Bridge shell medium frequency induction heating furnace

Bridge shell medium frequency induction heating furnace Steel tube heating furnace

Steel tube heating furnace Bar intermediate frequency induction heating furnace

Bar intermediate frequency induction heating furnace 1000KW bar medium frequency induction heating furnace

1000KW bar medium frequency induction heating furnace induction metal heater

induction metal heater medium frequency induction heating machine

medium frequency induction heating machine medium frequency semi-automatic heating furnace

medium frequency semi-automatic heating furnace medium frequency induction heating furnace

medium frequency induction heating furnace medium frequency heating furnace

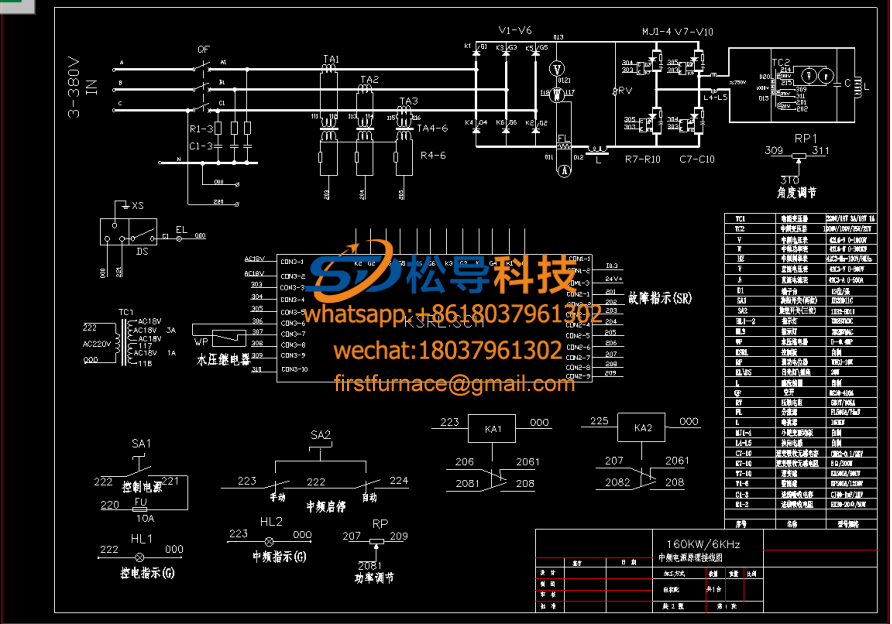

medium frequency heating furnace 160kw medium frequency induction heating furnace electrical s

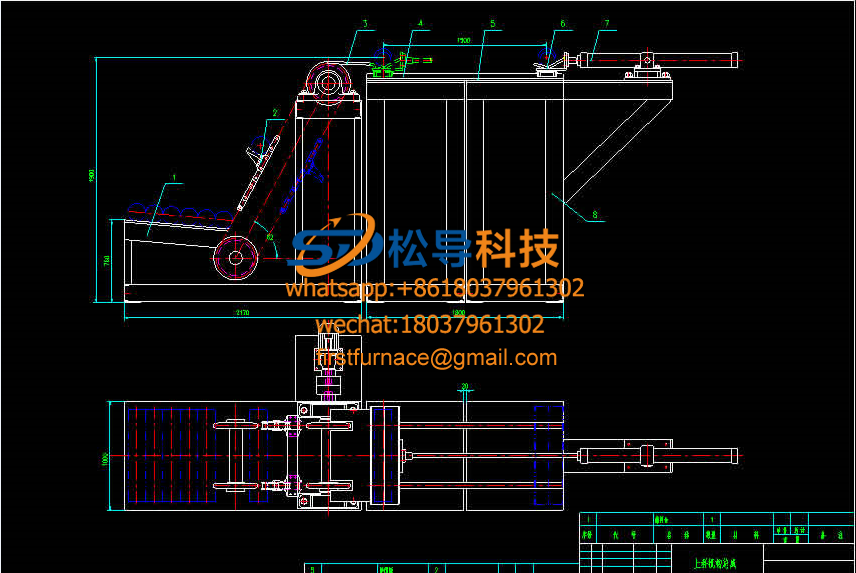

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

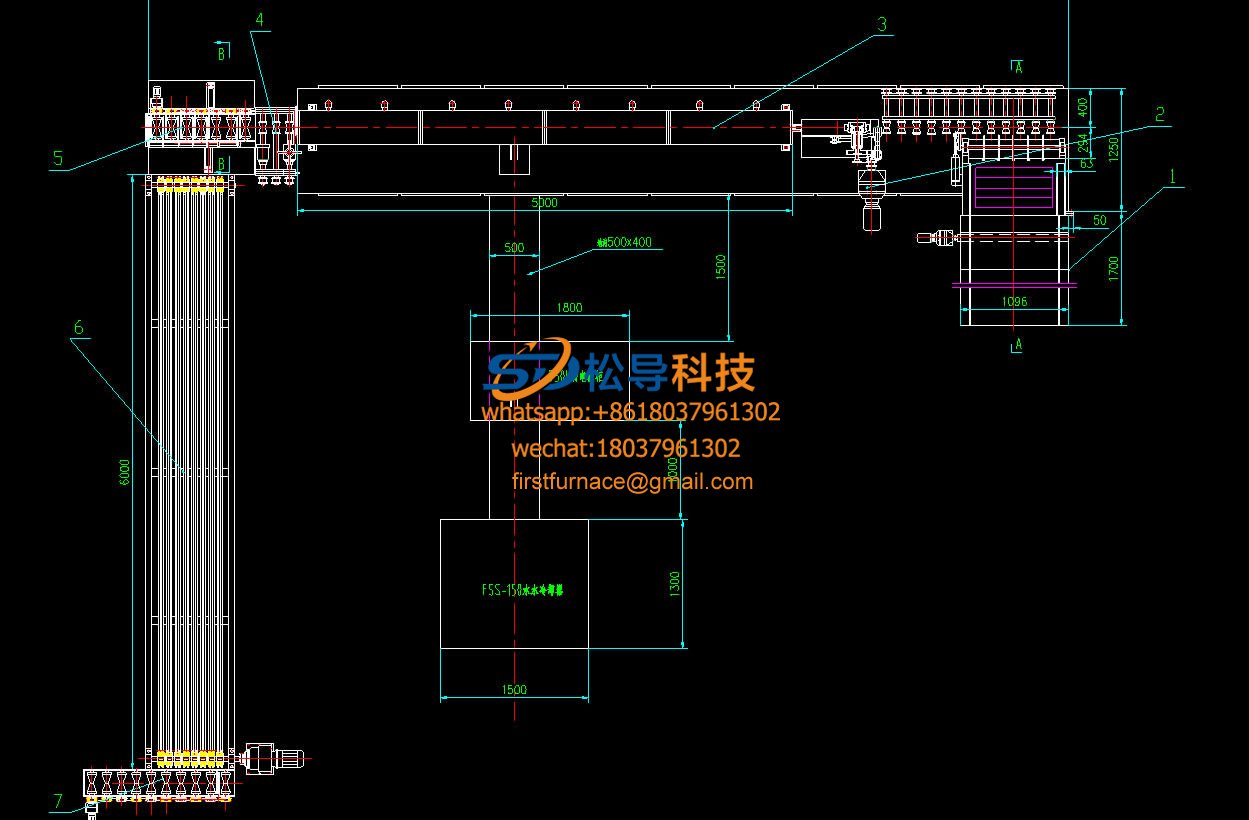

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

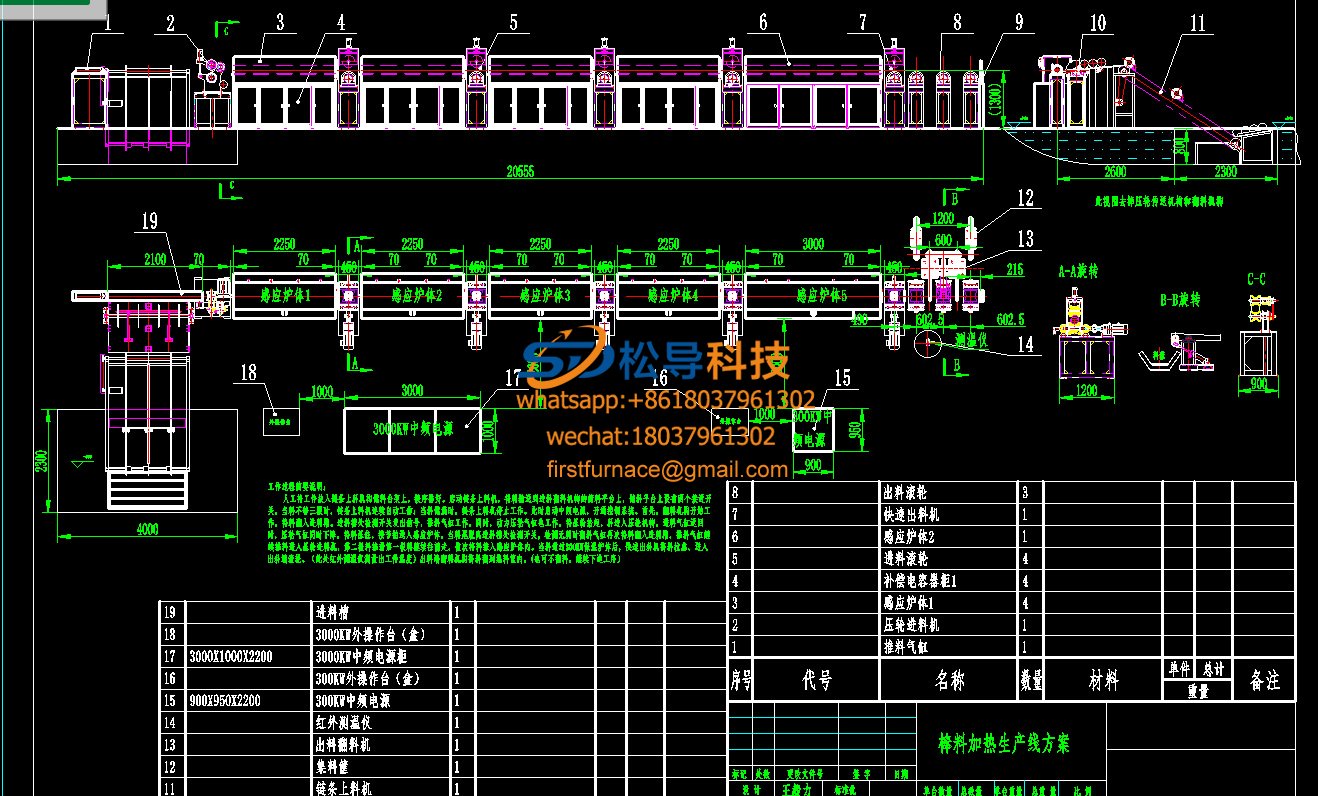

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

billet induction heating furnace coilFirst, the intermediate frequency semi-automatic heating furnace model: SD -ZP-500

Second, medium frequency semi-automatic heating furnace application: steel tube stretching, wire, steel wire heating nail; shaft, gear (sprocket), cam, chuck, fixture, etc. quenching; steel tube stretching, wire, stainless steel products annealing; hardware tools , hot shank twist drill, hot rolling;

Third, the introduction of intermediate frequency semi-automatic heating furnace

The intermediate frequency semi-automatic heating furnace uses an automatic device. If the internal load of the sensor changes, the device will automatically track the resonant frequency to ensure that the machine is always at the optimal working point. Our product unit uses process curve constant temperature and rate control mode or constant output current, constant output power control mode, even if the internal load of the sensor changes, the device always maintains the output set value. When the induction heater inputs three-phase AC voltage fluctuations, our products can automatically control the output to stabilize. The product is IGBT inverter, all digital precision control, can ensure that the IGBT is always working under various conditions.

Fourth, the intermediate frequency semi-automatic heating furnace technical advantages:

1. Adopt international famous company Siemens IGBT power device and unique inverter technology, 100% load continuation rate design, 24 hours operation under maximum power , high reliability guarantee;

2 , the self-control type can adjust the heating time, heating power, holding time, holding power and cooling time; greatly improve the quality of heating products and the repeatability of heating, simplifying the operation technology of workers;

3 , the equipment is light in weight, small in size, simple to install, connected to 380V three-phase power, water, water, can be completed in a few minutes;

4 , the footprint is very small, easy to operate, can be learned in a few minutes;

5 , especially safe, the output voltage is lower than 36V , eliminating the danger of high voltage electric shock;

6 , the heating efficiency is up to 90% , the energy consumption is only 20% - 30% of the high frequency of the old-fashioned tube , almost no electricity in the standby state, and can work continuously for 24 hours.

Five, medium frequency semi-automatic heating furnace application range:

1. For heating metal materials for stretching, forging , embossing, etc. Such as: steel pipe stretching, wire, steel wire heating nails, etc.;

2 , for metal material heating annealing . For example, steel tube stretching, wire, stainless steel products annealing;

3 , all kinds of standard fasteners and other mechanical parts, hardware tools, hot shank twist drill, hot rolling;

4 , a variety of hardware metal parts, machined parts. Quenching such as shafts, gears (sprocket wheels), cams, collets, clamps, etc.

5 , electric kettle (electric coffee pot) heating plate welding is mainly used for brazing between stainless steel flat bottom, aluminum sheet and various shapes of electric heating tube.

Sixth, medium frequency semi-automatic heating furnace selection parameter list

model | GS-ZP-500 | input power | 500KW |

Maximum input current | 750A | Operating Voltage | 342-430V |

Oscillating frequency | 2-4KHz | Inlet water pressure | 0.2-0.5Mpa |

Water temperature protection point | 50 °C | body color | Gray + white |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved