Round steel induction heating furnace automatic control system selection method

1, the equipment composition of the automatic control system:

a, industrial grade LCD screen

b, a set of industrial control configuration software (MCGS system)

c, a set of programmable controllers (SIEMENS SIMATIC S7-200)

d, monochrome infrared thermometer 1 (Raytek, USA)

e, photoelectric and proximity switch 1 set (Japan OMRON)

f, control cabinet (including variable frequency drive equipment), operation console, etc.

2, the function of the automatic control system:

a, stable and reliable temperature closure control, real-time acquisition, recording, storage process control data and corresponding classification search, query, print function.

b. Real-time detection of process control effect; in the process of equipment operation, real-time analysis of the follow-up state of the monitoring and diagnosis equipment, timely display of prompts for Chinese characters in various abnormal situations, and sound and light alarm.

c. Convenient and quick operation mode conversion (just switch the “automatic” “manual” switch on the console to switch between the two. In the self-controlled operation state, it can also manually participate in the power supply or running speed. Adjustment. (The manual adjustment data system will be recorded in real time)

d. According to the need, the operator can implement the verification function of setting password and password, and the management function of production record inquiry and printing authority.

e, clear and friendly operation interface, all kinds of operations at a glance, you can get started without having to memorize the complicated operation rules.

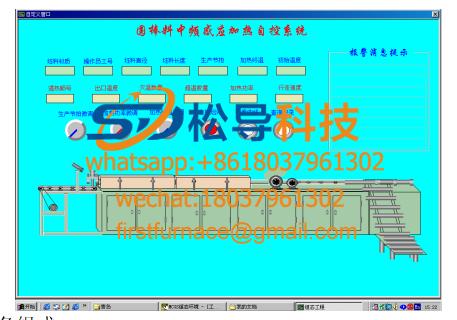

3, the operation interface of the automatic control system:

a, the main control interface: as shown in the figure above. In this interface, the input of production data can be operated through the parameter input field in the upper left part, and the main data of the production process is displayed in the next line of this operation bar. In the production process, you can also fine tune the production tempo, the power of the intermediate frequency power supply and the set outlet temperature through the three fine adjustment knobs below this section to get better heating effect.

The upper right part of the interface displays and prompts Chinese characters for the fault conditions that occur during the operation of the device. When the device is abnormal, the corresponding device warning light will flash.

The two white electronic buttons set in this interface are the operation buttons that go to the “Temperature Curve” interface and the “Data Query” interface. To exit the run, simply click the "Exit Run" button in the lower right corner to exit the autorun state.

b. Temperature curve display interface: In this interface, the measurement curve of each infrared material of the infrared thermometer is displayed.

c, data acquisition interface:

In this interface, you can control the collection of production data. Setting the role of this interface is extremely convenient for data detection and debugging during the operation of the device.

d. Production data record interface: This interface is a record of the real-time data of the production process. The query button in the lower right corner of the interface can enter the data query interface.

e, data query interface

The data query interface is shown in the figure above. In this interface, the classification is temporarily divided into four types of query methods. If you need to add other categories, you can easily set them. In the operation of this interface, you can browse or print after entering the query category and range.

f, data print list

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved