some even reach 100 %.

The tension of each pass is determined as follows. In general, when the first pass is rolled, the take-up tension of the pickling unit is higher.

Small, in order to avoid causing the gap between the layers of the steel strip to scratch the surface, the back tension of the first track is small, less than the pick-up tension of the pickling unit.

In order to increase the post-tension of the first rolling, a pressure plate is provided on the inlet side of the twenty-roll mill to increase the tension after rolling; the front tension can be

Freely determined according to process requirements. In the subsequent rolling pass, the type and specification of the rolled steel strip are used, or the front tension is adopted.

Greater than the back tension, or the back tension is greater than the front tension. Generally, the pre-rolling tension of the previous one is taken as the pass of this pass.

Tension, the unit front tension is greater than the unit back tension. There are two cases of the front tension ( winding tension ) of the finished pass . For the expansion and contraction reel reeling machine, since the coiling machine can be directly unloaded and the steel coil is directly fed into the hood furnace for tight roll annealing, in order to prevent bonding during annealing, the winding tension should be reduced, and the winding is taken up. When the tension is less than 50Mpa , the probability of annealing and bonding is very low, but the low take-up tension will affect the rolling mill production capacity; for the solid reel reeling machine, since it needs to be re-rolled, it can be re-rolled.

With a small tension (10 - 40Mpa) , it is possible to use a large tension during rolling to increase the mill's production capacity.

The tension of the pass should also be adjusted at any time according to the shape of the plate, especially when the rolled strip is thin. When there is wave in the middle of the material, the tension should be reduced to prevent the edge of the strip from breaking or broken; when the strip produces side waves, the tension can be appropriately increased.

3 speed system

The rolling speed should be determined according to the capacity of the equipment, and the high rolling should be used as much as possible within the speed range allowed by the rolling mill.

The speed is increased to increase the productivity of the rolling mill; meanwhile, as the rolling speed increases, the rolling pressure is correspondingly reduced.

Generally, the first rolling pass uses a lower rolling speed because the first pass is large, and if it is rolled at a high speed.

The system will cause the roller to heat up abruptly. Due to the poor cooling conditions of the multi-roll mill, the life of the roll will be affected. In addition, due to the large longitudinal thickness deviation of the blank, the shape of the plate is not completely consistent with the roll, and the first pass is performed on the blank. Adjustment, the required speed is low; at the same time using high speed and large pressure, the main motor capacity can not be satisfied.

In the subsequent passes, the rolling speed is determined according to the pressing system and the tension system and the power of the main motor, so that the main motor can

The force is brought into play. There is a process of speed up and down speed for each start and brake of each pass. During the rolling process, it should be as far as possible

Less speed regulation to ensure the stability of the rolling, so as to achieve the uniformity of the thickness deviation.

4 roll shape

Due to the rigidity and zero crown design of the twenty-high mill stand and the various effective adjustment methods of the roll shape,

The twenty-roll mill can be rolled all using a flat roll having no roll crown. The work roll and the second intermediate roll are also as needed

The crown roller can be suitably configured; the first intermediate roller is always a flat roller, but the head has a taper for axial adjustment of the roller; the backing bearing of the support roller cannot have a convexity.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved