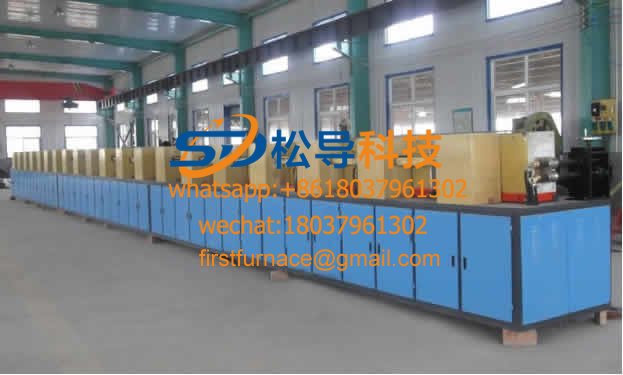

Induction heater for billet heating

Induction heater for billet heating Hot rolled billet induction heating equipment

Hot rolled billet induction heating equipment Inline induction billet heater

Inline induction billet heater Continuous billet heating furnace

Continuous billet heating furnace Continuous casting and rolling billet warming and heating pro

Continuous casting and rolling billet warming and heating pro Continuous casting billet induction heating furnace

Continuous casting billet induction heating furnace  Steel billet rolling equipment

Steel billet rolling equipment Billet online heating equipment

Billet online heating equipment billet online heating and heating electric furnace

billet online heating and heating electric furnace Billet online heating and heating furnace

Billet online heating and heating furnace Steel billet reheating equipment

Steel billet reheating equipment Steel billet warming and temperature compensation equipment

Steel billet warming and temperature compensation equipment Steel billet hot rolling production line

Steel billet hot rolling production line Steel billet heat treatment furnace

Steel billet heat treatment furnace Steel billet continuous casting and rolling heating furnace

Steel billet continuous casting and rolling heating furnace Billet continuous casting and rolling

Billet continuous casting and rolling Steel billet heating equipment

Steel billet heating equipment Billet induction reheating

Billet induction reheating Billet induction heating equipment

Billet induction heating equipment  Billet induction heating furnace

Billet induction heating furnaceThe billet hot rolling production line adopts PLC automatic intelligent control system, with all-digital and high-depth adjustable parameters , which makes your billet online heating equipment control handy .

Billet hot rolling production line parameter summary table

Billet size | Billet length | Heating temperature | Production capacity |

60 × 60mm | 3m-4m | 1150 | 25T/H |

75 × 75mm | 3m-4m | 1150 | 25T/H |

100 × 100mm | 2m | 1150 | 7T/H |

120 × 120mm | 1150 | 30T/H | |

120 × 120mm | 11.5-12.5m | 1150 | 90T/H |

125 × 125mm | 6m | 1150 | 8T/H |

125 × 125mm | 2m | 1150 | 7T/H |

130 × 130mm | 6m | 1150 | 50T/H |

135 × 135mm | 6m | 1150 | 100T/H |

150 × 150mm | 11.5-12.5m | 1150 | 70T/H |

Steel billet hot rolling production line product implementation standards:

1.JB/T4086-85 "Technical Conditions for Electronic Control Equipment for Medium Frequency Induction Heating"

2.GB/T10067.3-2005 "Basic technical conditions of electric heating equipment · Induction electric heating equipment"

3.GB/T10063.3-88 "Test methods for electric heating equipment"

4.GB/T5959.3-88 "Electric heating equipment safety"

Steel billet hot rolling production line process parameters and process requirements:

1, apparatus name: slab hot-rolling line, Billet heating apparatus, the slab induction heating equipment

2 , steel material: Q235q , Q345q , Q245R , A32 , D32 , A36 , D36, etc.

3 , billet size range: ( 6mm × 6mm ) - ( 500mm × 500mm )

4 , billet length range: 2 meters or more

5 , the maximum bending degree of the billet before entering the furnace: according to the different types of steel, there are different degrees of curvature. What should I do if the bending degree is greater than 3mm/m before the billet enters the furnace ? The billet secondary heating equipment can meet your requirements by adjusting the size of the sensor according to the degree of bending of your steel.

6, induction of slab surface into the blast furnace and the temperature of the billet furnace temperature: according to the user need to achieve the effect we design and production, blank is heated evenly, without over-burning, no cracks, and the tensile strength of the straight line to achieve the needs of users .

6.1 Control system: The entire heating process realizes PLC automatic control, and timely displays the production records such as the heating quantity. This console is used separately, specially customized human-machine interface, highly user-friendly operation instructions, all-digital, high-depth adjustable parameters, one-button restore function, easy to operate.

6.2 Feeding and guiding system: Each axis independent motor reducer drive, set multi-axis drive, single inverter control, make multi-axis operation synchronous, the device selects well-known brand, reliable quality and stable operation. The 304 non-magnetic stainless steel guide wheel is used to keep the axial direction of the guide wheel moderately flexible to accommodate the bending within the allowable range of the billet.

6.3 The billet hot rolling production line closed-loop temperature control, the US Leitai infrared thermometer and the German Siemens S7 form a closed-loop control system, automatically adjust the power supply according to the initial temperature and feed speed of the billet into the induction heater, so that the heating temperature is before the furnace Keep it constant and the workpiece is heated evenly.

6.4 billet induction heating equipment capacitor cabinet and furnace cabinet separate design (capacitor cabinet position according to user requirements)

6.5 Power supply system: It adopts series resonance IF double-rectification 12-pulse or 24-pulse KGPS1000-1000KW single power supply for independent use or multiple power supply for parallel use. Users can use it with confidence, safe and reliable, energy saving and environmental protection, and easy to operate.

What is the use of the billet hot rolling line ?

The billet hot rolling production line is used for induction heating of billets, billets, round billets, etc. Such equipment generally has other processes behind it, such as heating steel billets and rolling them into steel bars and wire rods.

Billet hot rolling production line price

The industrial hot-rolling production line for steel billets can be divided into cold billet heating furnace and billet, continuous casting and online heating furnace according to different customer processes. The power of different equipment is different, and the workpieces to be heated by each customer are different. Therefore, the price of the equipment is not the same. When purchasing a hot billet hot rolling line , you should first locate your own demand and find a larger, professional manufacturer.

How is the billet hot rolling production line precisely temperature controlled?

Adopt two-point temperature measurement. In order to ensure the precise control of the temperature of the billet and the continuous casting billet during the heating process, an infrared thermometer is generally arranged at the inlet and the outlet. In addition, in order to make up for the time difference between the temperature measurement of the thermometer and improve the control sensitivity, a hot body detection device is installed at the inlet and the outlet of each group of furnaces, so that the heating furnace can be more sensitive and reliable in maintaining low power and high power switching without material and materials. .

How to choose the hot billet production line ?

The traditional steel rolling process is that the steel slabs obtained by steelmaking are cooled by stacking, transported to a rolling mill, and then heated by a heating furnace to be rolled into steel. This process has two drawbacks. First, the billet is pulled out from the steelmaking continuous casting machine and has a temperature of 700-900 ° C on the cold bed . The latent heat of the billet is not effectively utilized. Second, after the slab is heated by the heating furnace, the surface loss of the slab is about 1.5% due to oxidation loss . The steel-making workshop energy-saving and emission reduction technology transformation project implements continuous casting and rolling for the above problems, but the second point defect is still used in the regenerative heating furnace . In order to fully save energy, it is more suitable to use the slab hot rolling production line for on-line heating and uniform temperature heating of the continuous casting slab.

The role of steel billet hot rolling production line ?

The billet warming and heating furnace is a continuous casting billet (small billet, slab, round billet, rectangular billet) which is heated by the heating furnace before entering the rolling mill to realize continuous casting and rolling production. The heating capacity of the whole billet is heated to 1100 ° C , and the temperature uniformity is passed through the induction heating furnace to ensure that the temperature uniformity of the billet is better than the natural state before heating.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved