300KW high frequency induction heating equipment

300KW high frequency induction heating equipment 250kw high frequency induction heating equipment

250kw high frequency induction heating equipment 200KW high frequency induction heating equipment

200KW high frequency induction heating equipment 160kw high frequency induction heating equipment

160kw high frequency induction heating equipment 120KW high frequency induction heating equipment

120KW high frequency induction heating equipment 80kw high frequency induction heating equipment

80kw high frequency induction heating equipment 60kw high frequency induction heating equipment

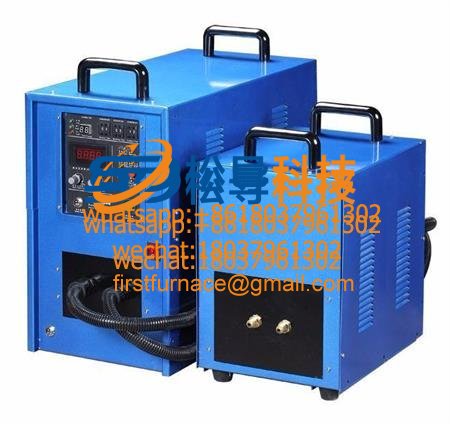

60kw high frequency induction heating equipment 50kw high frequency induction heating equipment

50kw high frequency induction heating equipment 30KW high frequency induction heating equipment

30KW high frequency induction heating equipment high frequency induction heating equipment

high frequency induction heating equipment Drill rod end high frequency heating equipment

Drill rod end high frequency heating equipment Handheld double head induction heating machine

Handheld double head induction heating machine Handheld Induction Heate

Handheld Induction Heate 16kw high frequency induction heating equipment

16kw high frequency induction heating equipmentThe super-audio power supply equipment can be used for the end of various drill rods with diameter specifications of Φ160mm (such as Φ89mm geological drill pipe), heating temperature of 800 °C , and subsequent extrusion molding. Continuous heating, replaces coke heating and traditional heating methods and main features of the oil furnace :

1 , heating speed, electric heating , no pollution, good working conditions;

2 , using imported core components, energy saving;

3. Reduce labor costs and human capital;

4 , the use of hot end processing, saving expensive card heads .

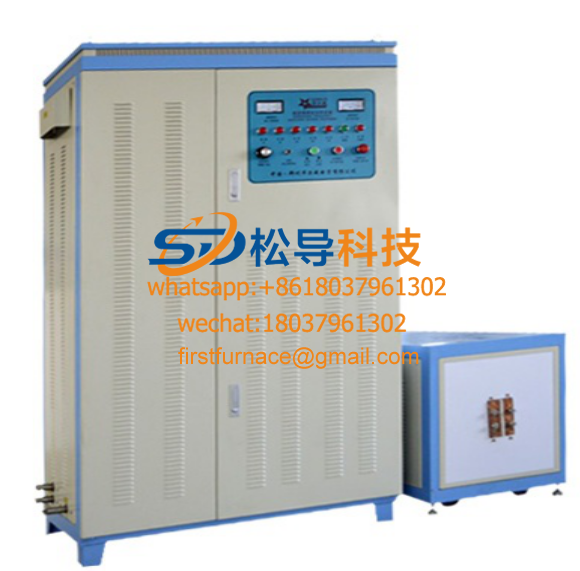

The main parameters of the drill rod end high frequency heating equipment :

The main technical parameters of the power supply

Model: YFL-160

Input power: 160KW

Input voltage: three-phase 380V 50-60HZ

Oscillating frequency: 15-25KHZ 25-35KHZ

volume

160KW main control cabinet 650mm*480mm*1440mm

Transformer cabinet 500mm*800mm*580mm

Three advantages

1 , a substantial power saving, each heating a ton of steel, power consumption of 320 degrees (full red heating). Compared with the thyristor medium frequency power saving 20% -30%.

2 , will not bring network side pollution, power supply transformers do not heat, substation compensation capacitors do not heat, do not interfere with other equipment work.

3. Reduce the capacity of the power supply transformer.

It is also possible to perform surface hardening of various workpieces, welding of a composite drill bit, etc. by replacing the high frequency head, that is, the induction coil. Adjust the power knob to operate. Achieve multi-purpose effects

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved