Full bridge 10KW electromagnetic heater

Full bridge 10KW electromagnetic heater Full bridge 5 KW-8KW electromagnetic heater

Full bridge 5 KW-8KW electromagnetic heater Electromagnetic induction heater

Electromagnetic induction heater 60KW electromagnetic induction heater

60KW electromagnetic induction heater 50KW electromagnetic induction heater

50KW electromagnetic induction heater 40KW Electromagnetic Induction Heater

40KW Electromagnetic Induction Heater 20KW electromagnetic induction heater

20KW electromagnetic induction heater 15KW electromagnetic induction heater

15KW electromagnetic induction heater  10KW electromagnetic induction heater

10KW electromagnetic induction heater 5KW electromagnetic induction heater

5KW electromagnetic induction heater  3KW electromagnetic induction heater

3KW electromagnetic induction heater 2.5KW electromagnetic induction heater

2.5KW electromagnetic induction heaterFirst, product electrical specifications

1 , rated voltage frequency: AC 380V/50Hz

2 , voltage adaptation range: 310V ~ 450V

3 , rated power: 60KW ( power adjustable range is 20 ~ 100%)

Second, the environmental adaptability

1 , temperature: -20 ° C ~ 50 ° C;

2 , humidity: ≤ 95%

Third, 60KW electromagnetic heater basic selection method

1 , voltage and power characteristics: 310 ~ 450V constant power output;

2 , thermal efficiency ≥ 95% ;

3 , IGBT overheat protection temperature: 85 ± 5 °C;

4 , working frequency: 5 ~ 40KHz ;

5 , using industrial grade high reliability AVR microcontroller, industrial grade high stability full bridge control technology, suitable for various commercial / industrial applications;

6 , using the third generation digital processing platform, embedded 32 -bit processing system, all digital phase shift PWM modulation technology, IGBT module works in zero voltage turn-on, zero current off state, effectively reducing the impact and loss of IGBT modules, The protection speed is faster, the equipment is more stable, and the revolutionary solution has long plagued users' problems of frying modules;

7 , digital stepless adjustment to achieve power 20% ~ 100% linear adjustable, and is also compatible with 0 ~ 5VDC and 4 ~ 20mA analog PID control power output, to ensure more accurate temperature control;

8. Add RS485 communication interface and adopt modbus RTU efficient data transmission technology to realize remote centralized control and management of controllers, which can meet the higher level requirements and needs of customers;

9. Add two load temperature detection interfaces, connect the thermistor, and detect the temperature range from 0 to 150 °C with an accuracy of ± 1 °C;

10. With open application platform, users can automatically measure important parameters such as working frequency, input current, coil output current, IGBT temperature, PWM phase difference, etc. through digital programming display . It can also be installed according to various application parameters of equipment. Debugging, even can directly do secondary development and application (for specific setting operation, please refer to the digital programming display operation instructions);

11 , with fully electrically isolated soft start heating / stop mode control interface, easy to connect with the thermostat control, start and power rise time < 1S , faster than the peer;

12 、Using 4 high-power bearing fans for heat dissipation ( 2 blowers, 2 suctions), the heat dissipation effect is stronger, the equipment operation is more stable and safer, and the customer can also choose the controller of air-cooling heat dissipation mode;

13 , with heating coil short circuit, open circuit, power phase loss, overheating, overcurrent, overvoltage and other protection functions, 130% overload and no-load transient protection function, protection response time ≤ 2uS , more complete functions, faster protection;

14 、You can set the working time from 1 to 255 days. When the time is over, the machine will automatically stop. You need to enter the password to start the machine. The user can set and change the password arbitrarily, effectively overcoming the problem of acceptance of the project.

15. Adopt coil intelligent identification technology, automatically detect the coil parameters and adjust the output power to the rated state. The coil has wide compatibility and can be compatible with the replacement of the same model of any other company in the market;

16, anti-interference ability, high reliability electrical isolation soft start, in the same heating element can control multiple controllers simultaneously start / stop without any interference;

17. It adopts the world famous brand imported Infineon IGBT module, and is equipped with imported special IGBT module driver to ensure continuous and safe operation of the equipment for a long time;

18 , using industrial grade components, 100% high temperature aging test, to ensure continuous and reliable operation in the industrial environment of 50 °C for 24 hours, the average fault-free service life ≥ 50000Hrs ;

19 , the product factory standard: chassis, air-cooled radiator and high-power bearing cooling fan integration ( 2 hair dryer, 2 suction), display, industrial indicator with space plug, R / S soft start space plug;

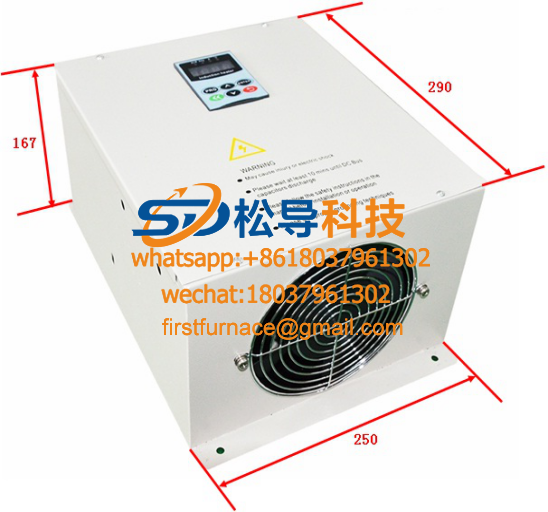

20 , controller physical size: length 600mm * width 310mm * height 250mm .

Fourth, 60KW electromagnetic heater technology advantages

1. The power supply adopts wide voltage design and constant power output of 310V to 450V , which is especially suitable for occasions where the grid voltage fluctuation is large;

2 , the original imported Infineon IGBT module digital full-bridge control technology, product quality is more stable, anti-interference ability is stronger, suitable for commercial / industrial long-term continuous work, and product startup time and control reflect faster than the peers, Temperature control is more precise;

3 , using the third generation digital processing platform, embedded 32 -bit processing system, all digital phase shift PWM modulation technology, digital stepless adjustment power 20 ~ 100% , and increased PID interface control function, input 0 ~ 5VDC and 4 ~ 20mA analog quantity control power output, making power control more accurate and stable, more suitable for production of various equipment;

4 , increase RS485 communication interface, using modbus RTU efficient data transmission technology, can achieve remote centralized control and management of controllers, to meet the higher level requirements and needs of customers;

5 , with digital programming display can automatically measure the working frequency, input current, coil output current, IGBT temperature, PWM phase difference and other important parameters, can also set the working time and password lock, that is, the time to the controller automatically stop working, you must enter the password Can be restarted, especially suitable for electromagnetic heating energy-saving transformation and promotion, in order to prevent difficulties in collection and disputes;

6. The product adopts an open application platform. The customer can program various parameters of the display device, which is more suitable for the supporting production of various equipments, and the secondary development and application of the system;

7 , with heating coil short circuit and open circuit protection, power phase loss, overheating, overcurrent, overvoltage and other perfect protection functions, to ensure that the product does not burn the board for a long time, the function is more complete, the protection speed is faster;

8. Adopt coil intelligent identification technology to automatically detect the coil parameters and adjust the output power to the rated state. The coil has wide compatibility and can be compatible with the replacement of the same model of any other company on the market;

9. It adopts 4 high-power bearing cooling fans ( 2 in 2 out structure), the heat dissipation effect is stronger, the equipment operation is more stable and safer, and the service life of the equipment is effectively guaranteed;

10 , the introduction of advanced production technology in Japan, the product has undergone rigorous functional testing and high temperature aging test before leaving the factory to ensure that the product is continuously and reliably operated in the industrial environment of 50 °C for 24 hours, the service life is ≥ 50000Hrs ; all products are guaranteed for one year nationwide , the product Lifelong maintenance, full technical guidance and service, so that you have no worries;

Five, 60KW electromagnetic heater use method

1. An indicator light is always on during normal operation. When the indicator is in the stop or protection state, the work indicator is flashing;

2 , R / S is the soft start interface, this terminal is used to control the start / stop, when it is closed, it is working; when it is off, it is stopped.

3 , three-phase electric R , S , T is 380V power input, L1 and L2 are output terminals connected to heating coil (such as controller wiring diagram).

4 , coil reference parameters:

Mica wrapped glass fiber braided high temperature resistant cable, cross-section national standard 35mm 2 or double 16mm 2 and wound, inductance is 100 ~ 120uH , length required: 35 ~ 40m (excluding lead length), thickness required after insulation cotton compression Approx.: tubular coil 20 ~ 30mm , flat coil: 10 ~15mm , rated working current: 85 ~ 90A , frequency: 10K ~ 20KHZ

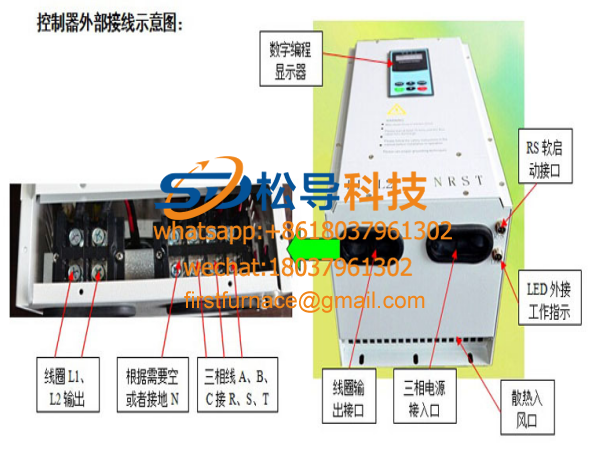

Controller installation dimension drawing:

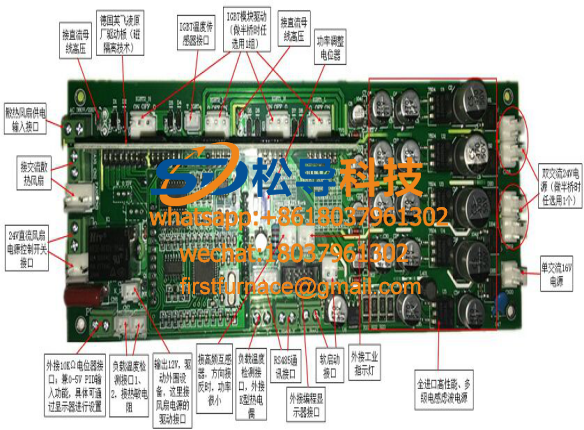

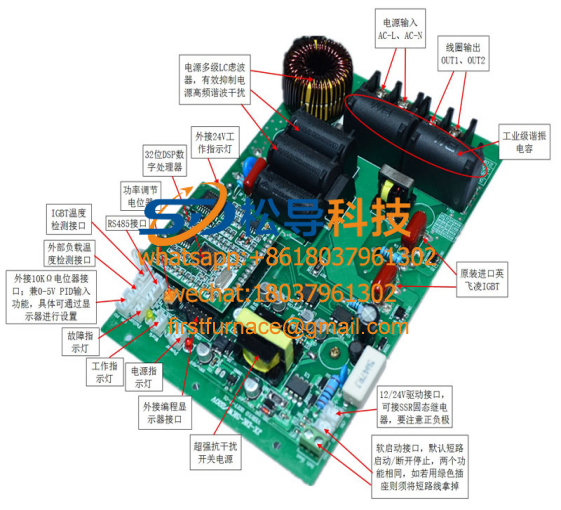

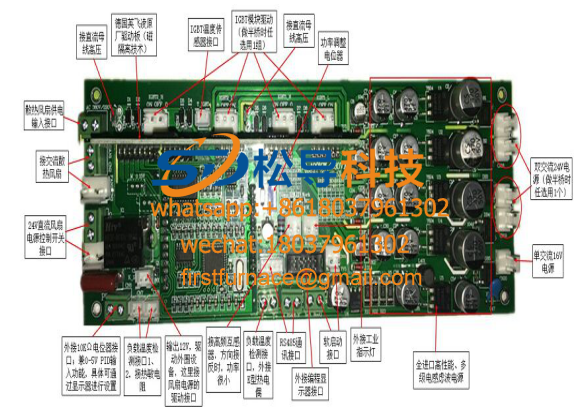

Controller internal control board wiring diagram:

Sixth, the scope of application of the product:

1. Rubber and plastics industry: various processing equipment such as injection molding machine, film blowing machine, extruder, granulator, blow molding machine, wire drawing machine, plastic dryer, rubber deoiling tank, etc.

2 , chemical industry: reaction kettle, vulcanizing machine, various wax processing, etc.

3 , food industry: tea machinery, roasted seeds and nuts machine, pancake machine, spring roll machine, bean machine, braised pork pot, etc.

4 , oilfield and other refining industry: oil pipeline heating and repair, lubricant refining, etc.

5. Medical, pharmaceutical and health industries: steam boilers, pharmaceutical heaters, medical equipment, etc.

6 , boilers: heat transfer oil boilers, hot water boilers, heating boilers, ironing boilers, etc.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved