160KW Electromagnetic Heating Furnace

160KW Electromagnetic Heating Furnace 140KW Electromagnetic Heating Furnace

140KW Electromagnetic Heating Furnace 120KW frequency conversion electromagnetic heating furnace

120KW frequency conversion electromagnetic heating furnace 100kW frequency conversion electromagnetic heating furnace

100kW frequency conversion electromagnetic heating furnace 80kW frequency conversion electromagnetic heating furnace

80kW frequency conversion electromagnetic heating furnace 60kw electromagnetic heating furnace

60kw electromagnetic heating furnace 40KW electromagnetic heating furnace

40KW electromagnetic heating furnace 30KW electromagnetic heating furnace

30KW electromagnetic heating furnace 15KW electromagnetic Heating stove

15KW electromagnetic Heating stovePrinciple of electromagnetic heating heating furnace

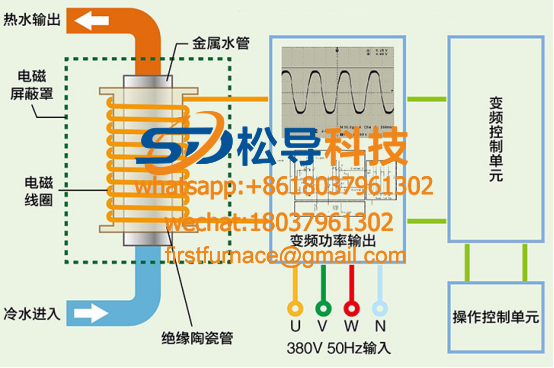

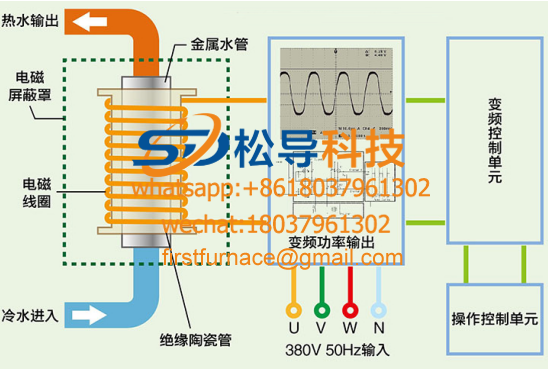

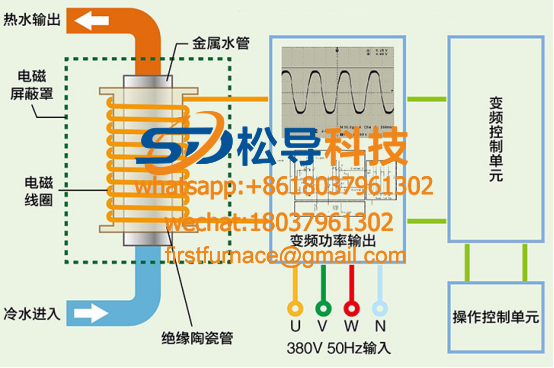

Introduction to frequency conversion electromagnetic heating furnace:

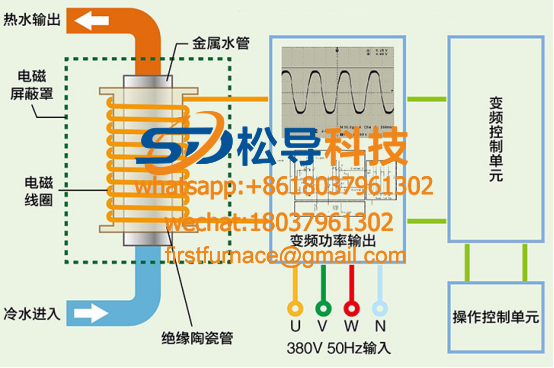

The electromagnetic heating furnace adopts the principle of electromagnetic induction heating, which uses AC rectification to convert it into DC power and then inverts it into a high-frequency alternating current, which acts on the inductor coil to generate an alternating magnetic field, so that the furnace body generates numerous small eddy currents, and the furnace is heated by eddy current collision. body, the water in the furnace body to achieve the purpose of heating, the coil has between water and thermally insulating material is greater than 20mm, but thermal efficiency can reach 98% environmentally safe, short warm-up time, fast heating. Biyuanda electromagnetic heating furnace system includes: variable frequency electromagnetic heating controller, intelligent operation control system, electromagnetic coil, heating furnace body and protection circuit.

10- 480 kW electromagnetic heating stove substantially selection table

Electromagnetic heating stove product selection table | ||||||||||||||||||||||

Model item | unit | SD -10kW | SD -12kW | SD - 80kW | SD1 -20kW | SD1 -30kW | SD1 -40kW | |||||||||||||||

rated power | kW | 10kW | 12kW | 80kW | 20kW | 30kW | 40kW | |||||||||||||||

Rated current | A | 15 | 18.2 | 27.2 | 36.3 | 45.4 | 60.8 | |||||||||||||||

Supply voltage /frequency | V/Hz | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | |||||||||||||||

Power line cross-sectional area | Mm2 | ≥4 | ≥4 | ≥6 | ≥10 | ≥10 | ≥16 | |||||||||||||||

Electrical protection level | IP | 33 | 33 | 33 | 33 | 33 | 33 | |||||||||||||||

Thermal conversion efficiency | % | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | |||||||||||||||

Shell heat dissipation | % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |||||||||||||||

Heating system maximum capacity | L | 185 | 222 | 278 | 370 | 555 | 740 | |||||||||||||||

Heating system maximum pressure | Mpa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |||||||||||||||

Pump with minimum flow | L/min | 16 | 20 | 25 | 32 | 50 | 67 | |||||||||||||||

Expansion tank capacity | L | 10 | 12 | 15 | 20 | 30 | 40 | |||||||||||||||

Heating maximum temperature | °C | 90 | 90 | 90 | 90 | 90 | 90 | |||||||||||||||

Low temperature protection temperature | °C | 5 | 5 | 5 | 5 | 5 | 5 | |||||||||||||||

Hot water yield 65 °C | L/min | 3.25 | 3.9 | 4.88 | 6.5 | 9.8 | 13 | |||||||||||||||

Dimensions | Mm | 1150*800*400 | 1150*800*400 | 1150*800*400 | 1150*800*400 | 1150*800*400 | 1800*900*400 | |||||||||||||||

Access interface | DN | 40 | 40 | 40 | 40 | 40 | 40 | |||||||||||||||

Heating area | M2 | 100-120 | 120-150 | 150-180 | 200-240 | 300-360 | 400-480 | |||||||||||||||

Heating space | M3 | 320-400 | 385-600 | 530-670 | 640-800 | 960-1200 | 1280-1600 | |||||||||||||||

Meter selection | A | 15A (60A) | 15A (60A) | 15A (60A) | 15A (60A) | 15A (60A) | 30A (100A) three phase | |||||||||||||||

Model item | unit | SD -50kW | SD - 80kW | SD -70kW | SD -80kW | SD -100kW | XHY -CN-120kW | SD -140kW | ||||||||||||||

rated power | kW | 50kW | 80kW | 70kW | 80kW | 100kW | 120kW | 140kW | ||||||||||||||

Rated current | A | 75 | 90 | 105 | 120 | 150 | 180 | 210 | ||||||||||||||

Supply voltage /frequency | V/Hz | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | ||||||||||||||

Power line cross-sectional area | Mm2 | 3×25 | 3×25 | 3×25 | 3×35 | 3×35 | 3×50 | 3×50 | ||||||||||||||

Electrical protection level | IP | 33 | 33 | 33 | 33 | 33 | 33 | 33 | ||||||||||||||

Thermal conversion efficiency | % | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | ||||||||||||||

Shell heat dissipation | % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ||||||||||||||

Heating system maximum capacity | L | 920 | 1100 | 1290 | 1480 | 1840 | 2200 | 2576 | ||||||||||||||

Heating system maximum pressure | Mpa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | ||||||||||||||

Pump with minimum flow | L/min | 60 | 72 | 84 | 96 | 120 | 144 | 168 | ||||||||||||||

Expansion tank capacity | L | 50 | 60 | 70 | 80 | 100 | 120 | 140 | ||||||||||||||

Heating maximum temperature | °C | 90 | 90 | 90 | 90 | 90 | 90 | 90 | ||||||||||||||

Low temperature protection temperature | °C | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||||||||||||||

Hot water yield 65 ° C | L/min | 16.25 | 19.5 | 22.75 | 26 | 32.5 | 39 | 45.5 | ||||||||||||||

Dimensions | Mm | 1800*900*400 | 1800*900*400 | 1800*900*400 | 1800*900*400 | 1800*900*400 | 1800*900*400 | 1800*900*400 | ||||||||||||||

Access interface | DN | 40 | 40 | 40 | 40 | 40 | 40 | 40 | ||||||||||||||

Heating area | M2 | 500-600 | 600-700 | 700-800 | 800-900 | 1000-1300 | 1200-1500 | 1400-1800 | ||||||||||||||

Heating space | M3 | 1720-2390 | 2100-2850 | 2580-3560 | 1460-1810 | 3450-4780 | 4150-5740 | 5150-7100 | ||||||||||||||

Meter selection | A | 30A (100A)three phase | Need professional electrician to install transformers reasonably, three-phase electric meter 1.5-6A | |||||||||||||||||||

Model item | unit | XHY -CN-1 80kW | SD -180kW | SD -210kW | XHY -CN-240kW | SD -3 80kW | SD -480kW | |||||||||||||||

rated power | kW | 1 80kW | 180kW | 210kW | 240kW | 3 80kW | 480kW | |||||||||||||||

Rated current | A | 240 | 270 | 315 | 360 | 540 | 720 | |||||||||||||||

Supply voltage/ frequency | V/Hz | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | |||||||||||||||

Power line cross-sectional area | Mm2 | 3×75 | 3×75 | 3×75 | 3×95 | 3×120 | 3×180 | |||||||||||||||

Electrical protection level | IP | 33 | 33 | 33 | 33 | 33 | 33 | |||||||||||||||

Thermal conversion efficiency | % | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 | |||||||||||||||

Shell heat dissipation | % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |||||||||||||||

Heating system maximum capacity | L | 2960 | 3300 | 3870 | 4400 | 6600 | 8800 | |||||||||||||||

Heating system maximum pressure | Mpa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |||||||||||||||

Pump with minimum flow | L/min | 192 | 216 | 252 | 288 | 432 | 576 | |||||||||||||||

Expansion tank capacity | L | 160 | 180 | 210 | 240 | 360 | 480 | |||||||||||||||

Heating maximum temperature | °C | 90 | 90 | 90 | 90 | 90 | 90 | |||||||||||||||

Low temperature protection temperature | °C | 5 | 5 | 5 | 5 | 5 | 5 | |||||||||||||||

Hot water yield 65 ° C | L/min | 52 | 58.5 | 68.25 | 78 | 117 | 156 | |||||||||||||||

Dimensions | Mm | 1800*900*400 | 1800*900*750 | 1800*900*750 | 1800*900*750 | 1800*900*750 | 1800*900*750 | |||||||||||||||

Access interface | DN | 40 | 80 | 80 | 80 | 80 | 80 | |||||||||||||||

Heating area | M2 | 1600-2000 | 1800-2200 | 2100-2500 | 2400-3000 | 3600-4300 | 4800-5500 | |||||||||||||||

Heating space | M3 | 2920-3620 | 6300-8550 | 7750-10700 | 8300-11480 | 12450-17220 | 16600-22960 | |||||||||||||||

Meter selection | A | Need professional electrician to install transformers reasonably, three-phase electric meter 1.5-6A | ||||||||||||||||||||

Advantages of electromagnetic heating furnace

1 , high heat conversion rate

Using electromagnetic induction heating technology, high-frequency electromagnetic eddy current heating, heat conversion rate of up to 98% , can drive the radiator. The floor heating pipe dissipates heat, the heating rate is extremely high, and the efficient and quick 1-3 minutes outlet temperature reaches 60degrees.

2 , energy saving and environmental protection

Electromagnetic induction heating is more than 30% energy saving than ordinary resistance heating . It responds to the national “ coal to electricity ” blue sky environmental protection policy, cleansing electric energy, and truly achieves zero emissions and zero pollution.

3 , electromagnetic heating truly achieve the separation of water and electricity, avoid the safety hazards of ordinary electric boilers, product constant power, soft start control, start no current impact, and have over-current, dry burning, over-temperature and other early warning functions, use more Safety.

4 , intelligent temperature control

Support PLC programmable operation, support RS485 communication, human-machine interface interaction, remote WIFI remote control using microcomputer programmable controller control, power, water temperature controllable, timed temperature, convenient and convenient.

5 , stable quality and long service life

The heating element of the electromagnetic heating furnace does not heat up, but the furnace itself is rapidly heated, which greatly prolongs the service life of the heating element, and the overall design life is 50 years.

6 , low operating costs

Electromagnetic heating has high efficiency, fast heating and no scaling. Maintenance free. Set your own heating time, temperature standards, and operating costs yourself. Greatly reduced operating costs.

7 , easy to install, practical and convenient

The refined design, butt access, water outlet, the user's original radiator, water heater, floor heating pipe, no need to replace, can be connected to run. When you turn it on, customers can set it according to their needs. The machine automatically remembers the memory, and each time it is started, it will be set according to the memory, and the intelligent automatic constant temperature operation

8 , healthy and comfortable

Frequency conversion electromagnetic induction heating heating, fast heating, high thermal efficiency, good thermal stability, air is not dry, air is more comfortable, no air conditioning disease caused by microorganisms generated by air conditioning, improved outdoor temperature is low, air conditioning heating does not work, up to Less than ideal heating effect

9 , small size

The electromagnetic heating furnace is small in size and beautiful in appearance. It can be installed in the living room, bedroom, office and other places. Minimize the possession of space.

10 , a wide range of applications

Electromagnetic heating furnaces have a wide range of applications. They can be used for central heating or household heating. From residential quarters to self-built houses, from enterprises and institutions to ordinary shops, all places that require heating, such as hotels, schools, units, and houses, are involved.

Operating cost of electromagnetic induction heating furnace

Electromagnetic heating operation cost calculation

The electricity heating operation cost of one square meter in the whole heating period can be calculated according to the following formula:

Unit area heat load × heat load coefficient × daily working time × heating period days × electricity price unit price = heating cost per unit area of the entire heating period

Electromagnetic heating operation status can be divided into the following types:

( 1 ), the user is at home for a long time, the electric heating furnace is running 24 hours a day, in order to save operating costs, the heating temperature at night is appropriately lowered.

The cost of electromagnetic heating is: 0.05kw/m2×0.6×10 hours ×120 days ×0.52 yuan / degree= 18.72 yuan / M2

( 2 ), office workers, users only at noon, at home at night, electric heating furnace intermittent operation in 3 periods.

The electromagnetic heating cost is: 0.05kw/ M2 × 0.6 × 6 hours × 120 days × 0.52 yuan / degree = 11.23 yuan / M2

( 3 ), office, 5- day work system, heating only from Monday to Friday, electric heating stove running during the day, the rest of the time running in anti-freeze state.

The electromagnetic heating cost is: 0.06kw/ M2 × 0.6 × 6 hours × ( 120 days × 5 / 7 ) × 0.52 yuan / degree = 9.62 yuan / M2

( 4 ), the school, in addition to the five- day work week , there is a 35- day holiday, heating time is relatively short.

The electromagnetic heating cost is: 0.06kw/ M2 × 0.6 × 6 hours × [ ( 120 days - 35 days) ×5/7×0.52 yuan / degree = 6.81 yuan / M2

Using the above calculated value × actual heating area (saleable area) of the room, it is possible to calculate the operating cost of the entire heating period. If the user reasonably adjusts or closes the heating device that does not require a heating room (such as an unused room, bathroom or kitchen), the actual The heating area is reduced accordingly, and the heating costs are reduced accordingly.

Note: 0.07kw/ M2 is a standard energy-efficient building requiring winter heating electric load of 55 - 70w / M2 , electromagnetic heating is more than 35% energy saving than ordinary electric heating , 0.52 yuan / kW is the current unit price of electricity in Beijing. If the peak and valley electricity price can be calculated at an average of 0.35 yuan / kWh, the user's heating cost for a long time at home is 12.6 yuan, and the heat load coefficient of 0.6 means the initial period of the heating period. At the end of the period, the indoor heat load is small, and during the coldest period of the heating period, the indoor heat load is large, with an average of 0.6 . Actual heating area: The building area is multiplied by 0.78 , minus the practical area of the room without heating.

The electromagnetic heating furnace is similar to electric water heaters and air conditioners. The working time is proportional to the heat load demand of the room. The electricity price per unit, heating cycle and electric heating furnace work time are different in each region, such as the northeast region. The weather is cold, but his house insulation measures are better (the wall thickness is 0.5 meters, the external insulation material, the window is double-vacuum glass), and the electricity bill is relatively cheap.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved