Medium frequency induction heating copper tube annealing eq

Medium frequency induction heating copper tube annealing eq Medium frequency induction heating copper wire annealing equi

Medium frequency induction heating copper wire annealing equi Copper hot rolling furnace

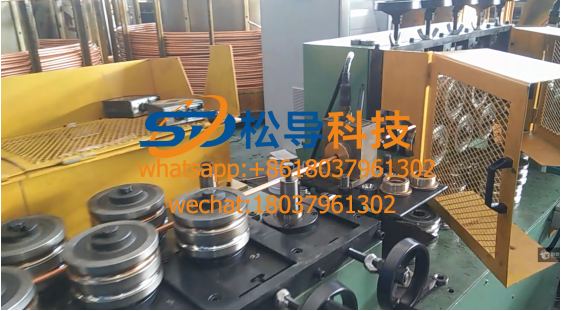

Copper hot rolling furnace  Copper tube medium frequency induction annealing furnace

Copper tube medium frequency induction annealing furnace Copper tube annealing medium frequency induction equipment

Copper tube annealing medium frequency induction equipment  Copper tube annealing equipment

Copper tube annealing equipment  Copper tube annealing furnace

Copper tube annealing furnace Copper pipe annealing

Copper pipe annealing Copper tube heat treatment annealing equipment

Copper tube heat treatment annealing equipment Copper tube induction heating continuous annealing production

Copper tube induction heating continuous annealing production Copper tube induction continuous annealing furnace

Copper tube induction continuous annealing furnace  Copper Tube Induction Heating Continuous Annealing Furnace

Copper Tube Induction Heating Continuous Annealing FurnaceCopper tube induction continuous annealing furnace is often used for heating copper tubes to improve metal thermoplasticity. The metal heating workpiece is placed in the induction coil of the alternating magnetic field, and the copper tube heating device has short heating time, convenient temperature control, guaranteed heating quality, improved working condition produce. Therefore, it has more and more applications.

Summary of technical parameters of copper tube induction continuous annealing furnace

Summary of technical parameters of copper tube induction continuous annealing furnacewith power less than 1000KW | |||||||

Rated power(KW) | Rated frequency (HZ) | Transformer capacity (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage(V) | Power consumption (KW.h/t) | Bar diameter ( mm ) |

80 | 1000~8000 | 100 | 380v | 6 Pulse | 800 | 450 | Φ 6-35 |

100 | 1000~8000 | 160 | 380v | 6 Pulse | 800 | 450 | Φ 25-40 |

120 | 1000~8000 | 200 | 380v | 6 Pulse | 800 | 450 | Φ 30-50 |

160 | 1000~8000 | 250 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

200 | 1000~8000 | 315 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

250 | 1000~8000 | 400 | 380v | 6 Pulse | 800 | 450 | Φ 60-80 |

350 | 1000~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

400 | 500~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

500 | 500~8000 | 630 | 380v | 6 Pulse | 800 | 450 | Φ 120-150 |

1000 | 500~1000 | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

1500 | 500~1000 | 1600 | φ660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

2000 | 500~1000 | 2200 | φ660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

Copper tube induction continuous annealing furnace PLC intelligent control system :

1, the user needs to provide a touch screen or a remote control console

2 , man-machine interface, easy to operate

3 , real-time adjustment of equipment operating parameters

4 , real-time control of the heating process, and has a recording function

5 , different international language switching

Main features of copper tube induction continuous annealing furnace :

1. It is used for heating various metal steel tubes such as carbon steel and iron ;

2 , medium frequency and super audio heating copper tube , more heated, more uniform and faster;

3 , copper tube induction continuous annealing furnace small volume, easy to move, can be used with any forging and rolling equipment;

4 , copper tube induction continuous annealing furnace to make the copper tube heated to the required temperature in a very short time, greatly reducing metal oxidation, saving material and improving forging quality;

5 , automatic feeding, automatic feeding, automatic production capacity;

6, copper induction continuous annealing furnace energy saving, environmental protection, reduce manpower costs and benefits expenses;

7. It is convenient to replace the sensor to meet the different requirements of the overall heating or end heating of the copper tube .

The copper tube induction continuous annealing furnace adopts intelligent induction heating power supply to control its characteristics:

● Parallel resonance design, phase shifting power adjustment, medium frequency annealing furnace mature and stable; more advantages in the high power range above 3000KW .

● DSP control, the speed captures the phase-locked start, meets frequent start and stop, and has a high success rate.

● Variable frequency variable load adaptation, frequency adaptation range 200-10000Hz, induction furnace replacement automatic matching, no manual adjustment is required.

● T2 copper copper row in the cabinet , sandblasted and passivated; low leakage and anti-oxidation, effectively reducing line loss.

● Full touch screen control, pure digital setting, complete process record and strict hierarchical authority. The main parameters can be restored to the factory settings with one key.

● Power single unit power 50-6000KW , frequency 200-10000Hz.

Special advantages of copper tube induction continuous annealing furnace :

1, a simple brass sensing continuous annealing operation, a feed, unloading flexibility, high degree of automation.

2 , medium frequency induction heating equipment heating speed, less oxide layer, good quality.

3. Precisely control the length, speed and temperature of the workpiece.

4. Uniform heating of the workpiece ; the temperature difference from the surface to the core is small ; the control precision is high.

5. Design and manufacture the inductor of the copper tube induction continuous annealing furnace according to your specific requirements .

6. Full range of energy-saving optimization design : low energy consumption and high thermal efficiency.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved