5T Medium Frequency Induction Melting Furnace

5T Medium Frequency Induction Melting Furnace 500kg medium frequency induction melting furnace

500kg medium frequency induction melting furnace 3T medium frequency induction melting furnace

3T medium frequency induction melting furnace medium frequency induction melting furnace

medium frequency induction melting furnace 250kg medium frequency induction melting furnace

250kg medium frequency induction melting furnace 2T medium frequency induction melting furnace

2T medium frequency induction melting furnace 1T Medium Frequency Induction Melting Furnace

1T Medium Frequency Induction Melting Furnace5T medium frequency induction melting furnace consists of:

3000kw intermediate frequency power supply - capacitor cabinet - aluminum shell or steel shell furnace - hydraulic tilting furnace system - remote control box - ZXZ-N320T ( 70/250) closed loop cooling tower.

5T medium frequency induction melting furnace price

The price of the 5T medium frequency induction melting furnace is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. Firstfurnace@gmail.com

Serial number | Item name | Specification model | unit | Quantity | Price ¥ |

1 | IF power cabinet | 3000KW/5T/500HZ | station | 1 | 260000 |

2 | Filter compensation capacitor cabinet | 2 . 0 - 4 000-1S | set | 1 | 100000 |

3 | 5T furnacesteel shell | GW- 5T | set | 1 | 250000 |

4 | Water cooled cable | LHSD- 600 | set | 4 | 30000 |

5 | Model | 5T furnace dedicated | only | 1 | 3000 |

Total: ¥ 643,000 | |||||

Selection of related configuration of 5T medium frequency induction melting furnace

Intermediate frequency power supply | Working form: rectifier series inverter series (SCR) 6- phase12- pulse ( one electric two furnace ) |

The cross-sectional area of the incoming copper bar : 1000mm2 copper row 100x10mm copper row within 10 meters. | |

Cabinet shell: a rectifier cabinet Inverter cabinet a1500x4000x2200mm 1500x1500x2200mm | |

Power efficiency ≥98% Cabinet material: main frame carbon steel, cabinet door: aluminum alloy. | |

Start mode: variable frequency buffer start | |

Startup rate: 100% (including heavy load) | |

Rated frequency: 3 0 0Hz -500Hz | |

AC voltage: 575 V rectifier series | |

DC voltage: 1550 V | |

IF voltage: 3400v | |

DC current: 2340 A | |

Incoming AC current: 1900 A | |

Input frequency: 50Hz | |

Rectifier 2 ways in series and then parallel, inverter form:inverter parallel or inverter series | |

Weight: 5000 KG or so | |

Circulating water volume: closed - loop water cooling towerZXZ-N320T ( 70/250) | |

Furnace body | Rated capacity: 5 0 0 0KG |

Maximum capacity: 5300 KG | |

Rated power: 3500 KW | |

Frequency: 300 Hz | |

Power factor: ≥0.9 6 | |

Working mode: one electric two furnace | |

Melting time : 55 minutes ± 5% | |

Working temperature: 1 550 °C | |

Loading height: 1550 mm Hearth height: 1250mm | |

Loading diameter: 910 mm (upper mouth) inner diameter of the ring: 1100mm ring copper tube is 40x70x8mm | |

Loading diameter: 825 mm (lower) Inner diameter of the ring:1100mm | |

Furnace copper tube: 55x65x8mm 15匝 , weight 2500 , total length: 164 meters | |

Maximum angle of the tilting furnace: 95° | |

Outlet mode: side outlet | |

Yoke : Covering area 80% . Thickness: 0.35mm | |

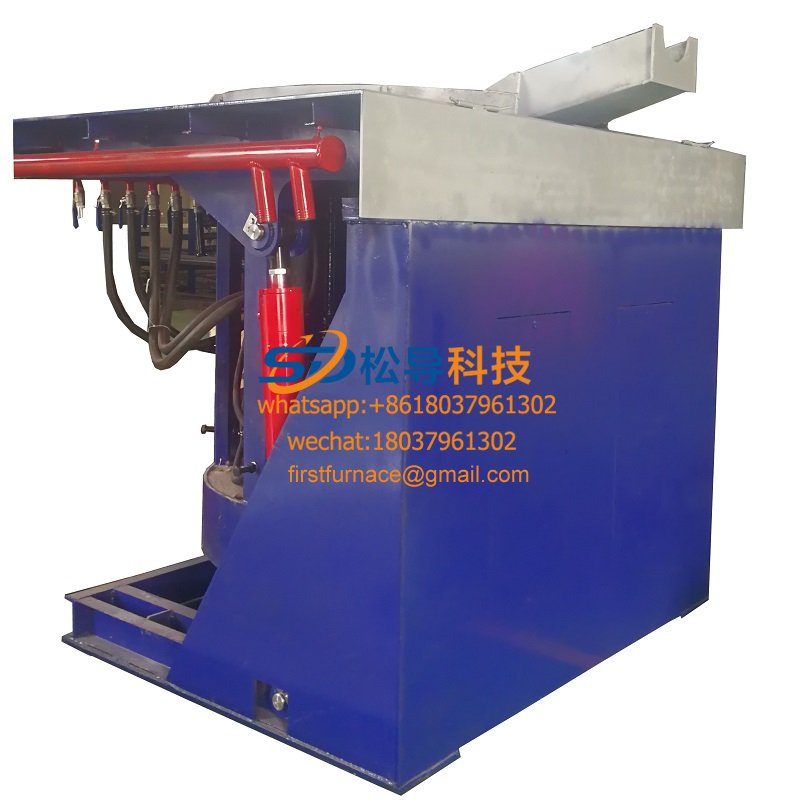

Tilting method: hydraulic | |

Unit power consumption: 520 ± 5% kW.h/t 1550 ° C | |

Working voltage: 3400V | |

Dimensions: | |

transformer | Rated capacity: 3150KVA a |

Primary voltage: 10KV | |

Secondary voltage: 1500v | |

One phase: 3 phase | |

Secondary phase number: 6 phase 12 veins | |

Output form: three △ three Y | |

Hydraulic | Hydraulic cylinder: |

Working pressure: 10Mpa | |

Diameter: Φ 320 plunger cylinder | |

Itinerary: 2 107mm | |

3 flow: > 26L/Min | |

Hydraulic station: | |

Working pressure: 10Mpa | |

Hydraulic pump: double pump double | |

Form: Horizontal | |

Capacity: 12 00L | |

Console | Mode: Electric (action indicator) |

Cooling water system | Integrated layered tower closed - loop water cooling towerZXZ-N320T ( 70/250) |

Cooling capacity 18 0000 0 kcal/h cooling water volume 35 0m3/h Fan power 11 KW × 2 units Fan air volume 12 5000m3/h ×2 Spray pump 190 m3/h ; 4 kw main motor 30kw Dimensions mm 53 00×2 3 00× 4910 (one size) | |

Pipeline | Pipe material: PPR, pipe diameter: DN125X2=DN250 , watersupply port DN65 , total length of water pipe within 30meters. The electrical control cabinet is within 5 meters of the power supply cabinet . |

5T medium frequency induction melting furnace features :

1. Intelligent system, fast protection, durable thyristor, good starting performance, stable operation and convenient operation.

2 , the use of large copper discharge machine, increase the reactor power saving.

3 , induction melting furnace has over voltage, over current, water temperature, water pressure, short circuit, grounding and other protection systems, the operating panel has a working parameter display table , display various parameters of the working state, and there are faults, temperature and other indications.

5T medium frequency induction melting furnace appearance structure

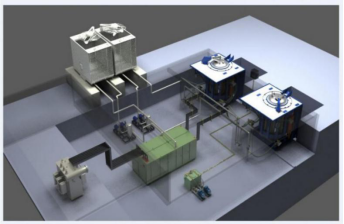

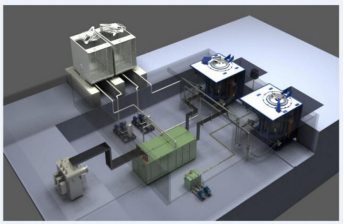

How to arrange 5T medium frequency induction melting furnace ? Please see the figure below for answers.

What information does the customer need to provide to the supplier before purchasing the induction melting furnace?

1. Induction melting furnace should have space for layout, and it is necessary to provide the area and layout of the plant.

2. The customer needs to provide the capacity of the transformer, the magnitude of the incoming line voltage, and the frequency of the incoming line voltage.

3. The induction melting furnace requires water-cooling equipment, and the induction melting furnace configuration contains water-cooling equipment.

4. The furnace structure of the induction melting furnace has a steel shell furnace body and an aluminum shell furnace body, and the customer needs to specify the furnace body structure.

5. The power supply of the induction melting furnace is an intermediate frequency power supply. The circuit structure of the intermediate frequency power supply is divided into an inverter parallel connection and an inverter series structure. The inverter series structure is energy-saving, the power factor is 0.98, and the line is stable. The inverter parallel structure is of the common type with a power factor of 0.92, which requires the customer to specify the line structure.

A good way to correctly and quickly select the " 5T medium frequency induction melting furnace "

1. Selection of Transformer Capacity of 5T Medium Frequency Induction Melting Furnace

5T medium frequency induction melting furnace should choose 3150KVA transformer. The secondary output voltage is 1000v

Selection basis: the value of the transformer capacity = the value of the power supply of the intermediate frequency induction melting furnace x 1.2 The transformer is a rectifier transformer In order to reduce the interference of harmonics, it is as far as possible for the special plane, that is, one intermediatefrequency induction melting furnace is equipped with a rectifier transformer.

1. Selection of Line Voltage of 5T Medium Frequency Induction Melting Furnace

5T medium frequency induction melting furnace power is 3000kw using six-phase 12- pulse 1000V , 50HZ industrial electricity

Selection basis: For medium frequency power supply for medium frequency induction melting furnace below 1000KW , three-phase five-wire 380V and 50HZ industrial power are generally used . For medium frequency induction melting furnace above 1000KW , the focus is on using 660V - 1000v incoming voltage. According to thecapacity requirements, determine the medium frequency induction melting furnace with large tonnage.

The capacity of the induction melting furnace can be determined by the weight of the individual pieces and the weight of the molten iron required for each working day .

The standard tonnage is as follows:

250kg induction melting furnace

500kg induction melting furnace

1T medium frequency induction melting furnace

2 T medium frequency induction melting furnace

3T induction melting furnace

5 T induction melting furnace

4. Selection of 5T medium frequency induction melting furnace body structure

The capacity of the 5T medium frequency induction melting furnace is small. The recommended choice is: the furnace body of the hydraulic steel shell .

The aluminum alloy structure commonly known as the aluminum alloy structure with the reducer as the tilting furnace method. The induction melting furnace of the steel structure with the hydraulic cylinder as the tilting furnace is commonly called the steel shell furnace. The steel shell furnace is a steel structure, and the aluminum shell furnace shell material is an aluminum alloy .

Determination of energy consumption of 5T medium frequency induction melting furnace

The electric power of the induction melting furnace is higher and the power is saved. The energy consumption of the molten iron in the 5T medium frequency induction melting furnace : 5 5 0KW.h/t , energy consumption of molten steel 6 0 0 KW.h/t .

How to choose the induction melting furnace lining material?

1. Induction melting furnace lining material is divided into acid lining material, alkaline lining material, neutral lining material, coil cement, root melting material, medium frequency electric furnace tonnage, product molding temperature is different, it is very important to choose the appropriate lining material. jobs.

2. Induction melting furnace is a molten steel furnace using alkaline lining material mainly for fused magnesia. The induction melting furnace is a molten iron furnace. The acid lining material is a refractory material for quartz coreless induction furnace, and the material is acidic.

How to increase the melting speed of the induction melting furnace?

1. Increase the power of the induction frequency melting furnace intermediate frequency power supply.

2. Choose a reasonable charge size and the correct feeding method.

3. Appropriate molten iron outlet temperature.

PREV:500kg medium frequency induction melting furnace

NEXT:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved