Bridge shell medium frequency induction heating furnace

Bridge shell medium frequency induction heating furnace Steel tube heating furnace

Steel tube heating furnace Bar intermediate frequency induction heating furnace

Bar intermediate frequency induction heating furnace 1000KW bar medium frequency induction heating furnace

1000KW bar medium frequency induction heating furnace induction metal heater

induction metal heater medium frequency induction heating machine

medium frequency induction heating machine medium frequency semi-automatic heating furnace

medium frequency semi-automatic heating furnace medium frequency induction heating furnace

medium frequency induction heating furnace medium frequency heating furnace

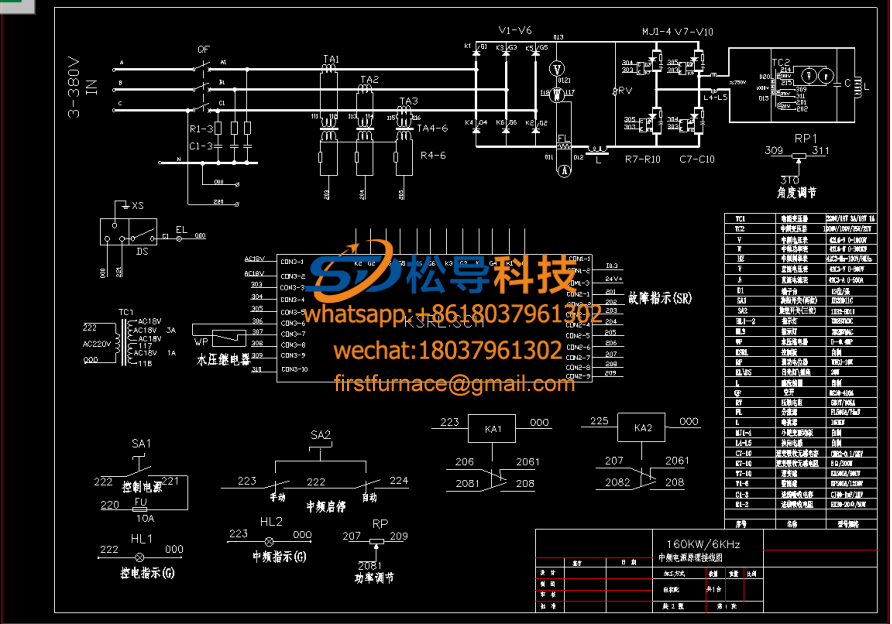

medium frequency heating furnace 160kw medium frequency induction heating furnace electrical s

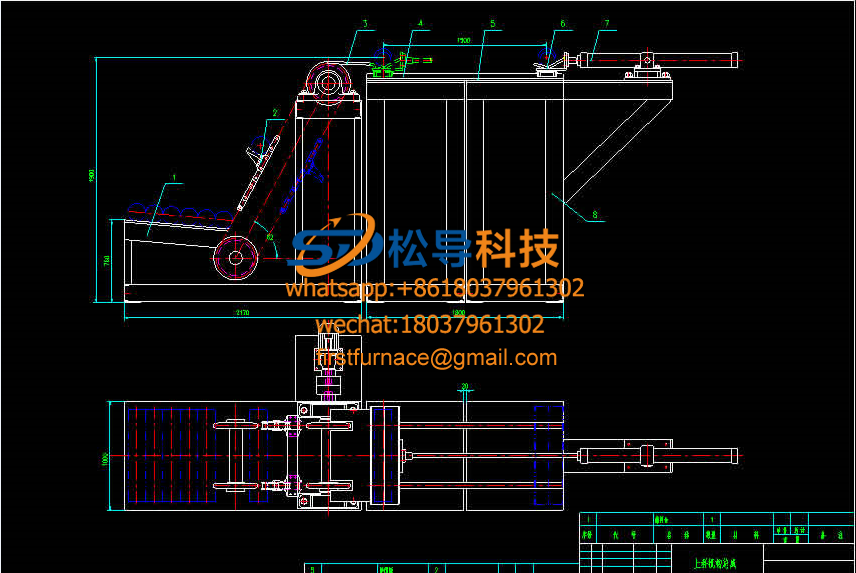

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

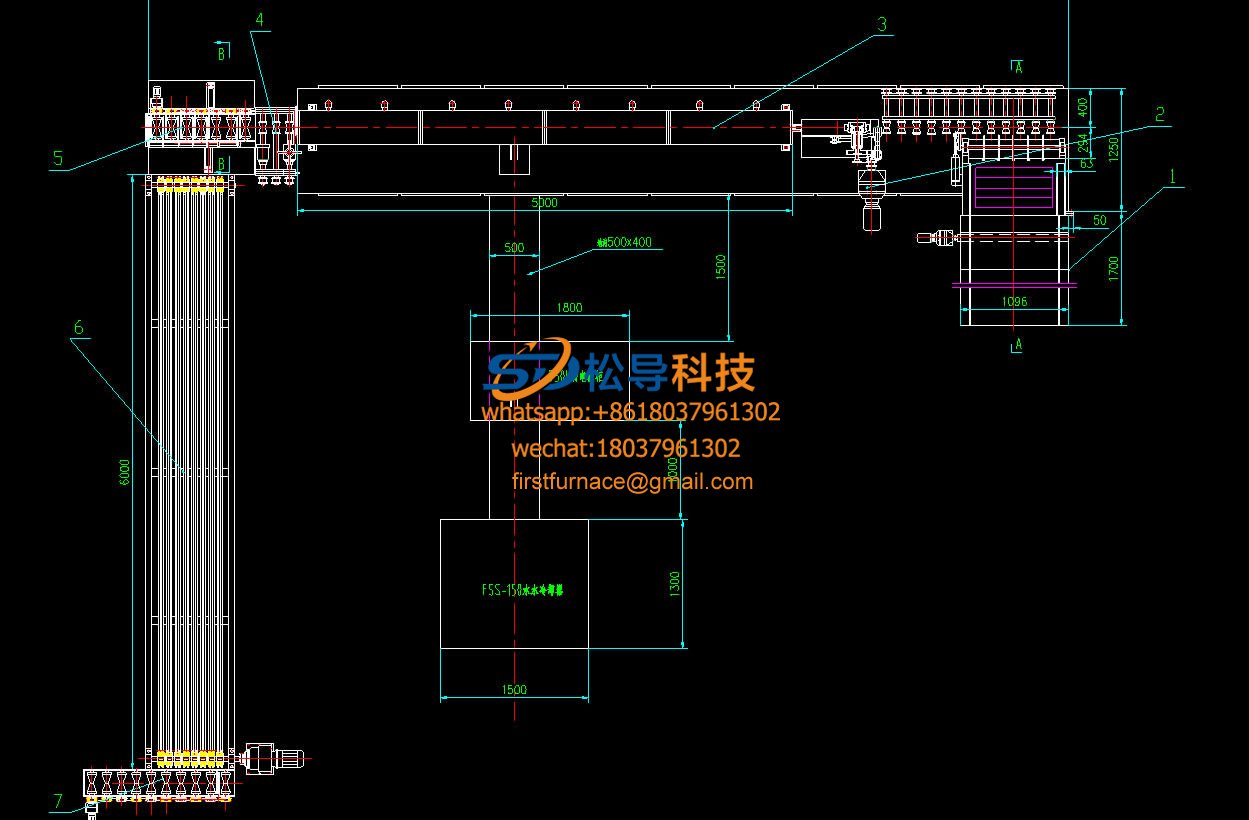

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

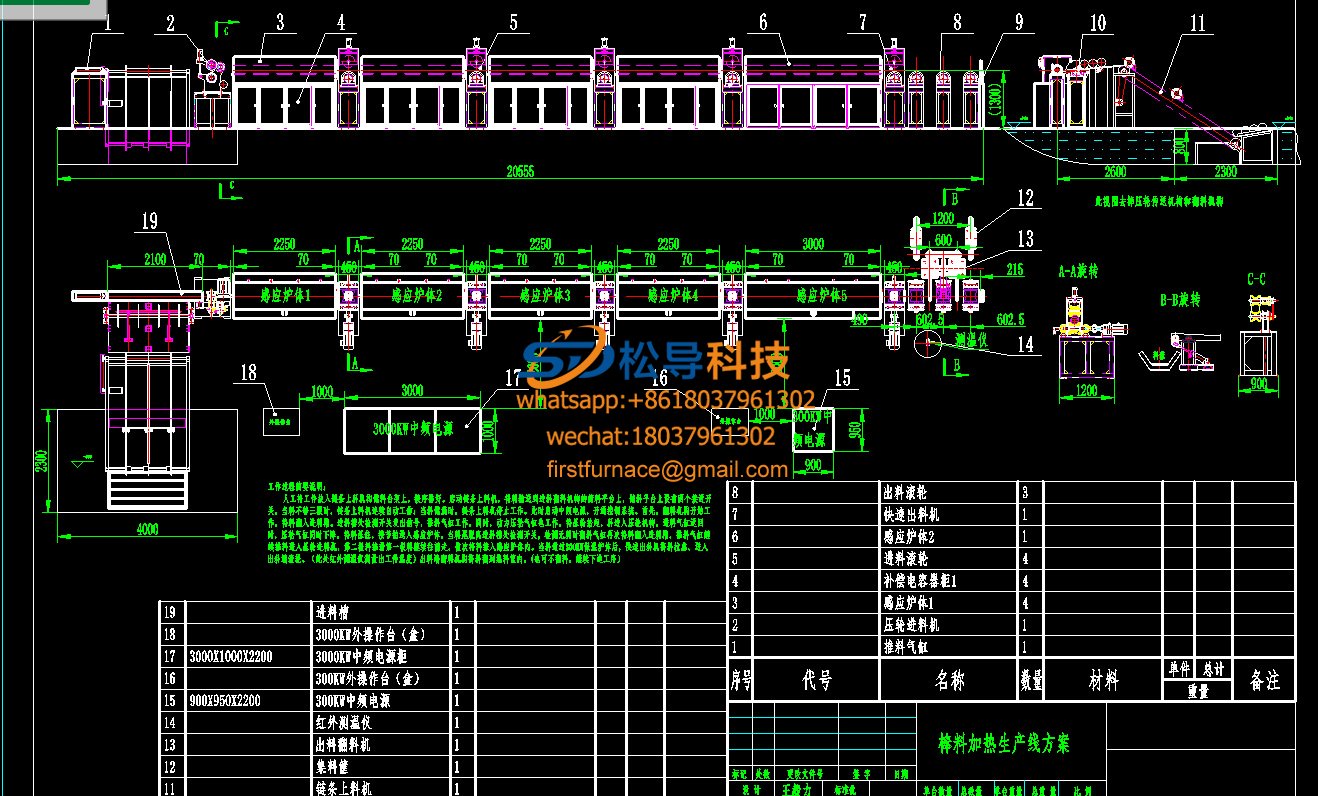

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

billet induction heating furnace coil1000KW/0.5KHZ bar medium frequency induction heating furnace

A, workpiece parameters and process requirements

1 , the workpiece size : Φ 250 ~φ 1330 , length 580 mm

2 , heating temperature: 1150 °C;

3 , production cycle: 10 minutes / piece continuously adjustable;

4 , the temperature difference of the billet after heating: longitudinal ≤ 25 °C

5 , billet monitoring shows the difference between temperature and actual billet temperature: ± 10 °C

6 , electrical efficiency of more than 90%

7. Unit energy consumption is less than 380KW.h/t

B, bar feed-frequency induction furnace with the power supply frequency determining selection:

According to the diameter of the blank , the frequency of the furnace is calculated to be 500 Hz , and the frequency of the intermediate frequency power supply is 50 0 Hz .

The required heating power is calculated to be 1000 KW based on the weight and productivity of the blank .

1000KW bar medium frequency induction heating furnace selection summary table

Serial number | content | Quantity | Remarks | |

1 | Thyristor intermediate frequency inverter KGPS -1000 / 0.5 | 1 set | ||

2 | Compensation capacitor 0.75 - 1 000- 0.5 S | 1 set | ||

3 | Induction heating furnace GTR 330*580 ( applicable material φ 330*580 ) | 1 set | ||

Induction heating furnace GTR 250*580 ( applicable material φ 250*580 ) | 1 set | |||

4 | Sensor stand | 1 set | ||

5 | Feeder | 1 set | ||

6 | Feeding platform and turning device | 1 set | ||

7 | Cylinder feeder | 1 set | ||

8 | Quick discharge machine | 2 sets | ||

9 | Two sorting machines | 2 sets | ||

10

| Automatic control system | 1 set | User selectable | |

10.1 | controlling software | 1 set | ||

10.2 | Programmable controller (Siemens) | 1 set | ||

10.3 | Industrial LCD Operating Screen ( MP270B ) | 1 set | ||

10.4 | Two-color infrared thermometer (US R aytek) | 1 set | ||

10.5 | Photoelectric switch (Japan OMRON ) | 1 set | ||

10.6 | Proximity switch (Japan OMRON ) | 1 set | ||

1 0 .7 | Temperature display | 1 set | ||

11 | External control console | 1 set | ||

12 | Connecting copper bars between devices | 1 set | ||

C, bar medium frequency induction heating furnace composition and use method :

1, the feed rod-frequency induction heating furnace method: after the sawing machine feed, by the traffic to the next good material feeder, the discharge into the buffer means, when receiving a signal lack of material feeding device, feed on the feeder Enter a blank. The billet is then pushed into the heating furnace by the cylinder pushing device for heating. After the heated billet is discharged from the furnace mouth, the signal is outputted by detecting the photoelectric switch, and the fast discharge machine and the infrared temperature measuring system work simultaneously. The blank is lifted by a quick discharge machine and sent to a two-position sorting machine for sorting. Under-temperature and over-temperature materials enter the unqualified bin. The qualified material is turned over to the feeding feeder via the turning mechanism, and the material is fed into the press in cooperation with the user's own robot.

The first roller of the quick discharge machine is designed as a hexagonal roller. When the heat-adhesive material appears, the six-sided roller can realize the vertical movement of the discharge and open the bonding portion. This can effectively solve the problem of sticking.

When the blank on the discharge device is too small and the position of the proximity switch is not detected, an audible and visual signal will be provided to inform the loading.

When the photoelectric switch of the feeder detects the shortage of material for 30 seconds, if there is still no follow-up incoming material, the control system automatically reduces the power of the intermediate frequency power supply to enter the insulation power to prevent the furnace material from being melted. When the subsequent material comes again, the system returns to normal operation.

The complete set of equipment is automatically controlled by the PLC and has a manual automatic transfer switch.

Main components and technical features of the equipment

1 , medium frequency power supply

2 , medium frequency resonant capacitor

3 , heating furnace body:

4 , automatic control system

5 , rectifier transformer: (user-supplied)

7 . Machinery:

8, the mechanism comprising: a feeder and a feed device, a fast feeder, two sorting machines.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved