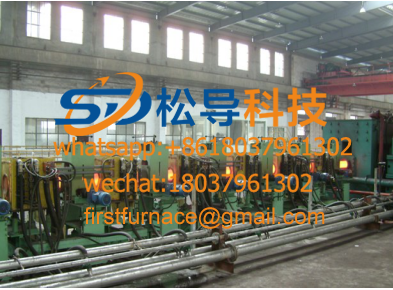

Tubing end induction heating equipment

Tubing end induction heating equipment steel pipe induction heating equipment

steel pipe induction heating equipment Steel tube induction heating furnace

Steel tube induction heating furnace Steel pipe medium frequency heating furnace

Steel pipe medium frequency heating furnace steel pipe heating equipment

steel pipe heating equipment Steel pipe induction heating equipment

Steel pipe induction heating equipment Drill rod end intermediate frequency heating equipment

Drill rod end intermediate frequency heating equipment Steel pipe online heating equipment

Steel pipe online heating equipment Steel pipe electric heating equipment

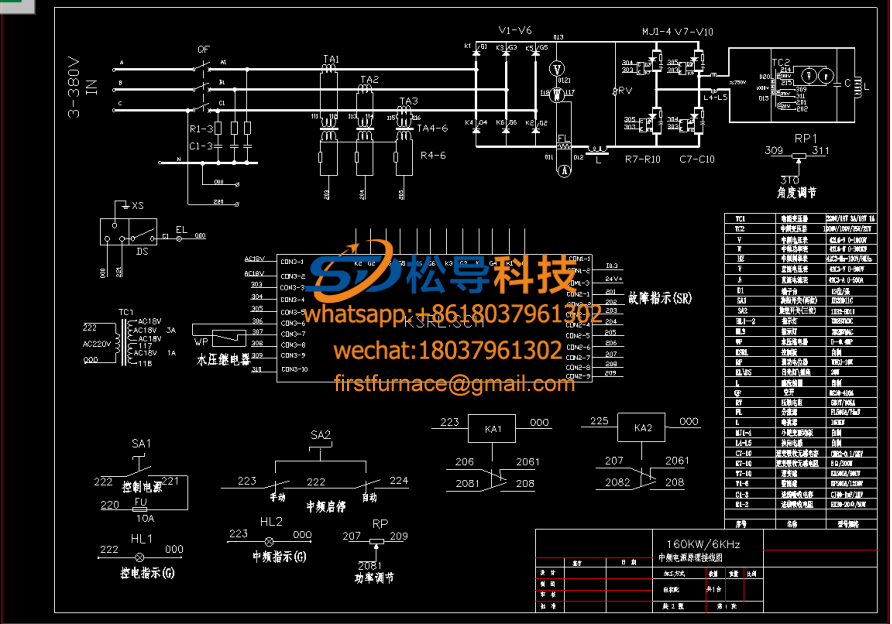

Steel pipe electric heating equipment 160kw medium frequency induction heating furnace electrical s

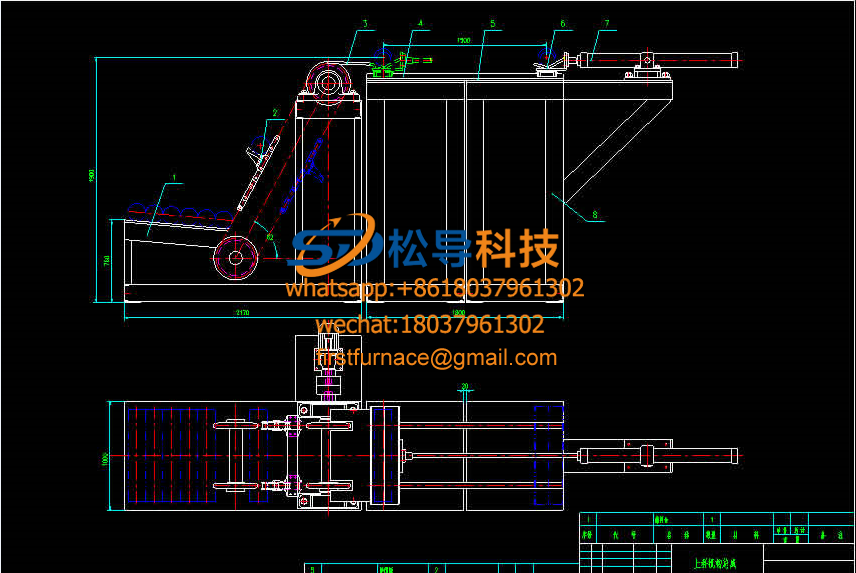

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

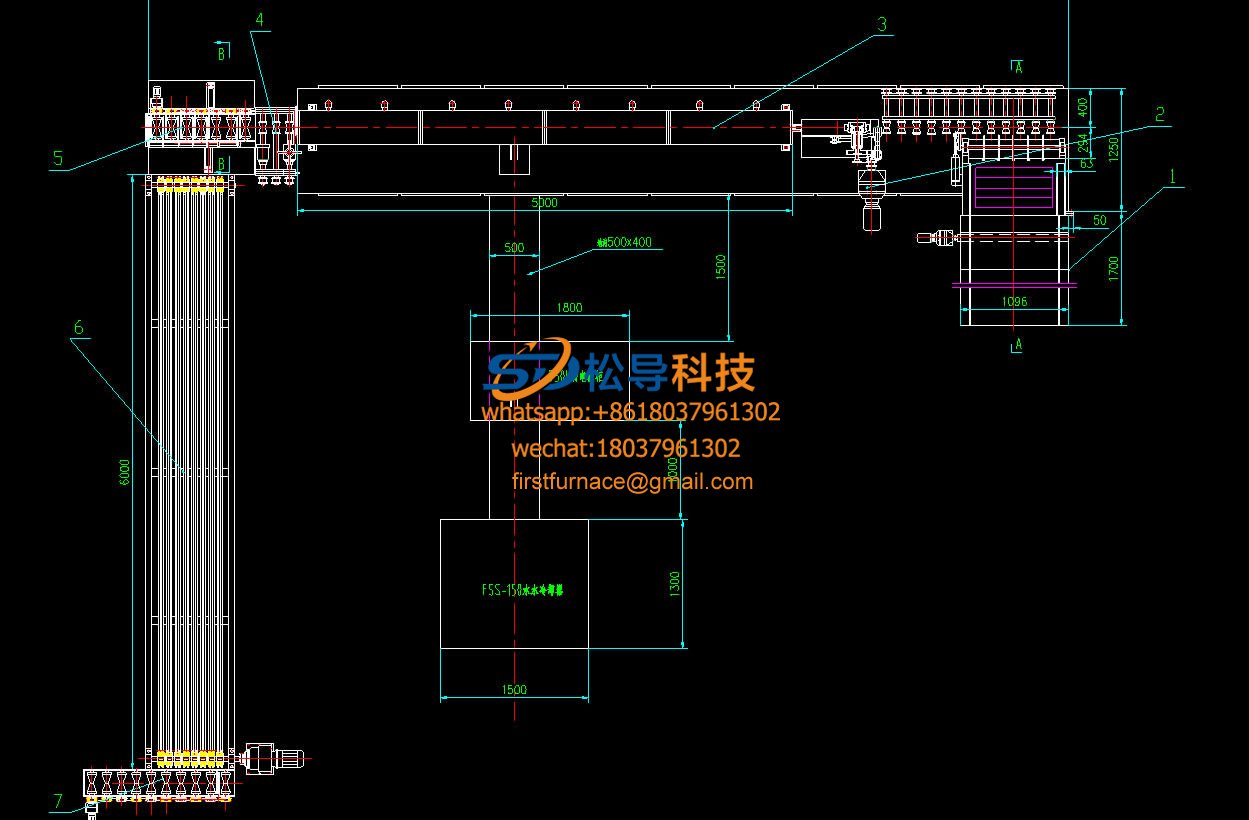

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

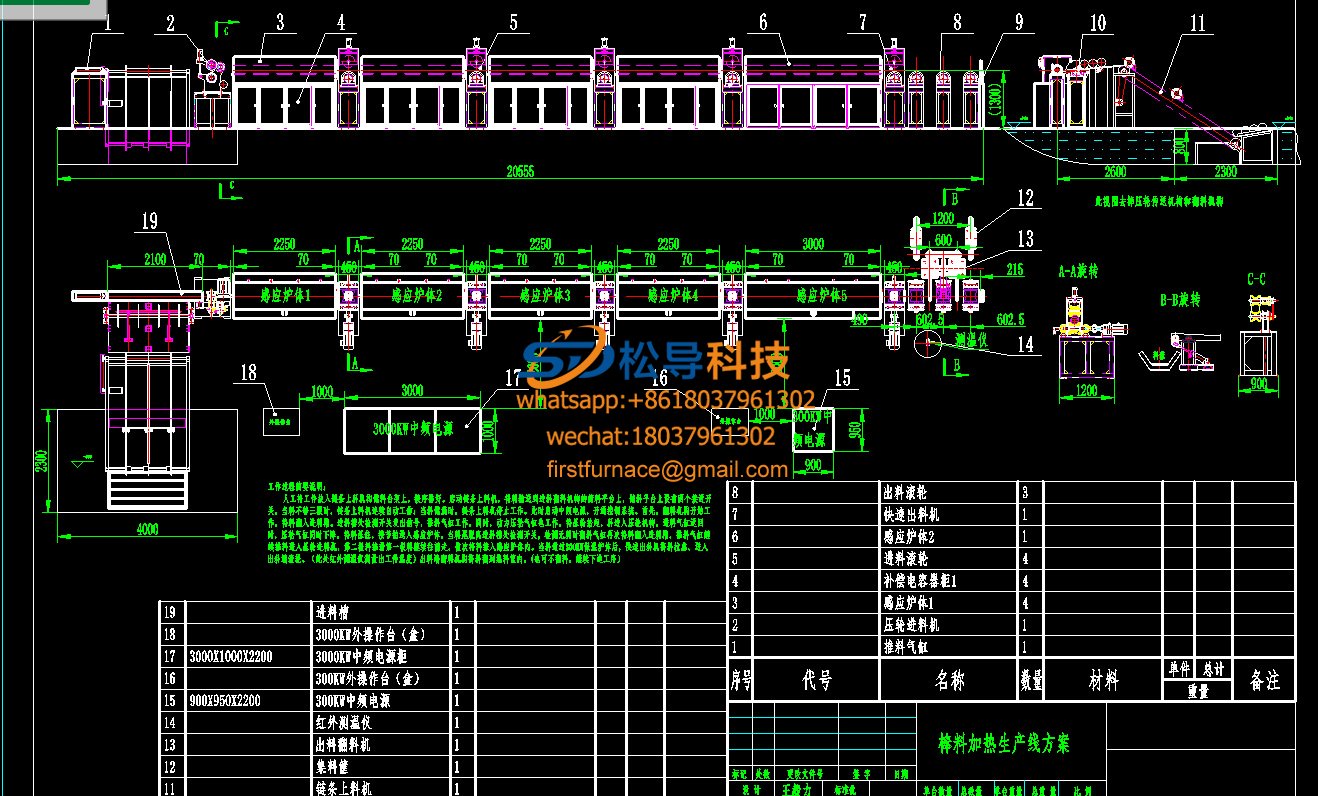

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

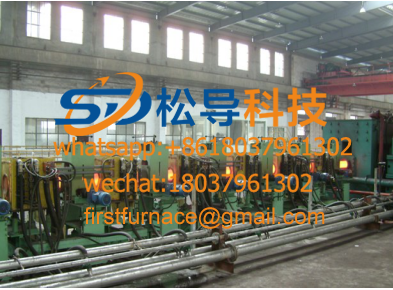

billet induction heating furnace coilSteel pipe online heating equipment is mainly used for online heating of steel pipes;

The steel pipe online heating equipment has a total power of 4500 KW. A total of 3 units, each 1500KW.

Heating steel pipe parameters:

Steel grade: 20G, 15CrMoG, 25MnG, 12Cr1MoVG, T12, T22, T23, T91, 3Cr, 9Cr, Super13Cr

Steel pipe outer diameter: Φ95~130mm

Steel pipe wall thickness: 3.0~8mm

Length of steel pipe: 8~18m,

Steel pipe passing speed: 0.5~1.2m/s.

Incoming steel pipe temperature: 700~800 degrees

After heating, the temperature of the steel pipe: 950~1000 degrees

Steel pipe online heating equipment parameters and technical requirements

The total power of the equipment is 4500kw and the frequency is 1000Hz.

Inlet water temperature 5~35° °C;

The outlet water temperature is less than 55 ° ° C;

Water pressure 0.3~0.4Mpa;

Water quality: no impurities, softened water

Water consumption: 150 cubic meters / hour; (Part A net water requirements)

PH value requirements: 6-9;

Input power: 6000KVA;

Input voltage: 10KVA

Indoor installation, equipment grounding is good, the color of the grounding wire is obviously different from the control line (the color of the grounding wire is yellow), the cross-sectional area is >4mm2, and the grounding resistance is not more than 4Ω;

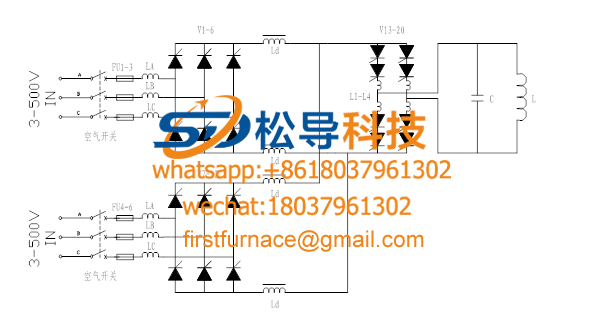

The main circuit principle of the medium frequency power supply of the steel tube heating furnace is shown in the following figure.

1, the characteristics of the medium-frequency power supply of steel pipe online heating equipment

This system is designed and used in China with advanced level of sweeping constant power and impact resistant medium frequency power supply. Its main features are as follows:

A, the control system is fully digital, no relay control

B, unique sweeping start mode with 100% startup success rate

C, regulator with fast response characteristics

D, power supply constant power output, can guarantee high power factor

E, perfect and reliable protection

F, advanced phase sequence self-identification function

G, rich external control interface

H, debugging and maintenance is simple and convenient

2, IF resonant capacitor cabinet

The intermediate frequency resonant capacitors of this capacitor cabinet are all selected from the electric heating capacitors produced by Xinanjiang Power Capacitor Factory, the model is RFM2-1.0 -2000-1.0S. Its capacity is 2000KVar and its frequency of use is 1000Hz.

3, water-cooled cable

The connector of the water-cooled cable has a detachable structure and can be easily disassembled. The inside is connected to the copper strand by soldering. This way the connection is firm and the contact resistance is small.

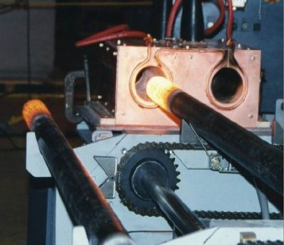

, 4, sensor

4.1. The steel pipe online heating equipment body is divided into two sets according to Φ95-110 and Φ110-130 steel pipes of different specifications, each set of 6 sets, a total of 12 sets.

4.2. In order to reduce the magnetic flux leakage, ensure that the intermediate frequency power supply is not disturbed by the magnetic field and the roller table and the support frame between the furnace bodies are not heated, the front and rear pressure plates of the furnace body adopt the special structure invented by our company, and the front and rear furnace plate materials of the furnace body are adopted. The copper plate is closed and the water is specially designed on the circumference of the furnace mouth.

4.3 The lining is integrally knotted and can be used up to temperatures above 1700 °C with good insulation, heat insulation, chilling heat and impact resistance.

5, steel pipe online heating equipment steel pipe centering device

In order to prevent the steel pipe from damaging the sensor when it passes through the induction furnace, the inductor is damaged. At the inlet end of the inductor, a centering device with a power upper and lower clamping rod is arranged to adapt to different specifications of the heating steel tube, and the speed adjustment adopts a frequency conversion motor and a frequency converter. .

6, speed measuring device

6.1 is used to detect the speed of the pipe, and calculate the given power according to the specifications of the given steel pipe.

6.2 When the pipe temperature exceeds the maximum set value, the power supply has an automatic power-off function. (Party B is responsible for the implementation and delivery of this function)

7, steel pipe online heating equipment removal device

When the heating of the steel pipe is not required, the heating furnace is manually removed from the production line and the moving distance is greater than 800 mm. (The furnace body in parallel with the descaling cylinder is removed by a distance of 2000 mm or more)

8, steel pipe online heating equipment outside the console

The operator station should have the following features:

8.1. DC voltage (shown at the head)

8.2. DC current (head display)

8.3 power (head display)

8.4. Fault alarm (signal light)

8.5. Manual / automatic transfer switch

8.6. Temperature (digital display)

8.7. Remote control of the start/stop of the IF power supply

8.8. Speed (digital display) (optional)

9, the main components and functions of the automatic control system for steel pipe online heating equipment

, a, Advantech industrial control computer

b, a set of industrial control configuration software (MCGS system)

c, a set of programmable controllers (SIEMENS SIMATIC S7-300)

d, infrared thermometer (United States Leitai) 2 sets

e, photoelectric switch (Omron)

g, operation console

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved