Aluminum melting furnace

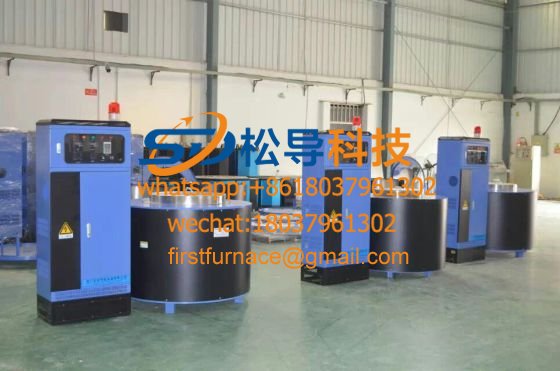

Aluminum melting furnace 800KG electromagnetic melting aluminum furnace

800KG electromagnetic melting aluminum furnace 600KG electromagnetic melting aluminum furnace

600KG electromagnetic melting aluminum furnace 400KG electromagnetic melting aluminum furnace

400KG electromagnetic melting aluminum furnace 350KG electromagnetic melting aluminum furnace

350KG electromagnetic melting aluminum furnace 250KG electromagnetic melting aluminum furnace

250KG electromagnetic melting aluminum furnace 200KG medium frequency aluminum melting furnace

200KG medium frequency aluminum melting furnace 200KG electromagnetic melting aluminum furnace

200KG electromagnetic melting aluminum furnace Aluminum melting furnace

Aluminum melting furnace 100kg electromagnetic melting aluminum furnace

100kg electromagnetic melting aluminum furnace 50KG medium frequency aluminum melting furnace

50KG medium frequency aluminum melting furnace medium frequency aluminum melting furnace

medium frequency aluminum melting furnaceThe electromagnetic melting aluminum furnace is a metal melting equipment developed by our company for use below 1000 °C. Its functions have the following characteristics:

1, energy savings: aluminum average power of 0.4 ~ 0.5 / KG aluminum, more than 30% saving over traditional stoves;

2 , efficient use: 1 hour 600 ° rising temperature, heating speed is super fast, lasting constant temperature;

3 , environmental protection and low carbon: in line with national energy conservation and emission reduction policies, no dust, no fumes, no harmful emissions;

4 , security and stability: independent research and development of 32 -bit CPU technology, with leakage, aluminum leakage , overflow, power failure and other intelligent protection;

5 , aluminum slag less: electromagnetic eddy current induction heating, no heating dead angle, high utilization of raw materials;

6 , life extension: 坩埚 heat evenly, the temperature difference is small, the life expectancy is extended by 50% ;

7, precise temperature control: eddy current transient response, self-heating of the crucible, no conventional heating hysteresis;

1, for the industry:

Aluminum die-casting plant, plant aluminum ingot, melting the aluminum industry waste, the casting plant, the production of automobile and motorcycle parts, cell phone housings, lamps, electric cooker heating plate manufacturer

2 , product introduction:

Electromagnetic melting aluminum furnace is the best energy-saving electromagnetic melting aluminum equipment to replace traditional resistance type, coal-fired, fuel oil and medium frequency furnace . With the rising cost materials, all walks of life are facing fierce market competition, and the increase of electricity costs is even more The metallurgical industry is worse. The emergence of electromagnetic melting aluminum furnace solves various problems in the metallurgical industry. It has the advantages of intelligence, security, money saving, environmental protection and other national support, and is sought after by the metallurgical industry.

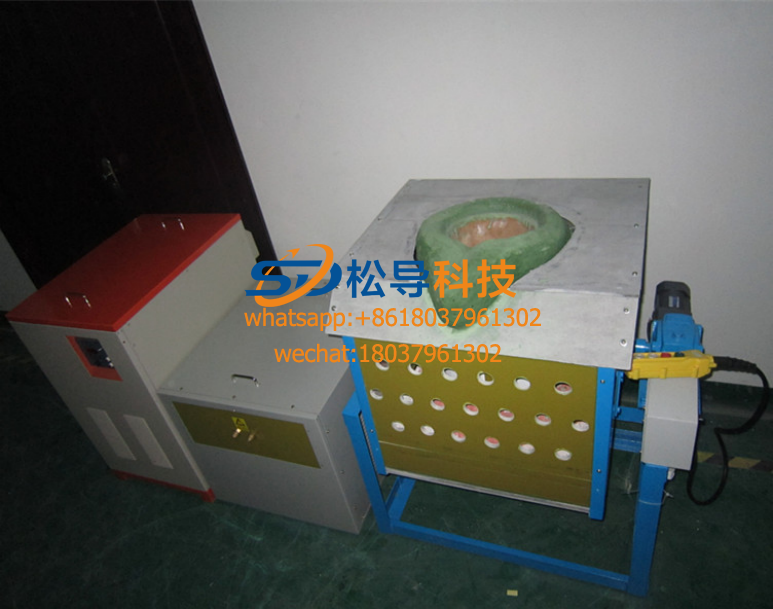

3 , product classification: 100kg electromagnetic melting aluminum furnace

Model: SD -AI- 100 KG

Smelting furnace lining : silicon carbide graphite crucible

Crucible Material: Aluminum Alloy

坩埚 Capacity: 250KG

Rated power: 60KW

Melt capacity / ton: 380 kWh / ton

Insulation power consumption / hour: 1 degree electricity / hour

Melting speed kg / hour: 80 KG / hour

4 , heating principle:

The electromagnetic melting furnace converts electrical energy into thermal energy by an electromagnetic induction heating controller using an electromagnetic induction heating principle. First, the internal alternating current is converted into direct current through an internal rectification and filtering circuit, and then the direct current is converted into high frequency magnetic energy through a control circuit. A high-speed current passing through the coil generates a magnetic field that changes at a high speed. When the magnetic field lines in the magnetic field pass through the crucible, numerous small eddy currents are generated inside the crucible, so that the crucible itself is heated at a high speed, heat is transferred to the aluminum alloy, and dissolved into a liquid. .

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved