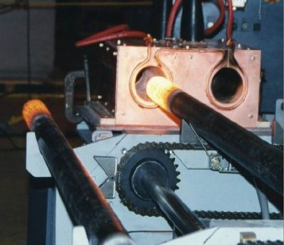

Tubing end induction heating equipment

Tubing end induction heating equipment steel pipe induction heating equipment

steel pipe induction heating equipment Steel tube induction heating furnace

Steel tube induction heating furnace Steel pipe medium frequency heating furnace

Steel pipe medium frequency heating furnace steel pipe heating equipment

steel pipe heating equipment Steel pipe induction heating equipment

Steel pipe induction heating equipment Drill rod end intermediate frequency heating equipment

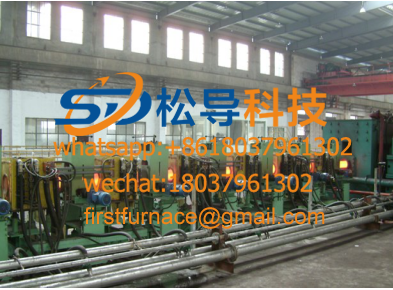

Drill rod end intermediate frequency heating equipment Steel pipe online heating equipment

Steel pipe online heating equipment Steel pipe electric heating equipment

Steel pipe electric heating equipmentSteel pipe medium frequency heating furnace: steel pipe heating and heat preservation, suitable for induction heating of steel pipe with diameter of 20mm-3000mm : 5mm-50mm .

Steel pipe intermediate frequency heating furnace parameters summary:

diameter | Control System | Power supply |

Φ 18-28mm | PLC intelligent control system | KGPS 200KW |

Φ 30-70mm | PLC intelligent control system | KGPS 350KW |

Φ 80-110mm | PLC intelligent control system | KGPS 500KW |

Φ 16-32mm | PLC intelligent control system | KGPS 200KW |

Customized production of steel pipe intermediate frequency heating furnace according to customers' actual needs | ||

Steel pipe medium frequency heating furnace PLC intelligent control system :

1, the user needs to provide a touch screen or a remote control console

2 , man-machine interface, easy to operate

3 , real-time adjustment of equipment operating parameters

4 , real-time control of the heating process, and has a recording function

5 , different international language switching

Steel pipe medium frequency heating furnace has characteristics:

1. Medium frequency power control, infrared thermometer control, non-contact heating , which makes the workpiece heating more uniform.

2 , steel pipe medium frequency heating furnace closed-loop control, heating speed, high production efficiency.

3. All the water pipelines of the induction furnace body are made of 304 stainless steel pipes to avoid water rust and scale, greatly improve the cooling effect and long service life.

4 , steel pipe medium frequency heating furnace adopts man-machine interface PLC control system, full touch screen control whole set of induction heat treatment equipment production.

5 , high temperature control accuracy, fully automatic intelligent control.

6, the IF steel furnace polluting, low energy consumption, no cracks processed workpieces, toughness and tensile strength linearity requirements to achieve customer satisfaction.

7, the IF steel furnace conveyor drive output system controlled by an independent, automatic control of the cylinder, the speed control segment.

8. A powerful formula management system, after selecting the steel grade and plate type parameters to be produced, automatically call the relevant parameters.

9, the IF steel furnace with closed cooling tower for cooling, energy saving.

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved