Aluminum forging furnace

Aluminum forging furnace Aluminum rod medium frequency heating furnace

Aluminum rod medium frequency heating furnace Aluminum induction heating furnace

Aluminum induction heating furnace Aluminum hot rolling

Aluminum hot rolling Aluminum billet heating furnace

Aluminum billet heating furnace Aluminum billet induction heater

Aluminum billet induction heater aluminum alloy induction heating equipment

aluminum alloy induction heating equipment Aluminum ingot medium frequency heating furnace

Aluminum ingot medium frequency heating furnace Aluminum ingot online heating medium frequency furnace

Aluminum ingot online heating medium frequency furnace Trapezoidal aluminum ingot heating equipment

Trapezoidal aluminum ingot heating equipment Aluminum rod online heating furnace

Aluminum rod online heating furnace aluminum rod induction heating furnace

aluminum rod induction heating furnace Aluminum bar heating furnace

Aluminum bar heating furnace aluminum rod heating equipment

aluminum rod heating equipment Aluminum rod induction heating equipment

Aluminum rod induction heating equipment Aluminum bar induction heating furnace

Aluminum bar induction heating furnace Forging aluminum

Forging aluminum Alloy aluminum heating furnace

Alloy aluminum heating furnace Induction aluminum heating

Induction aluminum heating Trapezoidal aluminum ingot heating furnace

Trapezoidal aluminum ingot heating furnaceAluminum heating furnace use:

Energy-saving aluminum furnace, aluminum furnace depending on the geometry of workpieces of different materials, primarily for on-line heating, local heating, forging, extrusion, hot rolling, shearing before heating, and the entire metal material hardening, annealing, back Fire, etc.

Summary of technical parameters of aluminum heating furnace

Within 1000KW rod induction furnace power technical parameters Summary | |||||||

Rated power(KW ) | Rated frequency (HZ) | Transformer capacity (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage(V) | Power consumption (KW.h/t) | Bar diameter ( mm ) |

80 | 1000~8000 | 100 | 380v | 6 Pulse | 800 | 450 | Φ 6-35 |

100 | 1000~8000 | 160 | 380v | 6 Pulse | 800 | 450 | Φ 25-40 |

120 | 1000~8000 | 200 | 380v | 6 Pulse | 800 | 450 | Φ 30-50 |

160 | 1000~8000 | 250 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

200 | 1000~8000 | 315 | 380v | 6 Pulse | 800 | 450 | Φ 40-60 |

250 | 1000~8000 | 400 | 380v | 6 Pulse | 800 | 450 | Φ 60-80 |

350 | 1000~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

400 | 500~8000 | 500 | 380v | 6 Pulse | 800 | 450 | Φ 80-120 |

500 | 500~8000 | 630 | 380v | 6 Pulse | 800 | 450 | Φ 120-150 |

1000 | 500~1000 | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

1500 | 500~1000 | 1600 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

2000 | 500~1000 | 2200 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

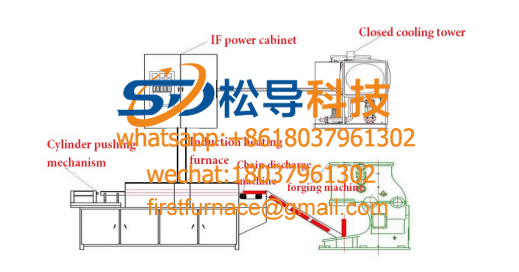

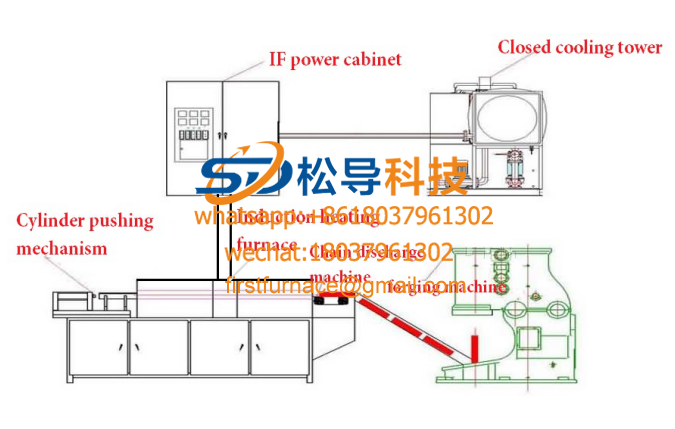

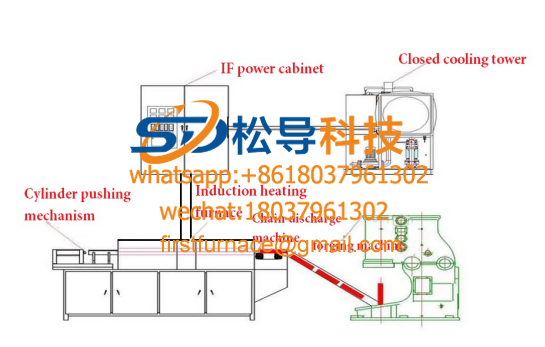

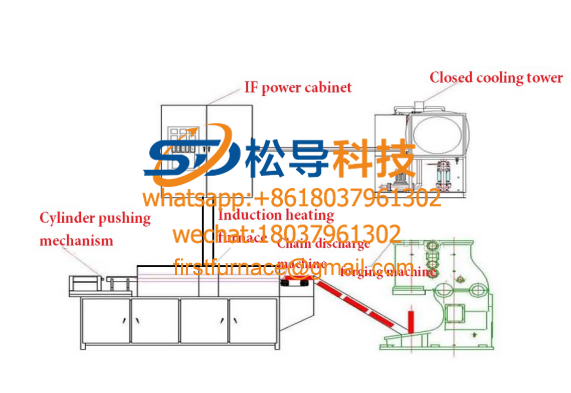

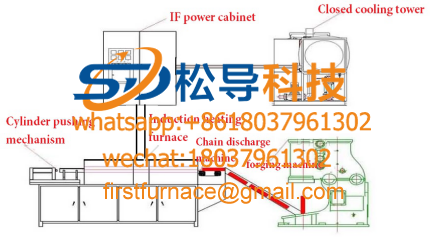

Aluminum heating furnace application assembly drawing

Aluminum heating furnace PLC intelligent control system :

1, the user needs to provide a touch screen or a remote control console

2 , man-machine interface, easy to operate

3 , real-time adjustment of equipment operating parameters

4 , real-time control of the heating process, and has a recording function

5 , different international language switching

Main features of aluminum heating furnace :

1. It is used for heating various round steels such as carbon steel and iron;

2 , medium frequency and super audio heating round steel, more heated, more uniform and faster;

3 , round bar induction heating furnace small size, easy to move, can be used with any forging and rolling equipment;

4 , the round bar induction heating furnace makes the round steel heated to the required temperature in a very short time, greatly reducing the metal oxidation, saving material and improving the forging quality;

5 , automatic feeding, automatic feeding, automatic production capacity;

6. The advantages of round bar induction heating furnace for power saving, environmental protection, cost reduction and manpower expenditure;

7 , easy to replace the sensor to adapt to the different requirements of the overall heating or end heating of round steel

Aluminum heating furnace price:

The price of aluminum heating furnace is about 10,000 yuan per unit, and there are several tens of thousands of expensive. The price of aluminum heating furnaces is affected by many factors, such as brand, category, specifications, market and so on. It is necessary to understand and compare in many aspects before choosing to buy.

Aluminum heating furnace advantages:

1. The aluminum heating furnace is continuously summarized by our engineering and technical personnel for many years of production experience, and a new generation of energy-saving induction heating equipment is introduced;

2 , a full set of aluminum heating furnace consists of only one furnace body, with a small footprint;

3 , mechatronics design, medium frequency voltage double voltage output, output slot width copper bus small gap design, reduce line power loss, power saving up to 10 % -15 %;

4 , aluminum heating furnace body through double insulation treatment to improve equipment life and reliability, high energy conversion efficiency, energy saving and consumption reduction effect;

5 , fast heating speed, high production efficiency, less oxidative decarburization, saving materials and costs, and prolonging the life of the mold;

6. Excellent working environment, improve workers' working environment and company image, no pollution, low energy consumption;

7. Uniform heating, high temperature control precision, and automatic production;

8. Easy replacement of induction furnace: The furnace body adopts rapid replacement design, which reduces production standby time and improves production efficiency.

PREV:No More Articles.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved