Aluminum forging furnace

Aluminum forging furnace Aluminum rod medium frequency heating furnace

Aluminum rod medium frequency heating furnace Aluminum induction heating furnace

Aluminum induction heating furnace Aluminum hot rolling

Aluminum hot rolling Aluminum billet heating furnace

Aluminum billet heating furnace Aluminum billet induction heater

Aluminum billet induction heater aluminum alloy induction heating equipment

aluminum alloy induction heating equipment Aluminum ingot medium frequency heating furnace

Aluminum ingot medium frequency heating furnace Aluminum ingot online heating medium frequency furnace

Aluminum ingot online heating medium frequency furnace Trapezoidal aluminum ingot heating equipment

Trapezoidal aluminum ingot heating equipment Aluminum rod online heating furnace

Aluminum rod online heating furnace aluminum rod induction heating furnace

aluminum rod induction heating furnace Aluminum bar heating furnace

Aluminum bar heating furnace aluminum rod heating equipment

aluminum rod heating equipment Aluminum rod induction heating equipment

Aluminum rod induction heating equipment Aluminum bar induction heating furnace

Aluminum bar induction heating furnace Forging aluminum

Forging aluminum Alloy aluminum heating furnace

Alloy aluminum heating furnace Induction aluminum heating

Induction aluminum heating Trapezoidal aluminum ingot heating furnace

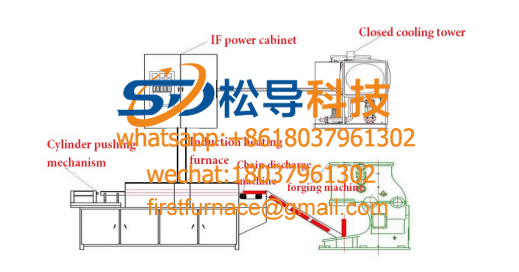

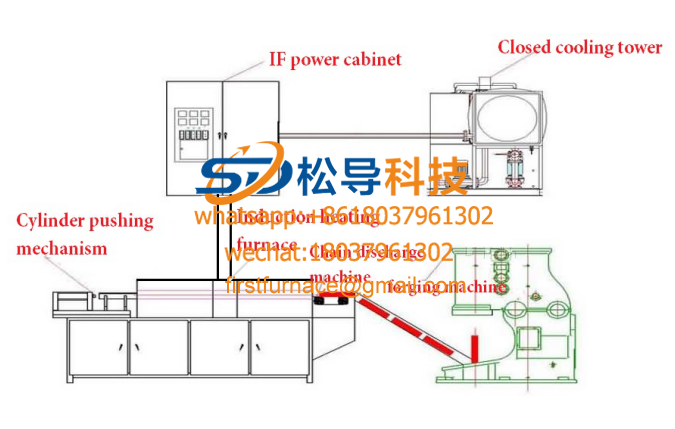

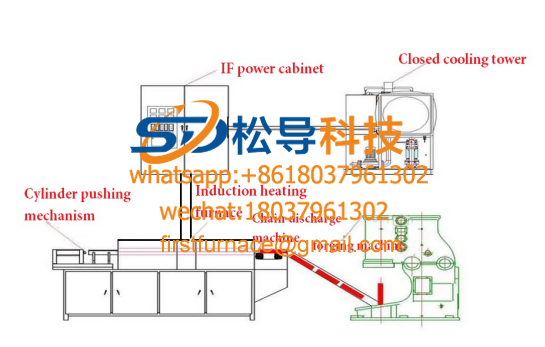

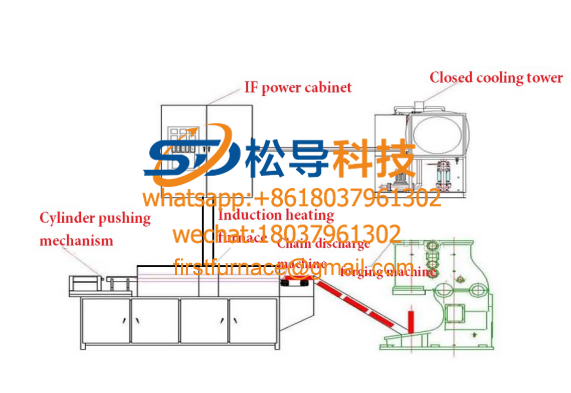

Trapezoidal aluminum ingot heating furnaceThe equipment is mainly used as an aluminum ingot heating furnace for various specifications of aluminum ingots and trapezoidal aluminum ingots. The equipment is super energy-saving series inverter. The intermediate frequency power supply is a mechatronic structure. The complete equipment includes one series inverter medium frequency power supply and one ladder. A set of induction heaters, a set of 14 -inch color touch screen computer closed-loop control system, and a set of equipment horizontal moving rails.

The equipment line for trapezoidal ingots with raised temperature, equipment rated at 3 00kw - 5 00kw, the nominal frequency of 200 - 300 HZ, online raised temperature 60- 2 50 ℃, 2350-3000 mm for a cross-sectional ingot hour yield above 5.5 T, because the device automatically adjusts the output power, the power consumption control apparatus tons 5 0kW.h / t to the; linear guide device designed at the bottom, 1.5 m laterally movable to facilitate ingots without the need Remove the device while heating.

Aluminum ingot intermediate frequency heating equipment technical parameters

A , comprehensive parameters | ||

Serial number | project | Parameter requirement |

1 | Equipment form | Series inverter intermediate frequency heating |

2 | Equipment use | For aluminum ingots and trapezoidal aluminum ingot heating |

3 | Rated power | 300kw-500kw |

4 | Maximum power | 300kw +30% |

5 | Operating temperature | 15 0 °C |

6 | Cabinet material | Stainless steel and steel structure |

7 | Mobile mode | Horizontal rail movement |

8 | Maximum range of movement | 1.5 meters |

9 | Working noise | <85 decibels |

11 | Wiring way | The wiring line |

12 | Hourly output | 5 T/h |

13 | Outlet temperature | 150 °C |

14 | Unit power consumption | ≤ 5 0kW.h/t |

15 | Adjustable frequency | Frequency adjustable 200-500hz |

17 | Fixed frequency | 250hz |

B , electrical parameters : | ||

Serial number | project | parameter |

1 | Power supply | 500kw / three phase or six phase |

2 | Number of rectifiers | 6 veins and 12 veins |

3 | Inverter | SCR series inverter |

4 | Highest frequency | 1000hz |

5 | Computer management system | Xp system management |

6 | Line voltage | 380V |

7 | Sensor voltage | 75 0V |

8 | Start success rate | 100% |

9 | Power factor | Greater than 0.9 6 |

10 | Harmonic quantity | No 5th and 7th harmonics |

C , heat exchange cooling water system parameters | ||

Serial number | project | parameter |

1 | Inlet pressure | 0.2-0.4MPa |

2 | Inlet temperature | 5-35 °C |

3 | Effluent temperature | < 4 5 °C |

Mechanical technical parameters

A , heating index | ||

Serial number | project | Trapezoidal aluminum ingot heating |

1 | structure | Steel structure |

2 | Material | A3 steel |

3 | Panel thickness | 12 mm |

4 | Sensor copper tube material | T2 pure copper 99.9 |

5 | Inductor copper tube specifications | Rectangular, 20 × 2 0 , wall thickness 3-5mm |

10 | Sensor number | By design |

11 | Sensor winding | Machine winding |

12 | waterway | 1 in 1 out |

14 | Water cooling ring material | Copper tube |

15 | Heating body shell heat | < 5 5 °C |

Serial number | project | |

1 | insulation | The coil is double-layered with mica board |

2 | bolt | Ordinary carbon steel bolts are grade 8.8 . Other bolts made of stainless steel or copper |

3 | Water connection hose | Non-flame-retardant high-insulation rubber tube |

4 | Water collector | Stainless steel |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved