Aluminum melting furnace

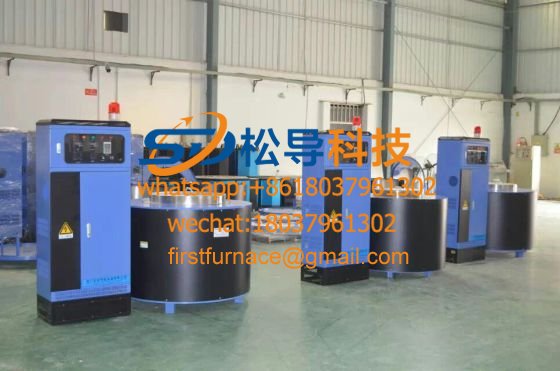

Aluminum melting furnace 800KG electromagnetic melting aluminum furnace

800KG electromagnetic melting aluminum furnace 600KG electromagnetic melting aluminum furnace

600KG electromagnetic melting aluminum furnace 400KG electromagnetic melting aluminum furnace

400KG electromagnetic melting aluminum furnace 350KG electromagnetic melting aluminum furnace

350KG electromagnetic melting aluminum furnace 250KG electromagnetic melting aluminum furnace

250KG electromagnetic melting aluminum furnace 200KG medium frequency aluminum melting furnace

200KG medium frequency aluminum melting furnace 200KG electromagnetic melting aluminum furnace

200KG electromagnetic melting aluminum furnace Aluminum melting furnace

Aluminum melting furnace 100kg electromagnetic melting aluminum furnace

100kg electromagnetic melting aluminum furnace 50KG medium frequency aluminum melting furnace

50KG medium frequency aluminum melting furnace medium frequency aluminum melting furnace

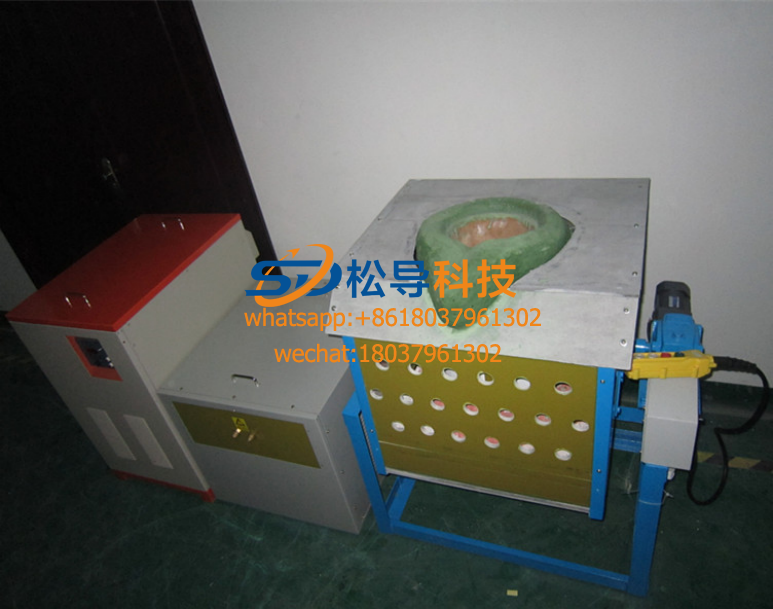

medium frequency aluminum melting furnaceOverview: The medium frequency aluminum melting furnace is widely used in the aluminum industry . The medium frequency melting aluminum furnace has less loss of melting aluminum than the power frequency furnace; the medium frequency melting aluminum furnace is more efficient than the electric resistance furnace; the medium frequency melting aluminum furnace can increase the melting by increasing the power. Rate; under the same power, the medium frequency melting aluminum furnace has less noise than the power frequency furnace, and the smoke pollution is less.

The composition of the medium frequency melting aluminum furnace : the whole set of intermediate frequency power supply frequency 2500HZ , compensation capacitor, furnace body and water-cooled cable, reducer.

The intermediate frequency melting aluminum furnace technical parameters configuration summary

model | Summary of technical parameters of medium frequency aluminum melting furnace | ||||

Rated Capacity | rated power | Operating temperature | Melting rate | frequency | |

GWJTZ0.3-160-1 | 0.3 | 160 | 700 | 0.25 | 1000 |

GWJTZ0.5-250-1 | 0.5 | 250 | 700 | 0.395 | 1000 |

GWJTZ1.0-350-1 | 0.8 | 350 | 700 | 0.59 | 1000 |

GWJTZ1.0-500-1 | 1.0 | 500 | 700 | 0.89 | 1000 |

GWJTZ1.6-750-1 | 1.6 | 750 | 700 | 1.38 | 1000 |

GWJTZ3.2-1500-0.5 | 3.2 | 1500 | 700 | 2.38 | 1000 |

GWJTZ5.0-2500-0.35 | 5 | 2500 | 700 | 4 | 1000 |

The intermediate frequency melting aluminum furnace is different from the medium frequency melting iron furnace

Aluminum is a non-magnetic material . During the entire melting process , the magnetic field is very easy to diverge , so the yoke arrangement should be reasonable. First, the area of the yoke must be large enough, as long as possible, in order to ensure axial and radial magnetic field sensor through a sufficient edge. If the inductor is a two-stage coil ( parallel rewind ), consider the magnetic flux leakage problem at the indirect slot. Secondly , the distance between the sensors is not too large , and it is suitable for 8 - 12mm .

Medium frequency melting aluminum lining selection

IF aluminum furnace due to the high frequency, high frequency vibration of molten aluminum, the combined aluminum own characteristics, which is particularly strong penetration, the lining is critical. A special furnace lining for aluminum furnaces should be used . Generally, a good furnace lining can use more than 300 heats.When aluminum is melted, the eddy current generated is large. In the early stage of melting, due to the irregular distribution of the charge, the power supply is subjected to a strong impact, and the thyristor is easily burned out. Therefore, when manufacturing the intermediate frequency power supply, the impact resistance should be considered.

The summary of the advantages of the intermediate frequency aluminum melting furnace

Medium frequency aluminum melting furnaces are widely used in the aluminum industry.

1, aluminum melting furnace IF than the frequency loss is small aluminum melting furnace;

2 , medium frequency aluminum melting furnace is more efficient than electric resistance furnace ;

3 , medium frequency aluminum melting furnace can increase the melting rate by increasing the power ;

4, the same intermediate frequency than the frequency melting furnace at the furnace noise power, less dust pollution.

Because the medium frequency aluminum melting furnace has many advantages , it is widely used.

The energy loss summary of the induction heating process of the intermediate frequency aluminum melting furnace:

1. Heat loss due to current flowing through the inductor: This loss is carried away by the cooling water. This part of the loss is the main loss of the system, which is related to the structure of the inductor, the physical properties of the charge, and the heating frequency. The "electrical efficiency" is commonly used to describe this loss. Electrical efficiency is the ratio of the energy delivered to the heated workpiece to the energy obtained by the inductor from the power source.

2 , heat loss: the loss caused by the heat of the heated workpiece to the surrounding, this part of the loss is second only to the inductor loss. The commonly used "thermal efficiency" describes the loss, which is the ratio of the net heat that heats the workpiece to the total heat that the workpiece receives from the induction coil.

3. Transmission loss: The loss caused by the cable and busbar from the variable frequency power supply to the load is generally 2% to 7% .

4 , conversion loss: the converter components in the power cabinet, filter inductors, converter inductors, compensation capacitor losses, generally 2% ~ 5% .

6, intermediate frequency melting furnace efficiency of 62%, the thermal efficiency can reach 75% conversion loss is 3%, the transmission loss is 5%.

Medium frequency aluminum melting furnace safety operation guide

1, before starting, first check the water, gas, electricity is turned on, the following operations can be carried out after turning;

2 , the operator must prepare the corresponding insulation shoes, gloves and so on.

3, the operator must have the appropriate electrical knowledge.

4, before the equipment maintenance must pull out the gates is determined after the power off, then discharge treatment, and then hang up after the access card, repeated maintenance, such as the need charging operation, more than two must be present, but never allow high pressure operation with .

5 , before starting, first determine that the waterway is normal, all parts of the equipment are normal to allow booting.

6, a first open filament speed, second speed for five minutes apart filament, then after five minutes, before the high pressure feed.

7, before sending a high pressure, the output is determined at a minimum position adjustment potentiometer, and then sending a high pressure, and the voltage of the output voltage to adjust the work.

8, after the workpiece is determined, the heating button press can make the device work, but never allow the heating load.

9, such as at work, the device abnormal situation, the power supply must be disconnected immediately after the check clarity reasons, work.

10, after the work is completed the device, disconnect the heating, and then disconnect the high pressure, and then the filament off the power supply.

11, after the device stops working, you must wait five minutes later, then disconnect the water.

12, during a working device, such as a temporary emergency must leave, it shall be done, people from the machine stopped, must not be allowed, when no one machine is still working.

Medium frequency aluminum melting furnace maintenance and maintenance guide

1, proper care and maintenance, it can ensure that equipment has good performance and long service life.

2, class work after completion of the device in addition to water: method is to use an air gun to dry the water droplets, the work surface dust and debris clean, ensure clean equipment, clean.

3 , water cooling requirements: water cooling is extremely important for induction heating equipment, poor water quality, will lead to rust and scale inside the equipment, pipeline blockage, will directly lead to equipment damage, can not work properly.

4, the coil is prohibited in the case where no through water heating, otherwise the coil will burn, because the no-load power will burn.

5 , recommended cooling water: distilled water - softened water - pure water - filtered tap water

6. Cooling water that is strictly prohibited: seawater, salt water, unfiltered river water and well water.

7, the recommended water supply: water + closed loop water cooling heat exchanger.

8, a three-phase input voltage 380V (three-phase five-wire power supply).

9, after the machine is powered Do not touch the power transformer all input and output connectors, so as to avoid accidents.

10, the air must turn off the switching device, the main switch and external maintenance equipment, stopping the flow of water equipment.

11, the device should be placed to avoid sun exposure, rain, moisture and other environmental.

12 , equipment maintenance should be carried out by professionals.

13. When the control box door is not closed , do not turn on the power to avoid a safety accident.

14, when the work is completed first turn off the power control box, to stop the water after 15 minutes, so as not to damage the power supply

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved