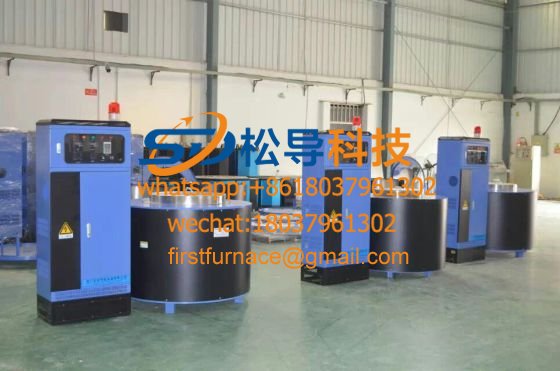

Aluminum melting furnace

Aluminum melting furnace 800KG electromagnetic melting aluminum furnace

800KG electromagnetic melting aluminum furnace 600KG electromagnetic melting aluminum furnace

600KG electromagnetic melting aluminum furnace 400KG electromagnetic melting aluminum furnace

400KG electromagnetic melting aluminum furnace 350KG electromagnetic melting aluminum furnace

350KG electromagnetic melting aluminum furnace 250KG electromagnetic melting aluminum furnace

250KG electromagnetic melting aluminum furnace 200KG medium frequency aluminum melting furnace

200KG medium frequency aluminum melting furnace 200KG electromagnetic melting aluminum furnace

200KG electromagnetic melting aluminum furnace Aluminum melting furnace

Aluminum melting furnace 100kg electromagnetic melting aluminum furnace

100kg electromagnetic melting aluminum furnace 50KG medium frequency aluminum melting furnace

50KG medium frequency aluminum melting furnace medium frequency aluminum melting furnace

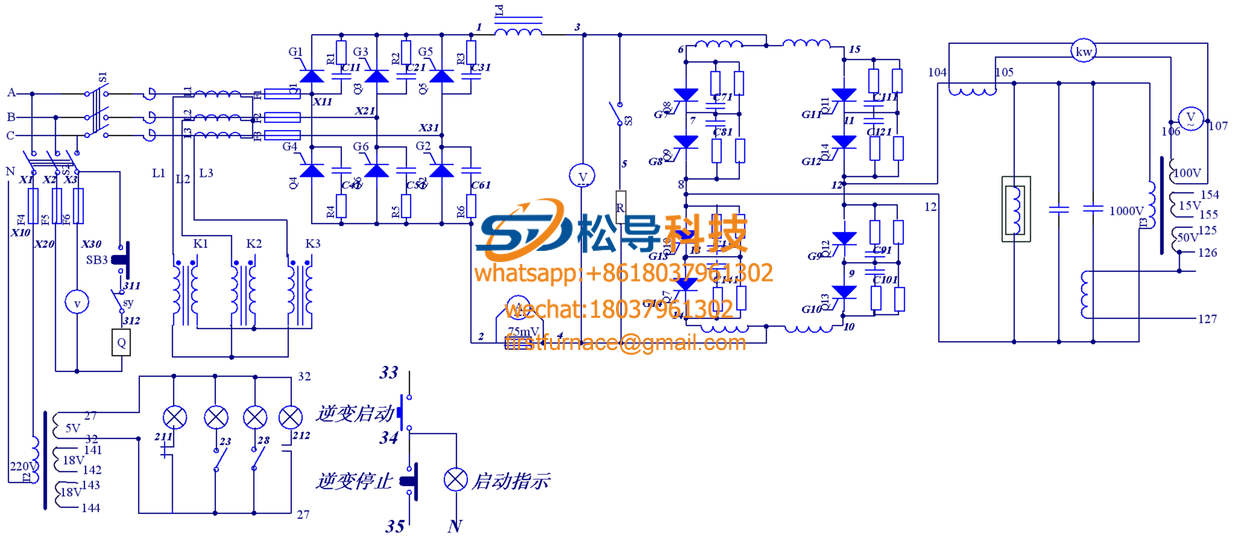

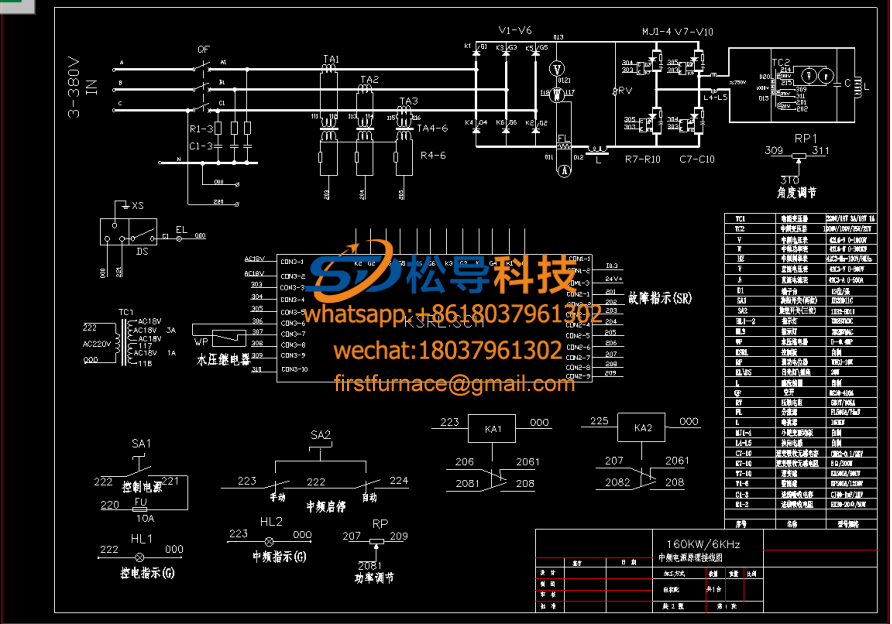

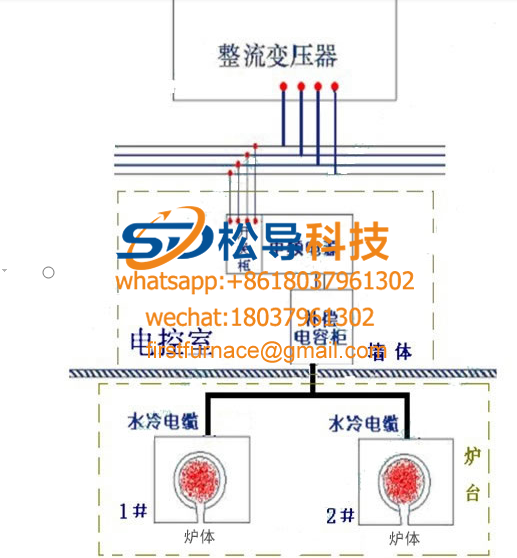

medium frequency aluminum melting furnace Intermediate frequency furnace main circuit schematic

Intermediate frequency furnace main circuit schematic 160kw medium frequency induction heating furnace electrical s

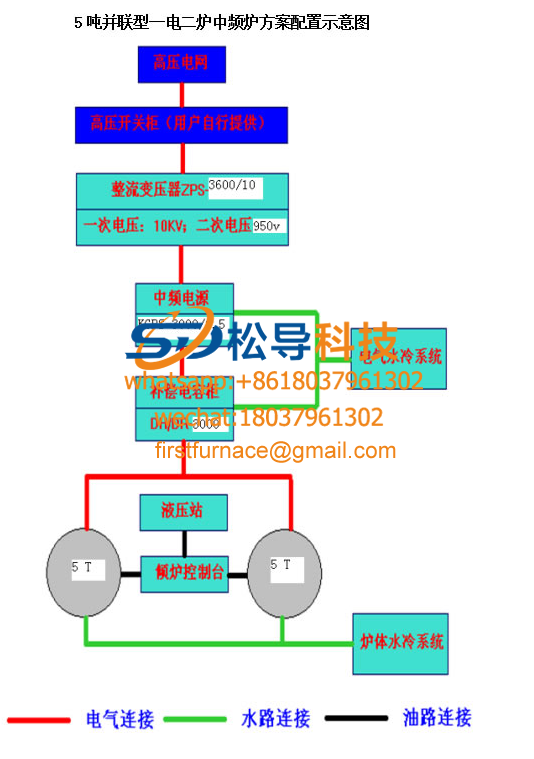

160kw medium frequency induction heating furnace electrical s Schematic diagram of 5 tons of intermediate frequency melting

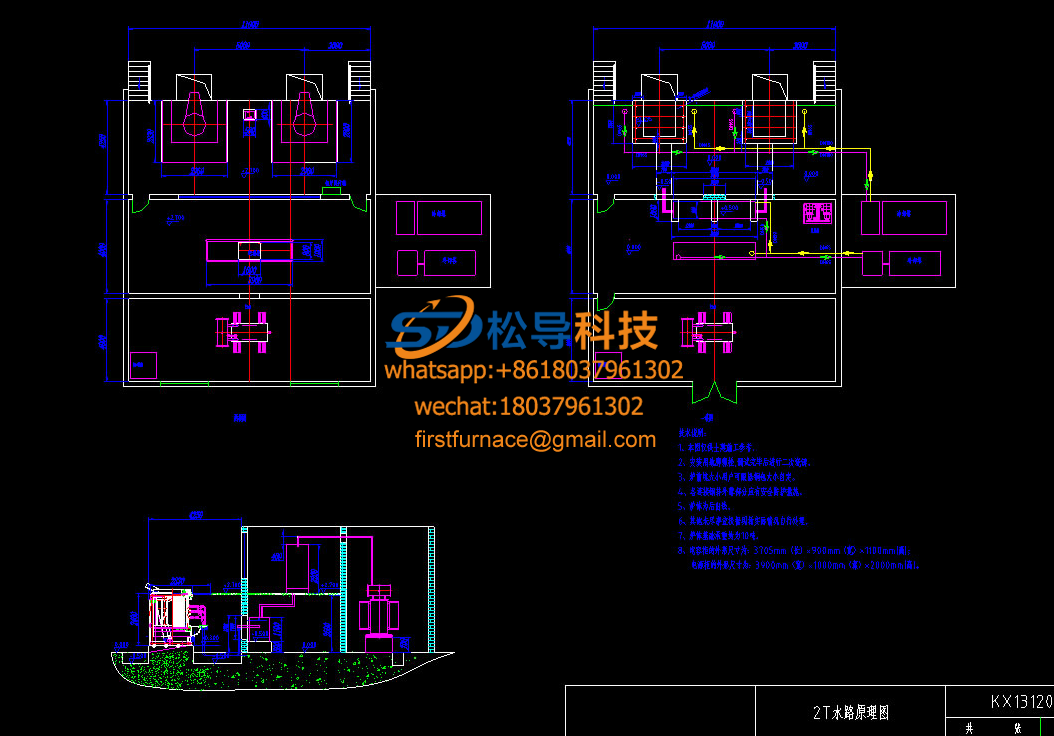

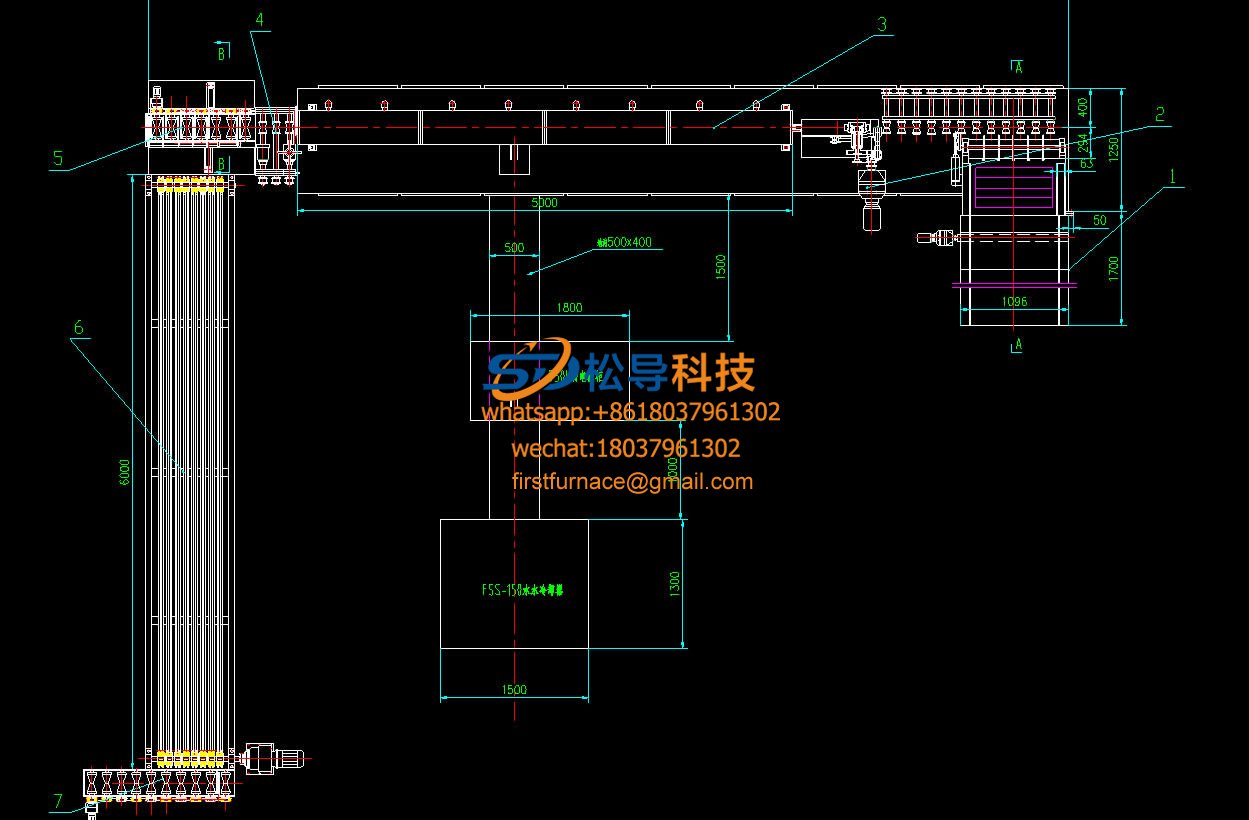

Schematic diagram of 5 tons of intermediate frequency melting 2 tons intermediate frequency furnace floor plan

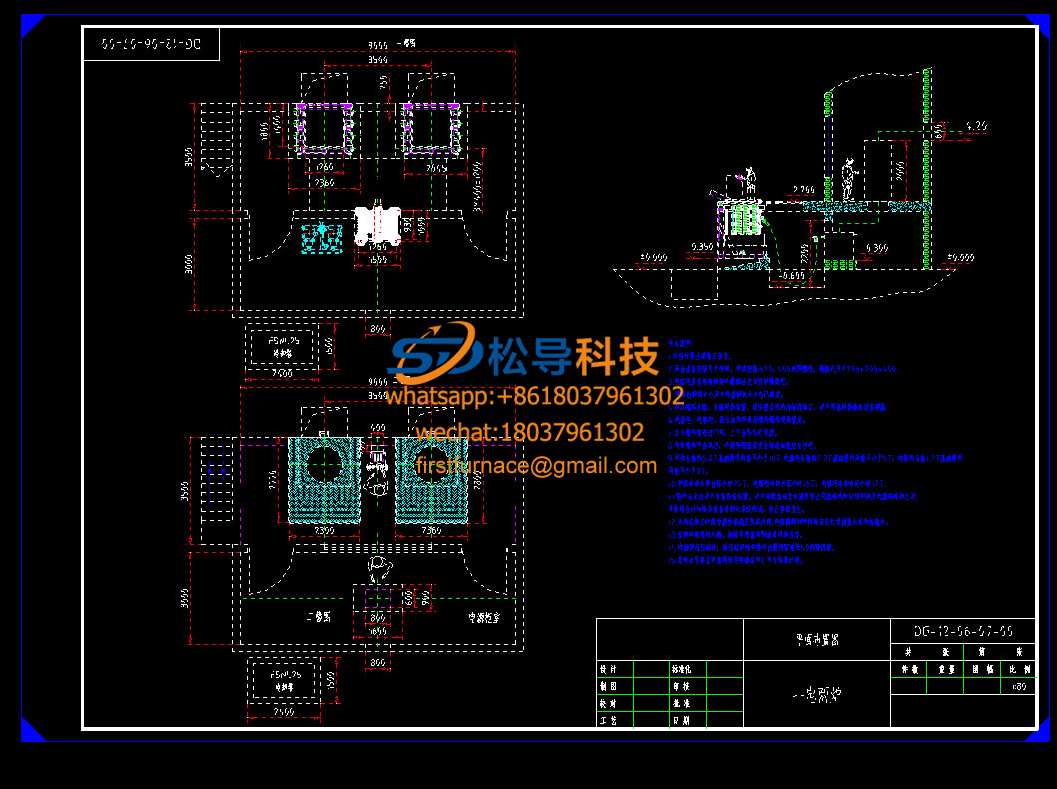

2 tons intermediate frequency furnace floor plan Schematic diagram of plane layout of 1 ton medium frequency i

Schematic diagram of plane layout of 1 ton medium frequency i Technical Drawing of Simple Layout of Intermediate Frequency

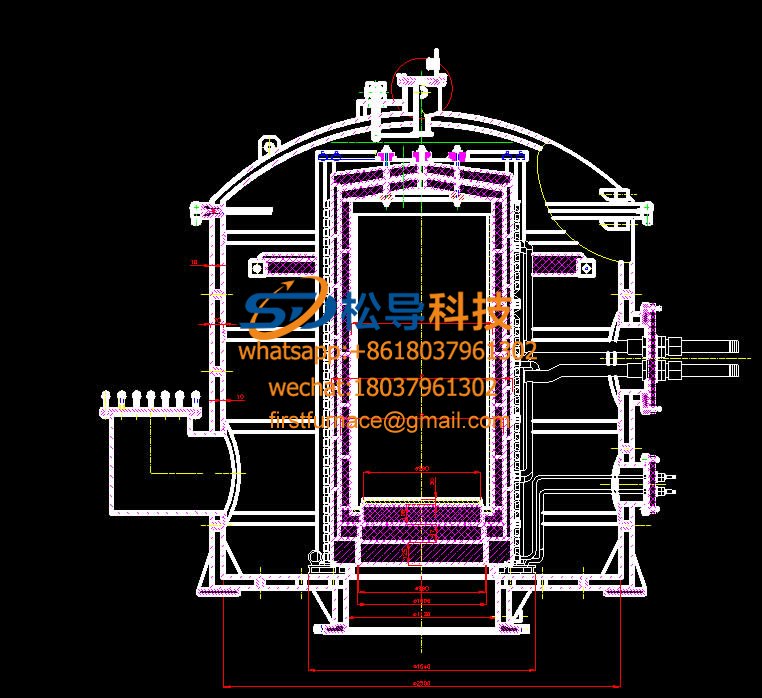

Technical Drawing of Simple Layout of Intermediate Frequency  Molybdenum wire molybdenum block sintering furnace structure

Molybdenum wire molybdenum block sintering furnace structure  Plane Layout of Intermediate Frequency Induction Heating Furn

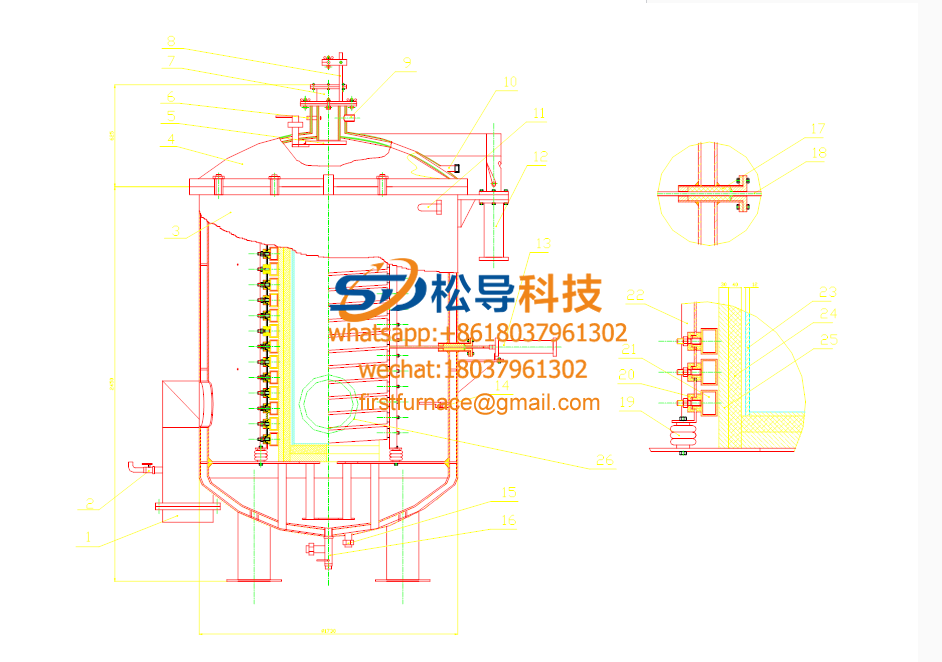

Plane Layout of Intermediate Frequency Induction Heating Furn Medium frequency sintering furnace structure schematic

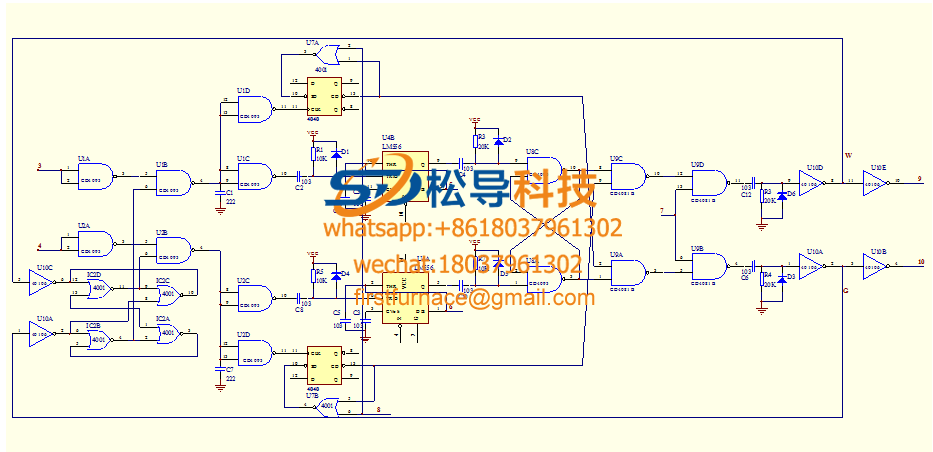

Medium frequency sintering furnace structure schematic Series intermediate frequency furnace triggering electrical s

Series intermediate frequency furnace triggering electrical sFirst, 200KG medium frequency melting aluminum furnace technical specifications and requirements:

1) , smelting material: waste aluminum material, the primary capacity is less than 10-200 kg.

2) , smelting : melting temperature of 1300 degrees, melting time of 50-60 minutes.

3) , 坩埚: silicon carbide crucible (outer high wall thickness 300mm upper mouth outer diameter 220mm) service life 70-80 times.

Second, 200KG medium frequency melting aluminum furnace technology solutions and equipment selection

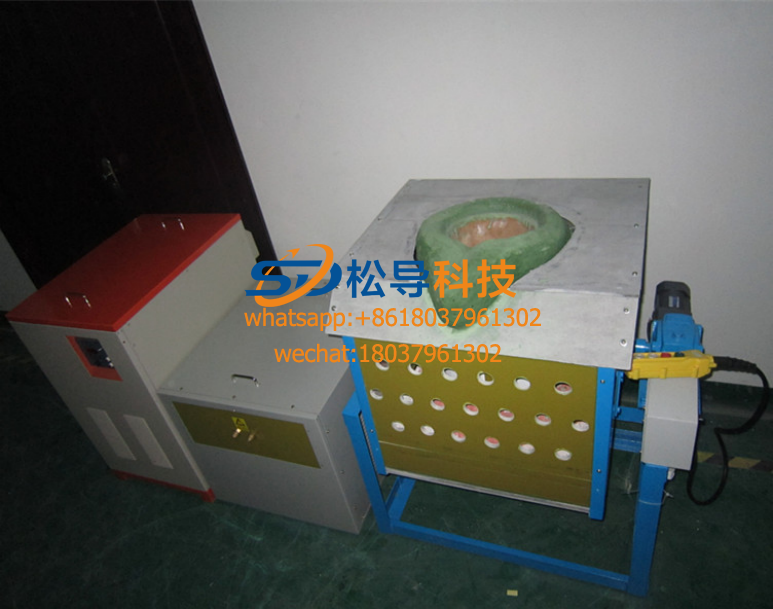

According to the technical requirements of the purchaser, the 200KG medium frequency melting aluminum furnace TXZ-160KW can be selected . The process is as follows:

1. The metal material is manually placed in the crucible of the dumping furnace .

2. After the metal is melted into a liquid, the furnace body is electrically controlled and the liquid is poured into the mold.

Third , 200KG medium frequency aluminum melting furnace TXZ-160kw quotation: ¥ 70000 yuan (excluding circulating cooling system)

1, the frequency induction heating machine (including power capacitors + box + 200 kg aluminum melting furnace electric overturned)

Fourth, the picture reference description: IF power supply + compensation capacitor + electric dumping furnace

V. Main technical parameters of T XZ- 1 6 0 kw 200KG medium frequency melting aluminum furnace:

1, the maximum input power : 160 KW

2 , the output current 40-200 A

3, the output voltage: 70-550V ,

4, oscillation frequency : 1-20KHZ

5, input power : three-phase 380V ± 20% , 50 or 60HZ

6 , input power supply air requirements: 3 × 40 0A

7 , power supply volume (CM) : 47 wide × 95 high 85 long

8 , power weight: 135 KG

9 , load continuation rate : 100% 24 hours, continuous work

1 0, input power supply air requirements: 3 × 150A

11. Requirements for cooling water of medium frequency complete furnace: ≥0. 3 Mpa , ≥2 5 /Min

12. Medium frequency power supply cooling water requirements: ≥ 0.2Mpa ≥ 8 Min

13, power waterway: one into the water, three water

Sixth, equipment standard configuration:

TX Z - 160kw high frequency induction heater configuration list | ||||

Serial number | name | unit | Quantity | Remarks |

1 | Intermediate frequency power supply | station | 1 | Standard |

2 | Capacitor compensation box | station | 1 | Standard |

3 | Aluminum melting 200kgelectric overturningfurnace body | station | 1 | Standard |

4 | Split connection cable | One | 1 | Standard |

5 | Output water cooled cable | set | 1 | Standard |

6 | control box | One | 1 | Standard |

Seven, customer self- installed machine accessories ( circulation cooling system ) :

1. Three-phase air switch 400A One

2. Power connection flexible cable 90 mm2 a few meters

3 . Cooling tower 30 tons 1;

4. Pump 3.0kw/head 30-50 meters 1 set;

5, equipment inlet and outlet water pipes: high pressure enhanced water pipe outer diameter 16 mm, inner diameter 12 mm several meters

6, water pump inlet and outlet water pipe: 1 inch (inner diameter 25 mm) within the wire high pressure reinforced pipe several meters

Eight, 200KG intermediate frequency melting furnace using the procedure:

1, electrical connection: access to a dedicated power supply line, respectively, three-phase air switch. Then connect the ground wire. ( Note that the three-phase electric power should be able to meet the use of the equipment, and the wire thickness should be used according to the instructions )

2, water: (depending on continuous working time and workload) select the cooling water system to achieve water circulation cooling.

3, through the water: open the waterway, and check the equipment every water to see if there is water outflow, the flow and pressure is normal .

4, power: first open the control power switch , then open the air switch behind the machine, and then turn on the power switch on the control panel.

5. Startup: The heating power potentiometer should be adjusted to the minimum before starting the first furnace. After the start, the temperature should be adjusted to the required power. Press the start button to start the machine. At this time, the heating indicator on the panel lights up, and the prompt sound of normal operation and the work light flash simultaneously.

6. Observation and temperature measurement: During the heating process, it is mainly determined by visual means to determine when to stop heating.

7. Shutdown: Shutdown, the control device switches off first, then turn off the main power external switch, then delayed until about 1 hour after the furnace temperature down; then off equipment cooling water, heat the inside of the machine and to facilitate induction coil Heat is emitted.

8. In the area where it is easy to freeze in winter , it should be noted that after each use, compressed air should be used to blow out the water in and out of the equipment to prevent water from cracking internal fittings and water pipes inside the equipment .

Nine, customer molten aluminum smelting scene pictures:

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved