Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro

Ф219—Ф1219 elbow epoxy powder coating anti-corrosion pro Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p

Ф720-Ф1600 steel pipe epoxy powder coating anti-corrosion p Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion

Ф219—Ф820 steel pipe epoxy powder coating anti-corrosion  Ф108—Ф1016 steel pipe epoxy powder coating anti-corros

Ф108—Ф1016 steel pipe epoxy powder coating anti-corros Φ159-Φ219 steel pipe single layer epoxy powder coating ant

Φ159-Φ219 steel pipe single layer epoxy powder coating ant Φ60-Φ273 steel pipe outer wall epoxy powder coating produc

Φ60-Φ273 steel pipe outer wall epoxy powder coating produc Φ60-Φ219 steel pipe outer wall epoxy powder coating produc

Φ60-Φ219 steel pipe outer wall epoxy powder coating produc Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi

Φ60—Φ140 steel pipe epoxy powder coating anti-corrosi Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion

Φ20—Φ32 steel pipe epoxy powder coating anti-corrosion Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying

Ф108—Ф1016 Steel Pipe Single Layer Epoxy Powder Spraying  Φ48-Φ159 steel tube epoxy powder coating anti-corrosion pro

Φ48-Φ159 steel tube epoxy powder coating anti-corrosion proFirst, the process requirements

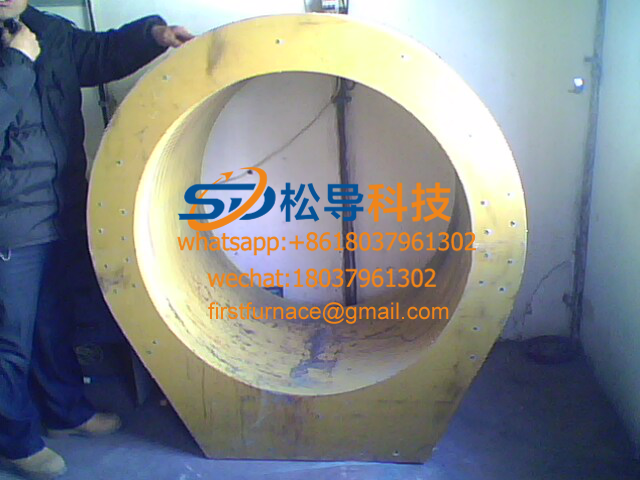

Workpiece: Φ 48- Φ 114 × 12m steel pipe

Coating requirements: epoxy powder coating 300-400 mm

Process line speed: 2-3m/ min

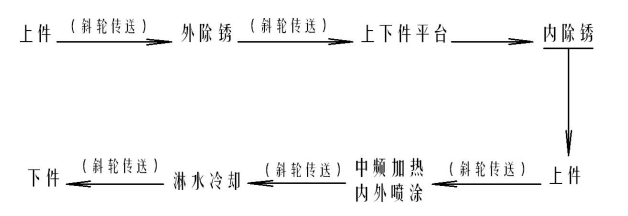

Second, the process steps

three, Coating line

The coating line adopts a slant wheel transmission type , a total of 6 sets, each set of 5 meters long. 4 single frame (including a high temperature wheel carrier transmission), power transmission using frequency control, with a control cabinet. The frequency conversion control is convenient in operation and stable in performance , and the transmission line is also equipped with a pressure tube device, so that the transmission speed of the steel pipe is stable, thereby making the sprayed layer uniform and saving raw materials. The transmission wheel adopts a pneumatic tire wheel and the Isuzu drive shaft is connected. The reducer uses a pendulum type reducer. The total length of the coating line is 34 meters .

Four . Φ 60 —Φ 140 steel pipe epoxy powder coating anti-corrosion production line medium frequency induction heating selection method :

Equipment type KGPS-400/1 | Technical indicators | |

Equipment rated power | 400KW | |

Phase voltage | 380 V | |

Rated output voltage | 750V | |

Rated output current | 800A | |

Complete configuration list: | Control panel | Model 787 2.7 |

Circuit breaker (Delixi) | DW15-1000 | |

Rectified thyristor | KP800A | |

Inverter thyristor | KK800A | |

Reactor | Ø 12 tubes, inner diameter Ø 190 | |

Manual information | One | |

Five . Φ 60 —Φ 140 steel pipe epoxy powder coating anti-corrosion production line electrostatic spraying equipment selection method :

1 , 8 gun control center DK type

Each apparatus having the above automatic gun 8, a high-pressure spray gun is built, control cabinet 8 controls automatic spray gun voltage, current and gas system, and for controlling branched venturi powder pump system for the powder.

The above device contains one set of fluidized bed powder supply system . The size of the fluidized bed : (L × W × H) 800 × 775 × 570 (mm) contains 8 venturi powder pumps.

Six . Pipe system:

Upper and lower fork tube 4, a cylinder 4 and a control system.

Seven . Secondary derusting:

The wire wheel and compressed air are used to remove rust, and the surface burrs and floating ash of the steel pipe are removed to improve the adhesion. Descaling device 1 comprises a sleeve 2 and the like protection and dust discharge cover.

Eight . Air compressor :

One six-cube screw air compressor, one 2- cubic gas storage tank, one 6- cubic air dryer , supporting gas circuit

The production line has a total length of about 34 meters. Adapted to 6 m - 12 m steel pipe coating.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved