S145III type top box vibration molding machine

S145III type top box vibration molding machine S146W micro-shock compaction molding machine

S146W micro-shock compaction molding machine S147W microseismic compaction molding machine

S147W microseismic compaction molding machine S148CW micro-shock compaction molding machine

S148CW micro-shock compaction molding machine S946K standard core shooter

S946K standard core shooter S947K standard core shooting machine

S947K standard core shooting machine Brake disc special core shooting machine

Brake disc special core shooting machine shell core machine

shell core machine Z95 series automatic core machine

Z95 series automatic core machine S145W micro-shock compaction molding machine

S145W micro-shock compaction molding machine S145II top box vibration molding machine

S145II top box vibration molding machine S124E single station molding machine

S124E single station molding machine S124EA single station molding machine

S124EA single station molding machine SZ145W microseismic compaction molding machine

SZ145W microseismic compaction molding machine Horizontal type hot core box doubleshot core shooting machin

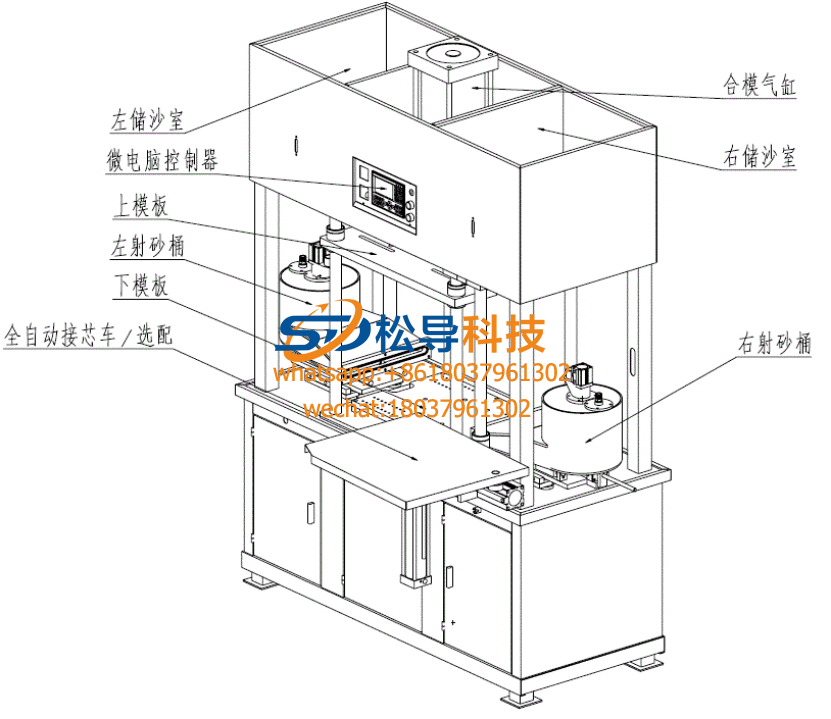

Horizontal type hot core box doubleshot core shooting machin

Use of the Horizontal type hot core box doubleshot core shooting machine:

This machine is suitable for mass production of small and medium-sized castings. It is made of micro-computer digital control. The process parameters are digitalized and automated, the use efficiency is improved, and the product quality is stable. Can play the purpose of improving quality and output. The design of the whole machine is reasonable, the function is complete, and the use is flexible and convenient.

model | Mold size mm | Template distance mm | Shot center to die distance | Molding stroke mm | Sand core weight kg | Sand bucket volume kg | Drive type | System pressure kgf | Clamping force kgf | Clamping cylinder diameter mm | Heating power kw | Automatic core |

ZRS-PC500-2-1 | 500*550 | 200-600 | 80-280 | 400 | 20 | 200x2 | pneumatic | 6 | 1600 | 160 | 16.5 | Optional |

ZRS-PC600-2-1 | 600*650 | 200-600 | 80-300 | 400 | 25 | 250x2 | pneumatic | 6 | 2500 | 200 | 21x2 | Optional |

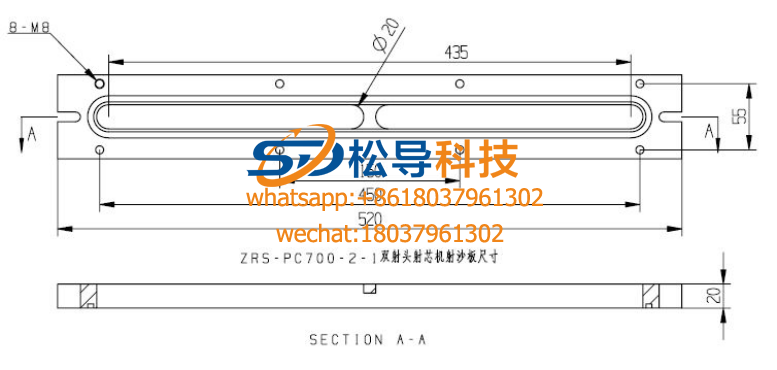

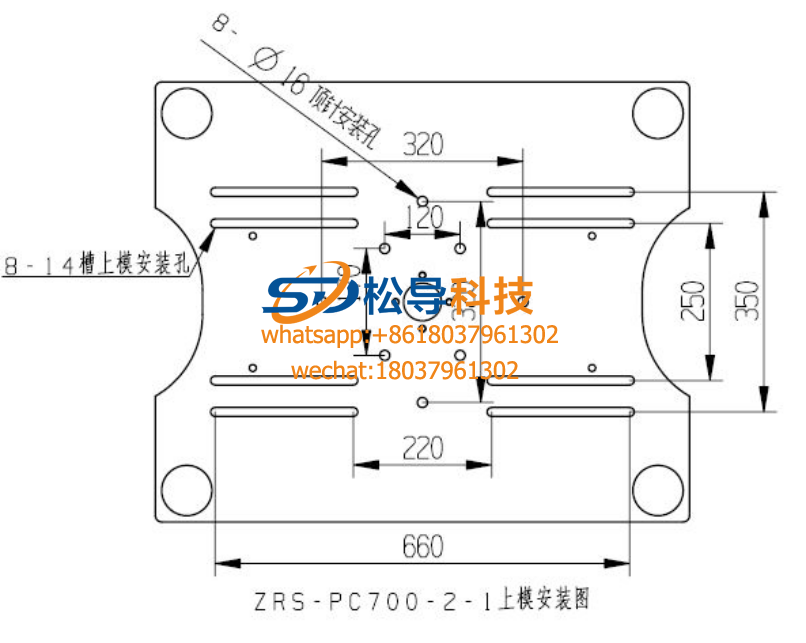

ZRS-PC700-2-1 | 700*750 | 250-750 | 80-300 | 500 | 30 | 300x2 | pneumatic | 6 | 2500 | 200 | 21x2 | Optional |

ZRS-PC800-2-1 | 800*850 | 250-850 | 80-350 | 600 | 35 | 350x2 | Optional | 6 | Optional | Optional | 25x2 | Optional |

ZRS-PC900-2-1 | 900x950 | 250-850 | 80-350 | 600 | 40 | 400x2 | Optional | 6 | Optional | Optional | 25x2 | Optional |

1: This machine consists of the fuselage, sand storage room, sanding bucket, upper template, lower template, core control, computer controller, heating circuit, and pneumatic piping system.

2: The fuselage consists of a solid steel frame, the upper part supports the sand storage room, and the lower part is a cavity molding mechanism. The inside of the fuselage is provided with a gas storage tank, a control valve installation room and an electric control cabinet.

3: The sand shooting mechanism adopts digital time control, and the time and pressure of shooting can be adjusted.

4: Pneumatic control pipeline system adopts standard electronically controlled solenoid valve, and selects 24V safety voltage, which has less waste of gas source, good control effect and lower failure rate.

1: When the equipment is hoisted, it should be hung on the nose hook or evenly suspended at the four points of the fuselage base to ensure safety and then construction.

2: After the equipment is placed on the work site, the level of the work surface should be guaranteed and should not exceed 1/1000.

operation and use

operation and use(1 , mold installation)

1: Check whether the power supply and air source meet the parameter requirements before starting the machine.

2: Check if the moisture in the water filter is excluded

3: Check if the operation switch is in the closed position

4: Configure the mold according to the actual situation

5: Place the mold on the workbench and pay attention to the orientation

6: Adjust the position of the shooting bucket to align the nozzle with the mold

7: Install the upper pressure plate,

8: Check the sand in the sandblasting cylinder

(two , test machine)

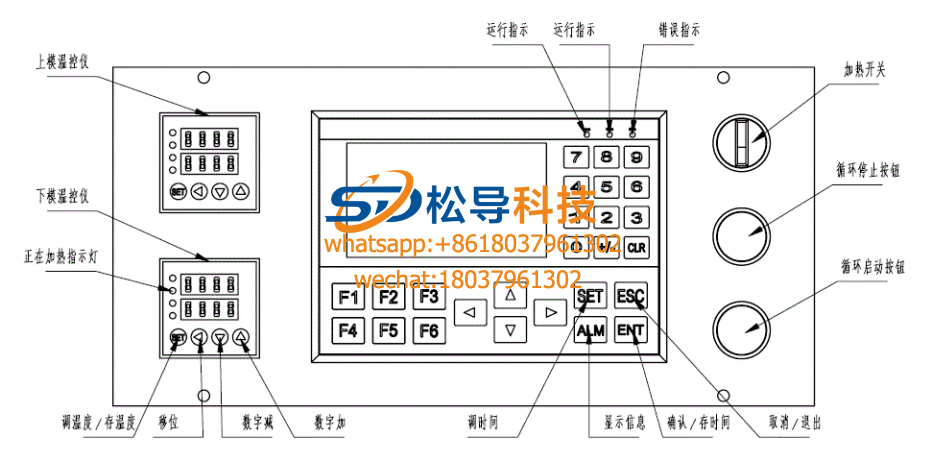

1: Adjust the parameters of the computer controller according to the process requirements

Host parameter | |||

name | Recommended value / second | Explanation | |

Zuosha | 3 | Left sand tube shooting time | |

Right sand | 3 | Right sand tube shooting time | |

Core | 3 | The time from the start of the core to the time the core is in place (set this value to 0 if the mold does not have a core pull) | |

Core | 80 | The time from the completion of the sand to the start of the core:(This value must be less than the curing time, otherwise it will open the mold and then retreat ) | |

exhaust | 4-6 | Time from the remaining air in the sand tube after shooting the sand | |

Molding | 5-9 | The time from the start of the automatic button to the closing of the mold | |

Curing | 90-300 | Time from shot sanding to mold opening (sand curing time) | |

Automatic core mechanism parameters | |||

name | Recommended value / second | Explanation | |

On the car - the car starts to enter the time | 2 | The time from the start of the core car to the time when the core car starts to enter (this parameter affects the situation when the core car enters: (the parameter is too small to easily hit the lower die) | |

Car entry - start to eject time | 4 | From the start of the core car to the time when the core car is fully in place: (The parameter is too large and the waiting time is long. If the parameter is too small, the car will start to be ejected before it is in place.) | |

Under the car - the car starts to return time | 2 | The time from the start of the core car to the time when the core car starts to exit (this parameter affects the condition when the core car exits: (the parameter is too large to hit the lower die, the parameter is too small, the product can not come out in the cavity) | |

2: Press the start switch to wait for the machine to complete automatically (Mold-Mold-Inlet-Injection-Sand-Exhaust-Unpacking-Curing-Pulling-Opening--on-car-in-out-out-under-vehicle retreat)

Serial number | name | Quantity |

1 | Injection nozzle d12 | 6 |

2 | Linear bearing LM40UU | 4 |

3 | Quick exhaust valve QE-04 | 2 |

4 | Filter WU-25 | 2 |

1: Check the water filter before going to work. If there is water, the water should be drained first.

2: Check if the heating circuit part is safe

3: This machine is equipped with automatic lubrication device. Always check whether the oil level inside the machine has oil. Please add pneumatic special white oil. If the equipment is damaged due to lack of lubricating oil, the manufacturer will not guarantee.

4: Always check the fastening screws of each part during use. If it is loose, it should be tightened in time.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved