Bridge shell medium frequency induction heating furnace

Bridge shell medium frequency induction heating furnace Steel tube heating furnace

Steel tube heating furnace Bar intermediate frequency induction heating furnace

Bar intermediate frequency induction heating furnace 1000KW bar medium frequency induction heating furnace

1000KW bar medium frequency induction heating furnace induction metal heater

induction metal heater medium frequency induction heating machine

medium frequency induction heating machine medium frequency semi-automatic heating furnace

medium frequency semi-automatic heating furnace medium frequency induction heating furnace

medium frequency induction heating furnace medium frequency heating furnace

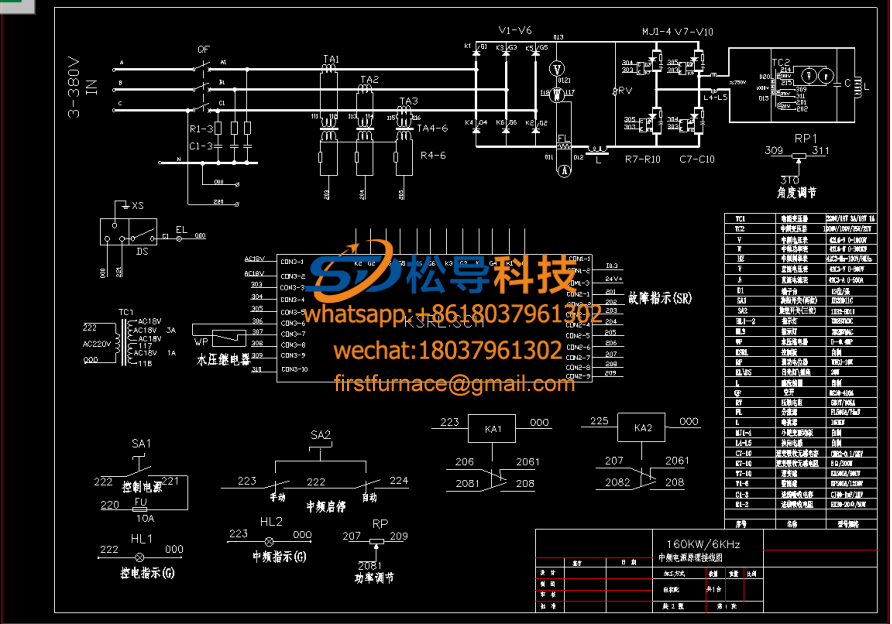

medium frequency heating furnace 160kw medium frequency induction heating furnace electrical s

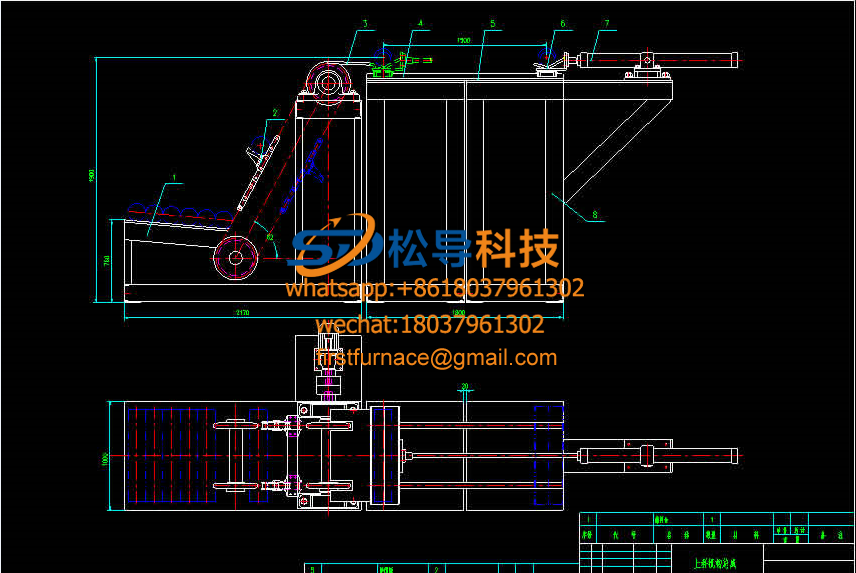

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

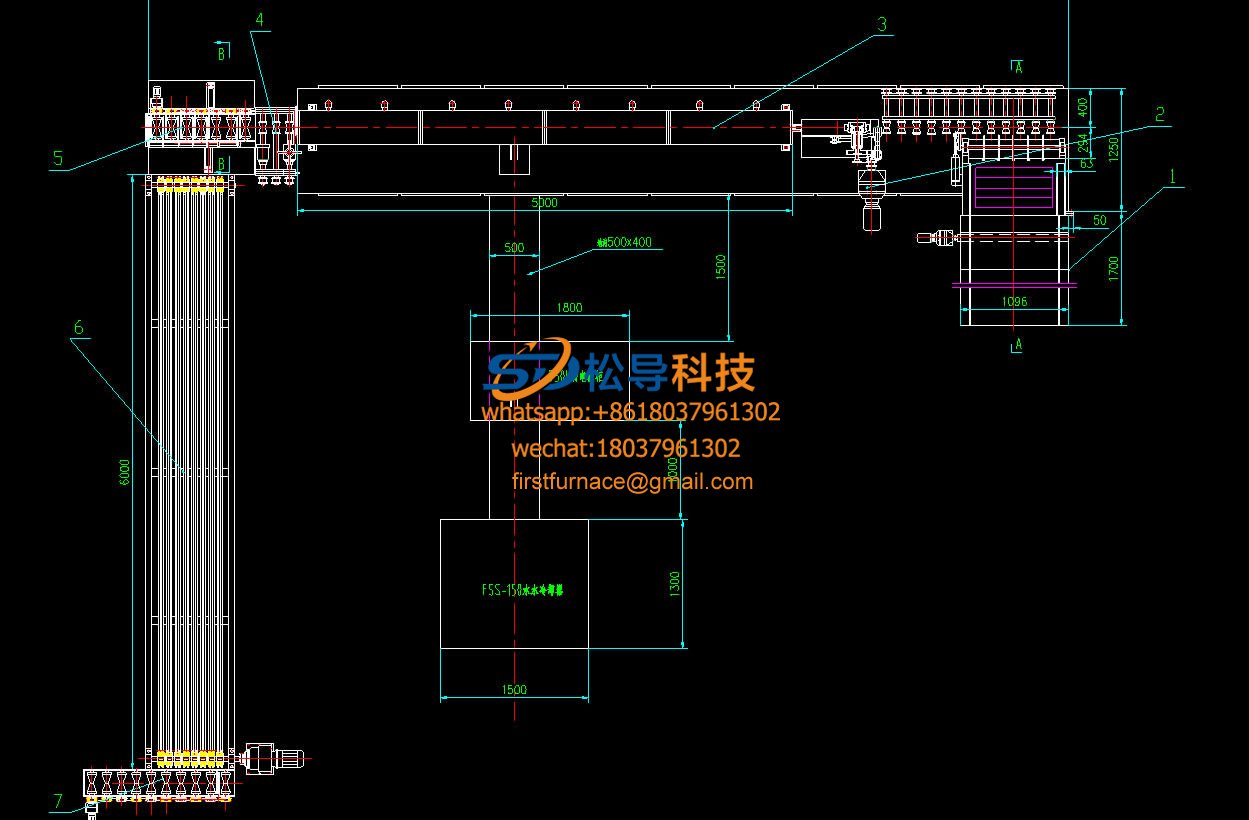

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

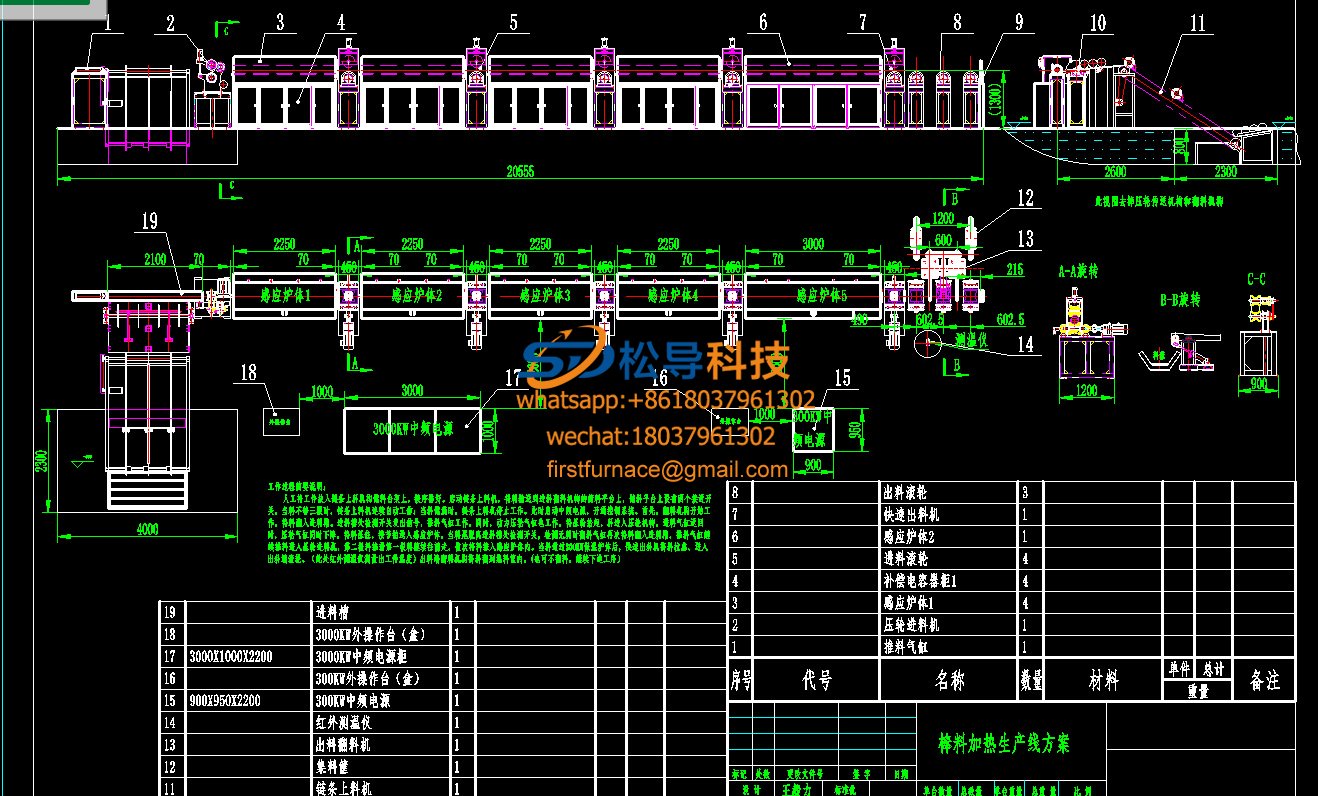

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

billet induction heating furnace coilOur company has mature design and production experience in the field of medium frequency induction furnace heat, and has provided stable and efficient products for many enterprises. The heating furnace body adopts the quick replacement method, and only the furnace body needs to be replaced when the product specifications are replaced. It takes only a few minutes to replace the furnace. All the inlet and outlet pipes of the equipment are made of stainless steel, and the pipeline is permanently anti-corrosion and anti-rust design. The equipment is a power-saving product, featuring fast heating speed, energy saving and consumption reduction, stable and reliable operation ( 24 hours continuous trouble-free operation). The service life of complete sets of equipment is designed and manufactured according to not less than 20 years, and the equipment control technology is in the leading position in the same industry within five years.

First, the composition and configuration of the intermediate frequency induction heating furnace :

The medium frequency induction heating furnace is generally composed of an intermediate frequency power source, an electric heating capacitor, an induction furnace body, an inlet and outlet transmission device, and a temperature measuring device. When fully automatic control, it also includes PLC programmable controller, man-machine interface or industrial control computer system and industrial control configuration software and various sensors.

Second, the power supply selection method of medium frequency induction heating furnace with power less than 1000KW

Medium frequency induction heating furnace parameter table with power less than 1000KW | |||||||

Rated power (KW ) | Rated frequency (HZ) | Transformer capacity (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage (V) | Power consumption (KW.h/t) | Bar diameter ( mm ) |

80 | 1000~8000 | 100 | 380v | 6 Pulse | 800 | 450 | Φ 6-35 |

100 | 1000~8000 | 160 | 380v | 6 Pulse | 800 | 450 | Φ 25-40 |

120 | 1000~8000 | 200 | 380v | 6 Pulse | 800 | 450 | Φ 30-50 |

160 | 1000~8000 | 250 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

200 | 1000~8000 | 315 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

250 | 1000~8000 | 400 | 380v | 6 Pulse | 800 | 450 | Φ 60-80 |

350 | 1000~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

400 | 500~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

500 | 500~8000 | 630 | 380v | 6 Pulse | 800 | 450 | Φ 120-150 |

1000 | 500~1000 | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

1500 | 500~1000 | 1600 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

2000 | 500~1000 | 2200 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

Third, what parameters are required for the selection of medium frequency induction heating furnace ?

The selection of medium frequency induction heating furnace generally requires the following parameters:

First: the shape of the heated workpiece, the outer dimensions, and the weight of the heated workpiece.

Second: the material material of the heated workpiece (generally induction heating, only for metal conductor materials ).

Third: the time of the target temperature required for heating the heated workpiece, and the target temperature.

Once the above three points are clear, the intermediate frequency induction heating furnace can be selected including matching power.

Fourth, what are the characteristics of the medium frequency induction heating furnace body structure?

1. Furnace structure: Our company's heating furnace is designed as an overall quick change type. Quick change is possible when changing the furnace body for different heated workpieces.

2. Furnace lining : The furnace lining adopts silicon carbide or integral knotting method, and the use temperature is above 1450 °C .

3. Protection : Automatic shutdown when the water temperature exceeds 65 °C .

4. Induction furnace water cooling rail: Water-cooled rail is installed on the induction furnace lining.

5. How to calculate the power of the medium frequency induction heating furnace ?

P=(0.168×200×693)/(0.24×0.6×145)=1029KW In the formula: 0.168—the average specific heat of the ferrous metal; 2080—the mass of the workpiece (Kg); 200—the temperature rise of the workpiece heating; 0.24— Work heat equivalent; 0.6 - average efficiency (0.6 in this case, generally 0.5 ~ 0.65, lower profile sensor, take 0.4); 145 - work beat (seconds)

According to the above calculation, a 1KHz induction heating device with a rated power of 1500 KW can be configured to meet the needs.

Sixth, the selection method of the power frequency of the medium frequency induction heating furnace ?

The choice of power frequency follows the principle of optimal heating efficiency and temperature uniformity (core temperature difference). The higher the frequency, the higher the heating efficiency, but the too high frequency is likely to cause the surface of the workpiece to be too burnt. According to our experience, the frequency is selected to be 2500KHZ. , the best heating effect can be obtained without overheating the workpiece temperature .

Seven, what are the advantages of the medium frequency induction heating furnace ?

Induction heating furnace using an induction heating and conventional flame forging forging process has obvious advantages compared:

1. The heating speed is fast, the required temperature can be reached in a very short time, the oxidation of the metal is greatly reduced, the production efficiency is high, the oxidative decarburization is less, the material and the forging die cost are saved.

Since the principle of medium frequency induction heating is electromagnetic induction, its heat is generated in the workpiece itself. The average worker can use the medium frequency electric furnace to carry out the continuous work of the forging task ten minutes after going to work. The professional workers do not need to burn the furnace and seal the furnace in advance. . There is no need to worry about the waste of the heated billet of the coal stove due to power outage or equipment failure. Because the heating method has a fast heating rate, the oxidation is extremely small, and at least 20-50 kg of steel raw materials are saved per ton of forgings compared with the coal burning furnace , and the material utilization rate can reach 95% . Since the heating method is uniform in heating and the temperature difference of the core watch is extremely small, the life of the forging die is greatly increased in forging, and the surface roughness of the forging is also less than 50 um .

2. Excellent working environment, improve workers' working environment, no pollution, low energy consumption.

Compared with coal stoves, induction heating furnaces do not produce exhaust gases such as carbon monoxide, carbon dioxide, sulfur oxides, and soot. The external radiant heat is small and the noise is low. Workers will no longer be bake and smoked in the hot coal stove. The environment is purified and the level of health is guaranteed. Induction heating is the most energy-efficient heating method in electric heating furnace. The power consumption of ton forgings heated from room temperature to 1100 °C is less than 360 degrees.

3. The heating is uniform, the temperature difference of the core meter is very small, and the temperature control precision is high.

Induction heating heat is generated in the workpiece itself, so the heating is uniform, and the temperature difference between the core and the core is extremely small. Application of temperature control system can achieve precise temperature control to improve product quality and yield.

The main equipment of the medium frequency heating forging and heat treatment workshop, the stability, reliability and safety of its work are the guarantee for the normal and stable operation of the forging and heat treatment production lines of the flow operation.

4 , easy to replace the furnace body to adapt to the different requirements of the overall heating or end heating of the bar.

5 , installation, commissioning and operation is very convenient, one will meet;

6 , ultra-small size, removable, easy to use with any equipment;

Frequency heating apparatus having a heating furnace of small size, light weight, high efficiency, excellent quality and favorable thermal processing environment, etc. are rapidly eliminated coal-fired furnace, gas furnace, oil furnace and general resistance furnace, a new generation of metal heating apparatus.

7 , energy saving and environmental protection, heating more uniform and fast, automatic feeding, greatly saving costs;

8. Induction heating does not produce an open flame, which eliminates the possibility of dangerous events such as fires and explosions, and greatly improves safety.

Eight, IF heating furnace uses:

IF heating furnace material is mainly used for metal forging, extrusion, hot rolling, and the overall shear heating before quenching a metallic material, annealing, tempering, heating metal forging, extrusion, welding, brazing heat treatment .

Common metal heating process with medium frequency induction typical temperature

Hot processing type | Carbon steel | stainless steel | copper | aluminum | titanium |

forging | 1180~1300 | 1200~1320 | 870 | 450 | 930 |

Rolling | 1230 | 1260 | 760~870 | 450~540 | 930 |

extrusion | 1230 | 1300 | 870 | 480 | 950 |

9. What are the precautions when operating the IF induction furnace ?

1. Before starting the furnace, check whether the electrical equipment, water cooling system, sensor copper tube, etc. are in good condition, otherwise it is forbidden to open the furnace.

2 , furnace furnace melting loss exceeds the provisions should be repaired in time. It is strictly forbidden to smelt in the deep melt.

3 , power transmission and furnace should be responsible for the person, after the power transmission, it is strictly prohibited to touch the sensor and cable. The shifter is not allowed to leave the post without permission, pay attention to the sensor and the external situation.

4. When loading, check whether there are any inflammable, explosive and other harmful materials in the charge. If it should be removed in time, it is forbidden to directly add cold and wet materials to the molten steel. After the molten liquid is filled to the upper part, it is strictly forbidden to add large blocks. To prevent the cover.

5. When the furnace is repaired and the crucible is made, the iron filings and iron oxides are prohibited. The crucible must be dense.

6. The pouring site and the pit in front of the furnace should be free of obstacles and no water to prevent the molten steel from falling to the ground.

7. The molten steel is not allowed to be overfilled. When the hand is raised and poured, the two should cooperate with each other. The walking should be stable. Do not rush to stop. After pouring, the surplus steel should be poured into the designated place.

8. The medium frequency generator room should be kept clean. It is forbidden to bring inflammable and explosive materials and other sundries into the room. No smoking is allowed indoors.

Ten, what are the requirements for the installation of the intermediate frequency induction heating furnace ?

The user must first provide the site map and some requirements or technical parameters of the site. The detailed site installation layout plan is designed by our company. 2. The equipment requirements for the foundation: flat cement floor, no need to be fixed or fixed.

3. The equipment should be placed in a ventilated, back-yang, cool outdoor place;

4. The user is responsible for the equipment installation materials and the required civil engineering and necessary tools. We will guide the installation and commissioning on site and conduct on-site operation training.

5. If the user has special requirements, it can be agreed upon by the supplier and the buyer at the time of ordering.

6. Bar requirements

Bars with a diameter of 20 or more use medium frequency forging furnaces : heating is carried out along the surface of the bar when induction heating, the higher the frequency, the shallower the heating depth, the lower the frequency, the deeper the heating depth ; for example, when heating with super audio equipment , the frequency is about 50KHZ, heating depth is 2-3MM bar, the bar is required by the core portion of the heat conduction surface of the heating past; bar if the larger diameter portion of the core material is difficult to increase the temperature of the rod, and with There is a large temperature difference on the surface ; this problem can be solved by heating with intermediate frequency. The frequency of the intermediate frequency is 1KHZ-20KHZ , and the appropriate frequency is selected according to the diameter of the heating bar material to ensure uniform heating of the surface of the bar material to the core ;

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved