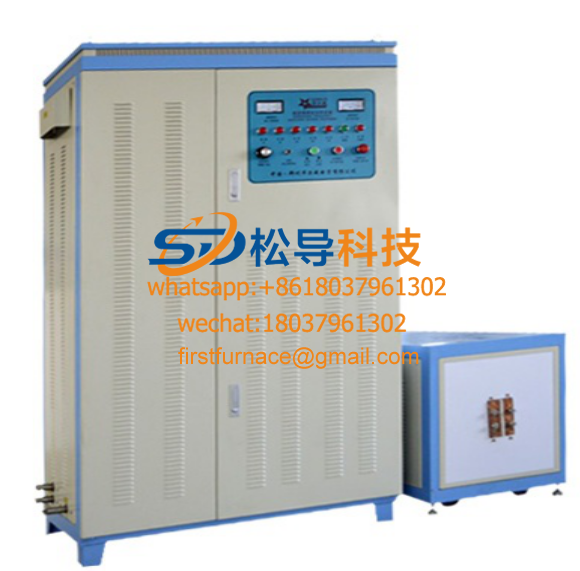

300KW high frequency induction heating equipment

300KW high frequency induction heating equipment 250kw high frequency induction heating equipment

250kw high frequency induction heating equipment 200KW high frequency induction heating equipment

200KW high frequency induction heating equipment 160kw high frequency induction heating equipment

160kw high frequency induction heating equipment 120KW high frequency induction heating equipment

120KW high frequency induction heating equipment 80kw high frequency induction heating equipment

80kw high frequency induction heating equipment 60kw high frequency induction heating equipment

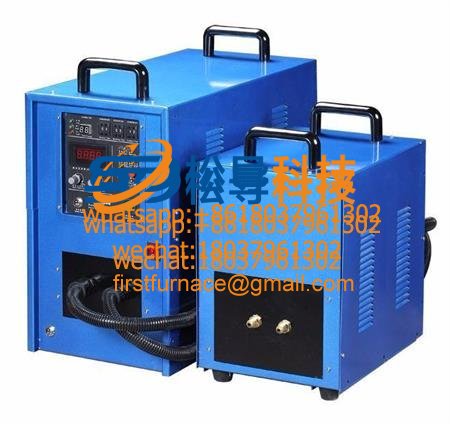

60kw high frequency induction heating equipment 50kw high frequency induction heating equipment

50kw high frequency induction heating equipment 30KW high frequency induction heating equipment

30KW high frequency induction heating equipment high frequency induction heating equipment

high frequency induction heating equipment Drill rod end high frequency heating equipment

Drill rod end high frequency heating equipment Handheld double head induction heating machine

Handheld double head induction heating machine Handheld Induction Heate

Handheld Induction Heate 16kw high frequency induction heating equipment

16kw high frequency induction heating equipmentModel: HSD-160

Input power: 160KW

Input voltage: 360V ~ 420V

Oscillation frequency: 25 ~ 45KHz

Application areas:

1. Dielectric forging of round steel with a diameter of 50mm or less.

2 , Φ 400mm discs, Φ 150mm or less shaft quenching.

3. The machine guide rail is quenched.

4 , quenching treatment of auto parts and motorcycle parts.

5 , heat treatment of workpieces such as pliers, wrenches, screwdrivers, hammers, axes, etc.

Split design, suitable for a variety of different environments to operate. It consists of a rectification part, a filtering part, an inverter part, a main control part, a driving part, a transformer unit, etc., and is fully protected.

Technical Parameters:

Working power | Three-phase380V/50Hz | Cooling water flow (host) | 32L/Min ( 0.1MPa ) |

Operating voltage range | 360V ~ 420V | Cooling water flow (transformer) | 29L/Min ( 0.1MPa) |

Input Current | 240A | Cooling water pressure | 0.1 to 0.3 MPa |

Output Power | 160KW | Host weight | 85Kg |

Oscillating frequency | 25 to 45KHz | Transformer weight | 105Kg |

Transformer dimensions (mm3 ) | 500 × 800 ×580 | Mainframe dimensions ( mm3 ) | 650 × 480 ×1440 |

Features:

1. IGBT is used as the main device and full-bridge inverter, with perfect protection function and high reliability.

2 , remote control and matching infrared temperature measurement, automatic temperature control, improve heating quality and simplify worker operation.

3 , replace the oxy-acetylene flame, coke oven, salt bath furnace, gas furnace, oil furnace and other heating methods.

4 , using frequency automatic tracking and multi-channel closed-loop control, easy to install, easy to operate.

What is the difference between high frequency induction heating equipment and medium frequency induction heating equipment?

High-frequency induction heating: It has a hardened depth of 0.5 to 2 mm (mm). It is mainly used for small and medium-sized parts that require thin hardened layers, such as small modulus gears and small and medium-sized shafts.

Medium frequency induction heating:

The effective hardening depth is 2 to 10 mm (mm), which is mainly used for parts requiring deep hardened layers, such as medium-modulus gears, large-modulus gears, and larger-diameter shafts , but with different thicknesses .

Six problems in the use of induction heating equipment

After years of research and development of induction heating equipment, our company has summarized several major problems that often occur during the use of induction heating equipment for users' reference.

Induction heating equipment in use problems:

1. When the overheat protection alarm occurs, the possible causes are: too little cooling water, insufficient water flow, poor water quality, and blockage of the waterway;

Second, the work is easy to jump and suddenly stop working, the possible reason is: the workpiece enters and exits the induction coil speed is too fast, there is a short-circuit sparking phenomenon between the workpiece and the induction coil or the induction coil itself, the gap between the workpiece and the induction coil is too small, homemade The shape of the induction coil is not correct;

3. When the water shortage protection alarm occurs, the reason may be: the water pipe is reversed, the pump power or pressure flow is insufficient (the machine cooling pump cannot be used), the water quality is poor, and the waterway is blocked;

4. When an overvoltage protection alarm occurs, the cause may be: the grid voltage is too high, more than 10% of the rated voltage, and used when the power consumption is low;

5. When an overcurrent protection alarm occurs, the cause may be: the shape of the self-made induction coil is incorrect, the distance between the workpiece and the induction coil is too small, the short circuit between the workpiece and the induction coil or the induction coil itself, and the prepared induction coil In use, affected by the customer's metal fixture or adjacent metal objects;

Sixth, when the phase loss protection alarm occurs, the reason may be: three-phase power is seriously unbalanced, three-phase power is missing one phase, air switch or power supply line has one way open circuit.

Is the radiation from the high frequency induction heater harmful?

According to the scope set by the IEEE (International Electro-Electrical Engineering Association):

1. When the magnetic field is in the frequency range from about 0.1MHz to about 300MHz , the magnetic field generated by the magnetic field exceeds 3 milligauss, which is harmful to the human body. The magnetic field damage of 90MHz to 300MHz , and the downward, the closer to 0.1MHz . The magnetic field, the smaller the damage, the damage to the magnetic field below 0.1MHz , it is even more insignificant. Of course, in the harmful range, its intensity is below 3 milligauss, which is generally regarded as a range.

2, the electromagnetic wave harm to the 90MHz to 300MHz, 300MHz or more the closer 12000MHz, the smaller the degree of injury, it is thus that, before the "Big Brother" in our use of the frequency 900MHz and 1800MHz, it belongs in the hazardous range. As for the industrial heating electromagnetic movement, the frequency is 17~24KHz , which belongs to the super-audio signal ( 20~25kHz range). Except for some slight noise, other damage to the human body.

3 , the frequency and principle of industrialized electromagnetic heating is basically the same as that of household induction cookers. Now, household induction cookers have entered thousands of households, but it is undoubtedly doubtful. In fact, the distance between the magnetic lines of the induction cooker is very short, and only 3cm or less has effect on iron. You may wish to do a simple test to increase the bottom of your induction cooker slightly by 1cm . The electromagnetic induction at the bottom of the pot is rapidly attenuated, and our industrial electromagnetic heating, the coil is more than 1500mmaway from the operator , the danger is completely negligible. Excluding.

4 , modern life is inseparable from electromagnetic waves, and the space we live in is also filled with electromagnetic waves of various wavelengths like sunlight. If there is no sunlight in the earth, everything will lose its life, so the sun is a beneficial electromagnetic wave for people. In addition, there are many infrared devices, which are also beneficial to the human body. Electromagnetically heated electromagnetic radiation is not beneficial, but it does not pose a hazard to the human body. It is tested to be about one-sixtieth of the time when the mobile phone is connected. Can be used with confidence.

Frequency unit conversion: 1MHz=1000KHZ=1000,000Hz

How to choose high frequency induction heating equipment?

Heating type | Application range | Frequency selection | Power selection |

Brazing | Drills, turning tools, reamers, milling cutters, drill bits, etc. and composite welding of different materials on stainless steel pot bottom . | Principle: The larger the welding volume, the lower the frequency should be.Tools with avolume less than 30*30*30can be used at heights; greater than30*30*30 , medium frequency can be used. Principle: The larger the diameter of the workpiece, the lower the frequency should be. | It depends on the specific workpiece shape, material, solder, etc. |

Diathermy | Fasteners, standard parts, auto parts, hardware tools, copper, twist hot upsetting hot rolling. | Φ20 or more ,medium frequency (1-20KHZ) Φ5-20, high frequency (20-100KHZ) Below Φ5 , UHF(100-500KHZ) | According to the production efficiency, choose the right power , the higher thepower, the faster the speed.Specific can consult the company's technical staff . |

Quenching | Shafts, gears, sprockets, machine tool rail accessories, quenching, etc. | Principle: The shallower the hardened layer is required for the workpiece, the higher the frequency should be. 1-2.5mm super audio 20-100KHZ Medium frequency 1-20KHZ above2.5mm ; | Combined with the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements and materials, etc., you can consult the company's technical staff. |

annealing | Metal wire pipe annealing, hydraulic fittings, auto parts, knife and pliers, stainless steel pot annealing, etc. | Combined with the requirements of workpiece annealing, annealing speed and materials, you can consult the company's technical staff. | |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved