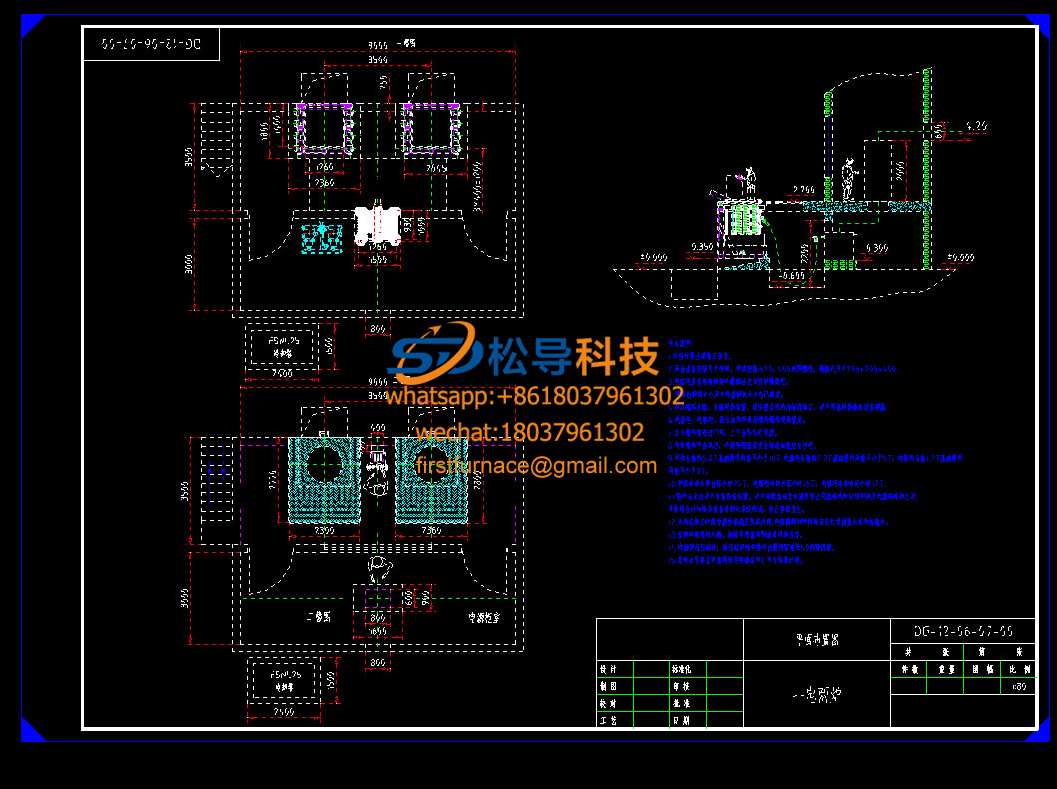

Schematic diagram of plane layout of 1 ton medium frequency i

Schematic diagram of plane layout of 1 ton medium frequency i 0.75T induction melting furnace site

0.75T induction melting furnace site 2T induction melting furnace use site

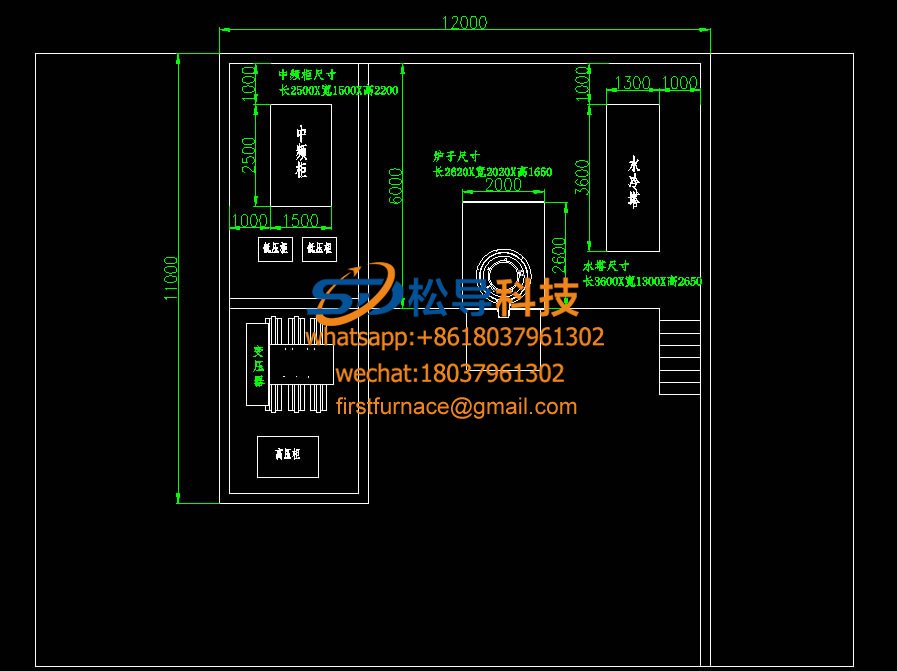

2T induction melting furnace use site 1ton induction melting furnace installation layout

1ton induction melting furnace installation layout 1T induction melting furnace technical schematic

1T induction melting furnace technical schematic 0.5t induction melting furnace schematic

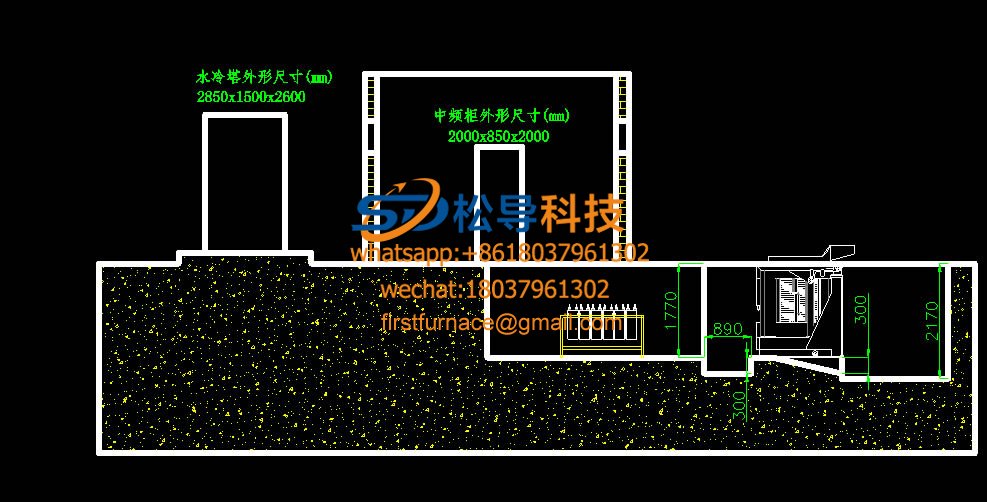

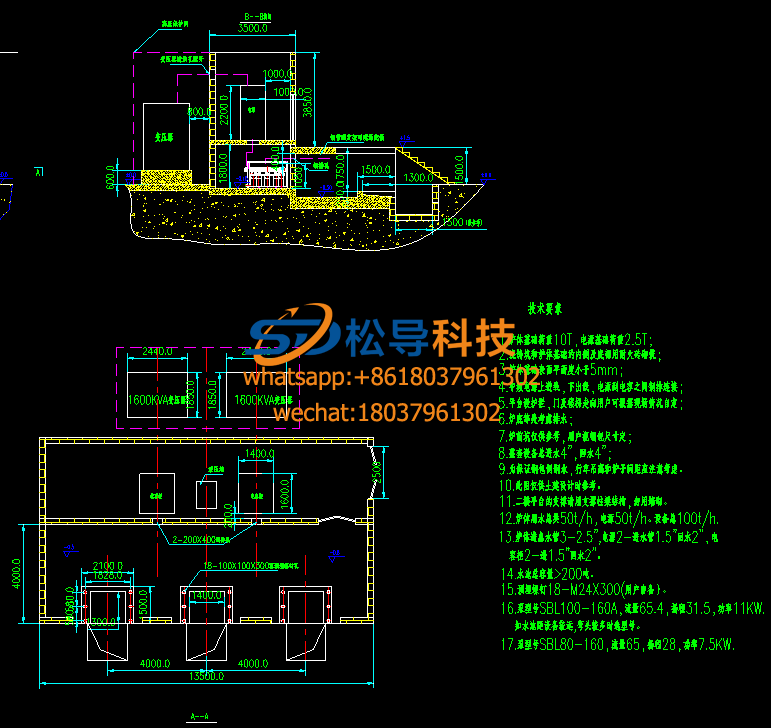

0.5t induction melting furnace schematic 1.5 tons medium frequency induction melting furnace foundati

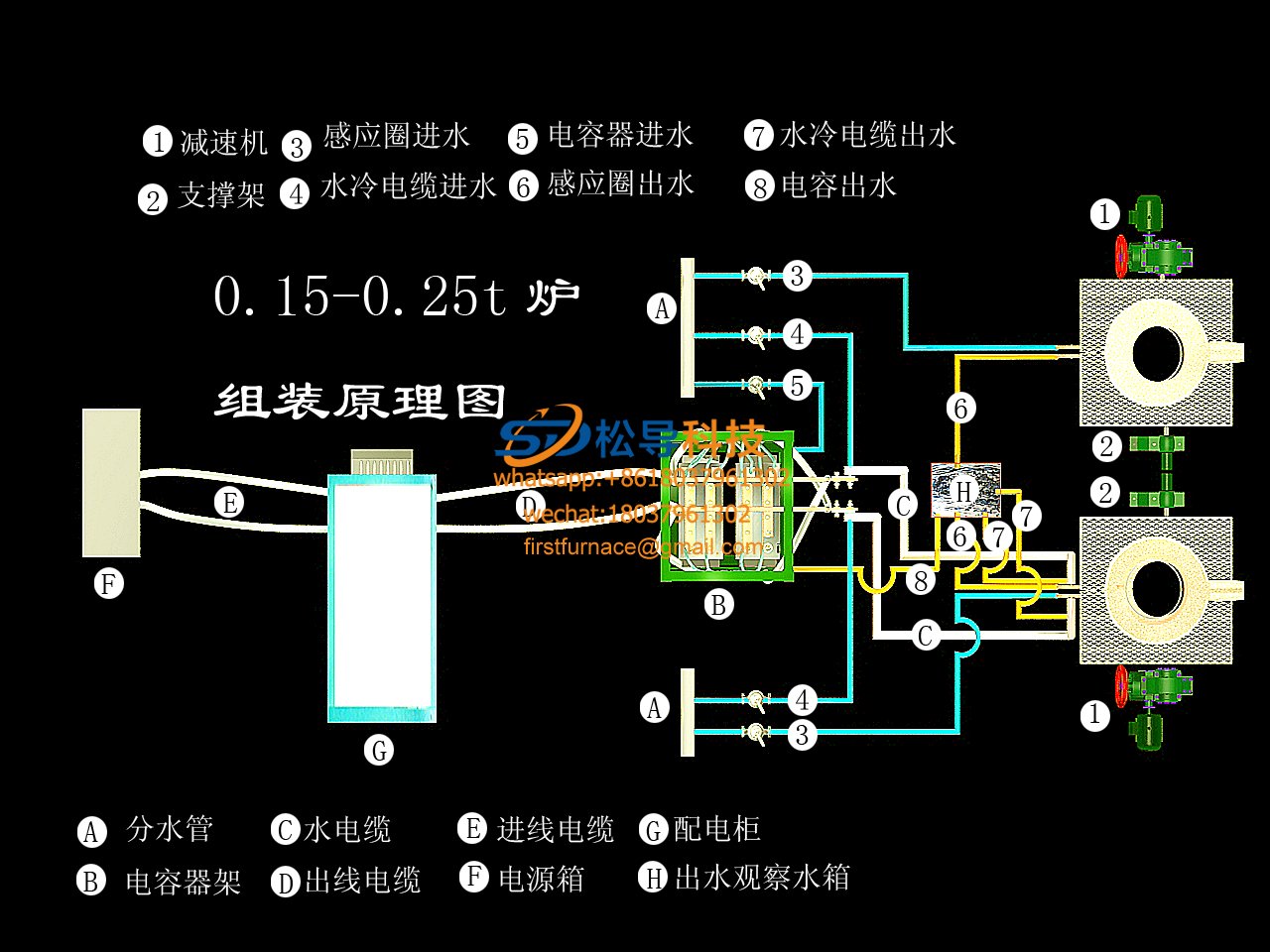

1.5 tons medium frequency induction melting furnace foundatiThe induction melting furnace consists of:

Medium frequency power supply - capacitor cabinet - aluminum shell or steel shell furnace - hydraulic tilting furnace system - remote control box - Closed loop cooling tower.

The price of induction melting furnace

The price of the induction melting furnace is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price.Firstfurnace@gmail.com

Rated capacityT | model | Rated powerKW | Price ¥ (yuan) |

250 | KGPS-250 | 250 | Total: ¥ 70500 Yuan |

0. 5 | KGPS-400 | 400 | Total: ¥ 148800 |

0.75 | KGPS- 6 00 | 600 | Total: ¥ 1 80000 |

1 | KGPS- 8 00 | 800 | Total: ¥ 221,000 |

1.5 | KGPS-1 2 00 | 1 2 00 | Total: ¥ 3,00000 |

2 | KGPS- 1600 | 1600 | Total: ¥ 361500 |

3 | KGPS- 2 000 | 2000 | Total: ¥ 447,000 |

5 | KGPS- 3 000 | 3000 | Total: ¥ 643,000 |

6 | KGPS- 3 500 | 3500 | Total: ¥ 700000 |

The choice of induction melting furnace configuration

model | Rated Capacity | rated power | frequency | Line voltage | IF output voltage | Melting time | power consumption | transformer |

T | KW | KHZ | V | V | Minutes/T | KWH/T | KVA | |

KGPS-250 | 0.25 | 250 | 1 | 380 | 750 | 65 | 680 | 300 |

KGPS-400 | 0.5 | 400 | 1 | 380 | 1600 | 65 | 680 | 400 |

KGPS-500 | 0.75 | 500 | 1 | 380 | 1600 | 65 | 650 | 600 |

KGPS-700 | 1 | 700 | 0.7 | 660 | 2400 | 60 | 640 | 800 |

KGPS-1000 | 1.5 | 1000 | 0.7 | 660 | 2400 | 60 | 640 | 1000 |

KGPS-1500 | 2 | 1500 | 0.5 | 660 | 2400 | 65 | 640 | 1500 |

KGPS-2000 | 3 | 2000 | 0.5 | 950 | 3200 | 65 | 640 | 1800 |

KGPS-3000 | 5 | 3000 | 0.5 | 950 | 3200 | 70 | 620 | 2500 |

KGPS-4000 | 6 | 4000 | 0.5 | 950 | 3600 | 70 | 600 | 3150 |

KGPS-4500 | 8 | 4500 | 0.3 | 950 | 3600 | 70 | 580 | 4000 |

the source of equipment procurement

The components of the equipment , such as SCR and rectifier bridge, use high-quality electrical components. The key components are imported high-quality components. Other components are designed according to military standards. All components are subject to strict quality inspection and aging test.

Five, induction melting furnace structure selection : IF power supply + compensation capacitor box + medium frequency induction coil

The intermediate frequency melting furnace and the like adopt this structure, and the equipment is simple, the loss is low, the work efficiency is high, and the manufacturing cost is low. In this structure, the induction coil is relatively long and is usually wound with a copper tube of 3 m to 10 m length. Since the intermediate frequency power supply is directly output, the induction coil is isolated from the main power, so the induction coil must be well insulated .

Induction melting furnace standard configuration:

Induction melting furnace configuration list | ||||

Serial number | name | unit | Quantity | Remarks |

1 | Thyristorintermediate frequency power supply | station | 1 | Standard |

2 | Capacitor compensation box | station | 1 | Standard |

3 | Electric overturning furnace | station | 1 | Standard |

4 | Split connection cable | One | 1 | Standard |

5 | Output water cooled cable | set | 1 | Standard |

6 | control box | One | 1 | Standard |

Induction melting furnace appearance structure

How to arrange the induction melting furnace? Please see the figure below for answers.

What information does the customer need to provide to the supplier before purchasing the induction melting furnace?

1. Induction melting furnace should have space for layout, and it is necessary to provide the area and layout of the plant.

2. The customer needs to provide the capacity of the transformer, the magnitude of the incoming line voltage, and the frequency of the incoming line voltage.

3. The induction melting furnace requires water-cooling equipment, and the induction melting furnace configuration contains water-cooling equipment.

4. The furnace structure of the induction melting furnace has a steel shell furnace body and an aluminum shell furnace body, and the customer needs to specify the furnace body structure.

5. The power supply of the induction melting furnace is an intermediate frequency power supply. The circuit structure of the intermediate frequency power supply is divided into an inverter parallel connection and an inverter series structure. The inverter series structure is energy-saving, the power factor is 0.98, and the line is stable. The inverter parallel structure is of the common type with a power factor of 0.92, which requires the customer to specify the line structure.

A good way to correctly and quickly select the " induction melting furnace "

1,Induction melting furnace transformer capacity selection

Selection basis: value of transformer capacity = value of induction melting furnace power supply x 1.2

The transformer is a rectifier transformer. In order to reduce the interference of harmonics, it is used as far as possible for the special plane, that is, one induction melting furnace is equipped with a rectifier transformer.

2,Induction melting furnace inlet line voltage selection

3T induction melting furnace adopts three-phase five-wire 380V , 50HZ industrial power

Selection basis: For medium frequency power supply for induction melting furnace below 1000KW , three-phase five-wire 380V , 50HZ industrial power is generally used , and for induction melting furnace above 1000KW , the focus is on using 660V incoming voltage .

3,According to the capacity requirements, determine the induction melting furnace with large tonnage.

The capacity of the induction melting furnace can be determined by the weight of the individual pieces and the weight of the molten iron required for each working day .

The standard tonnage is as follows:

250kg induction melting furnace

500kg induction melting furnace

1T induction melting furnace

2 T induction melting furnace

3T induction melting furnace

5T induction melting furnace

4. Selection of furnace structure of induction melting furnace

The capacity of the induction melting furnace is small. The recommended choice is: the furnace body of the hydraulic steel shell .

The aluminum alloy structure commonly known as the aluminum alloy structure with the reducer as the tilting furnace method. The induction melting furnace of the steel structure with the hydraulic cylinder as the tilting furnace is commonly called the steel shell furnace. The steel shell furnace is a steel structure, and the aluminum shell furnace shell material is an aluminum alloy .

11. What is the role of the yoke in the induction melting furnace ?

Providing a magnetic circuit to enhance the magnetic conduction capability, and only function as a magnetic line transmission in the magnetic circuit;

Preventing magnetic flux leakage to the outer magnetically conductive material; it can improve the melting efficiency and reduce the interference and protection.

The yoke shielding is characterized in that a yoke is made of a magnetic material and is mounted on the periphery of the induction coil, so that as many magnetic fluxes as possible form a loop through the yoke to reduce the leakage magnetic field and achieve the purpose of shielding.

In order to ensure the quality of the iron core stacking, the silicon steel column installation and production project department produces a special positioning welding and silicon steel sheet stacking platform, and the laminated assembly adopts a curved stacking process, which has a good compacting effect and less magnetic leakage. It is more close to the induction coil, improves the magnetic flux direction, eliminates the local magnetic flux saturation phenomenon of the iron core at the joint, reduces the no-load loss and no-load current of the iron core, fully utilizes the magnetic permeability area of the silicon steel sheet , and reduces the induction melting. the possibility of local heating furnace of the furnace. The contact surface of the yoke cover stainless steel plate and the silicon steel sheet is separated by a high-grade gold mica plate, the outer side is clamped by stainless steel, and a specially designed copper heat pipe is arranged between the yoke and the stainless steel plate clamp, or in a stainless steel plate. welded on the heatsink or cooling tank, the water cooling of the yoke, the yoke is to ensure that the normal state, on both sides of the yoke use of 4 - 8 stainless steel screws holding the locking bolt, to avoid elevated temperatures deformed cover More than 60 % of the surface of the induction coil effectively collects magnetic lines of force into the molten pool to prevent heat generation of the furnace shell and improve system efficiency. The performance is stable and the coil is reliably supported , which improves the overall strength of the furnace. Induction melting furnace yoke, in order to ensure the process control of the quality of the silicon steel column, the parameters of the silicon steel sheet are inspected before stacking, and each silicon steel sheet is subjected to visual inspection before stacking, and the copper sink is cooled by the water tank. both the pressure tube and the water passing through the experiments, the outer coating DuPont Dote arc-proof insulating paint, effectively prevents partial section through the magnetic silicon steel, rusty steel sheet to ensure the quality of the yoke.

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved