Aluminum forging furnace

Aluminum forging furnace Aluminum rod medium frequency heating furnace

Aluminum rod medium frequency heating furnace Aluminum induction heating furnace

Aluminum induction heating furnace Aluminum hot rolling

Aluminum hot rolling Aluminum billet heating furnace

Aluminum billet heating furnace Aluminum billet induction heater

Aluminum billet induction heater aluminum alloy induction heating equipment

aluminum alloy induction heating equipment Aluminum ingot medium frequency heating furnace

Aluminum ingot medium frequency heating furnace Aluminum ingot online heating medium frequency furnace

Aluminum ingot online heating medium frequency furnace Trapezoidal aluminum ingot heating equipment

Trapezoidal aluminum ingot heating equipment Aluminum rod online heating furnace

Aluminum rod online heating furnace aluminum rod induction heating furnace

aluminum rod induction heating furnace Aluminum bar heating furnace

Aluminum bar heating furnace aluminum rod heating equipment

aluminum rod heating equipment Aluminum rod induction heating equipment

Aluminum rod induction heating equipment Aluminum bar induction heating furnace

Aluminum bar induction heating furnace Forging aluminum

Forging aluminum Alloy aluminum heating furnace

Alloy aluminum heating furnace Induction aluminum heating

Induction aluminum heating Trapezoidal aluminum ingot heating furnace

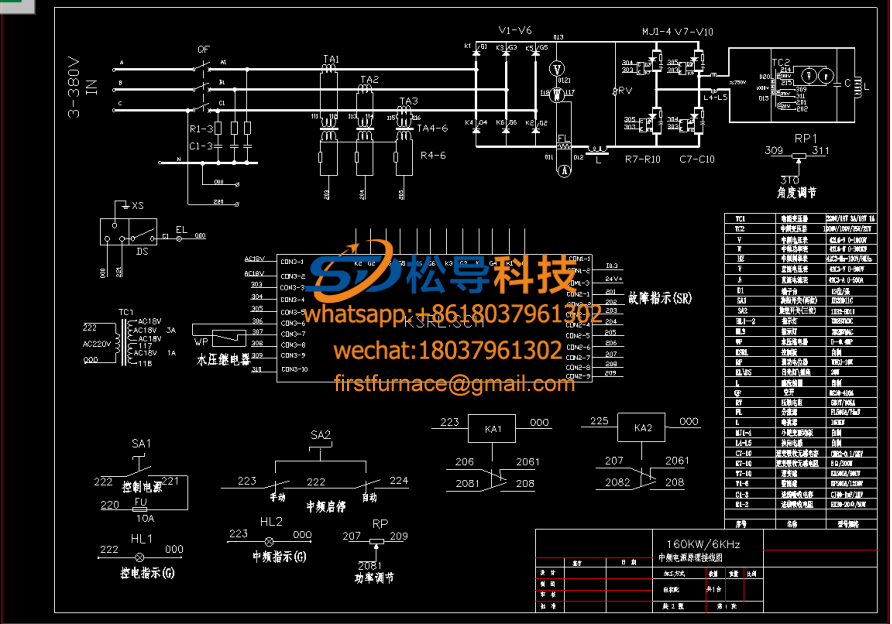

Trapezoidal aluminum ingot heating furnace 160kw medium frequency induction heating furnace electrical s

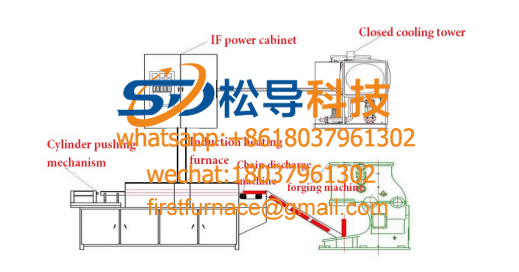

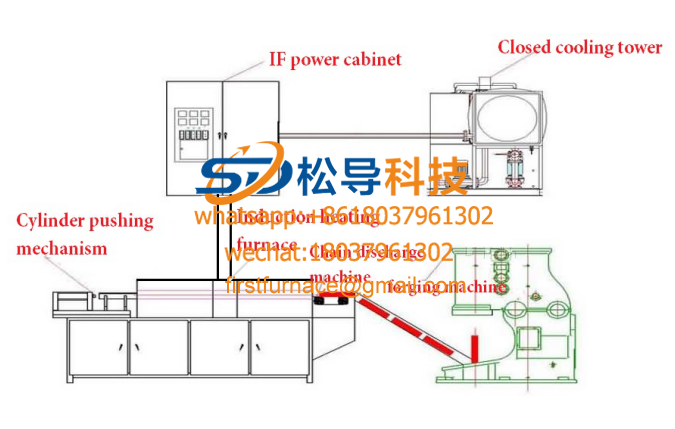

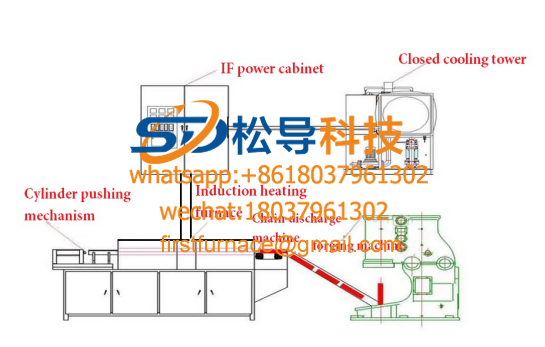

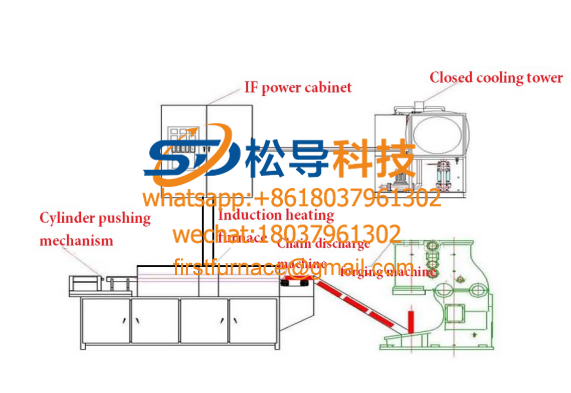

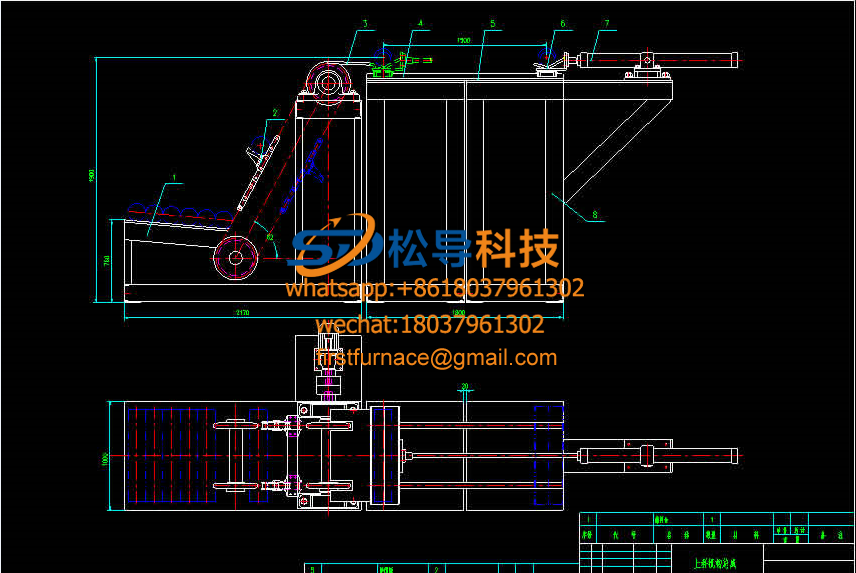

160kw medium frequency induction heating furnace electrical s Mechanical schematic diagram of automatic feeding of round st

Mechanical schematic diagram of automatic feeding of round st 20mm bar induction heating forging furnace

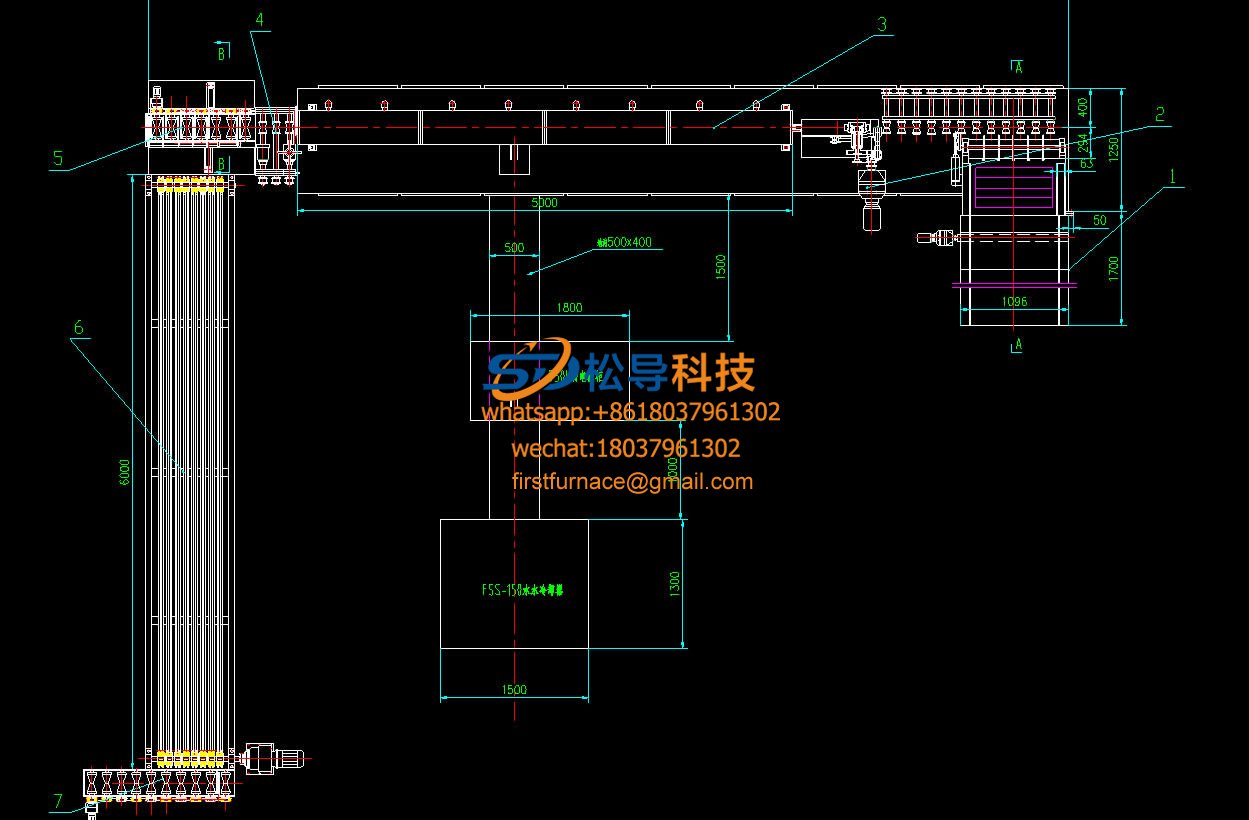

20mm bar induction heating forging furnace Bar Induction Heating Furnace Foundation Map

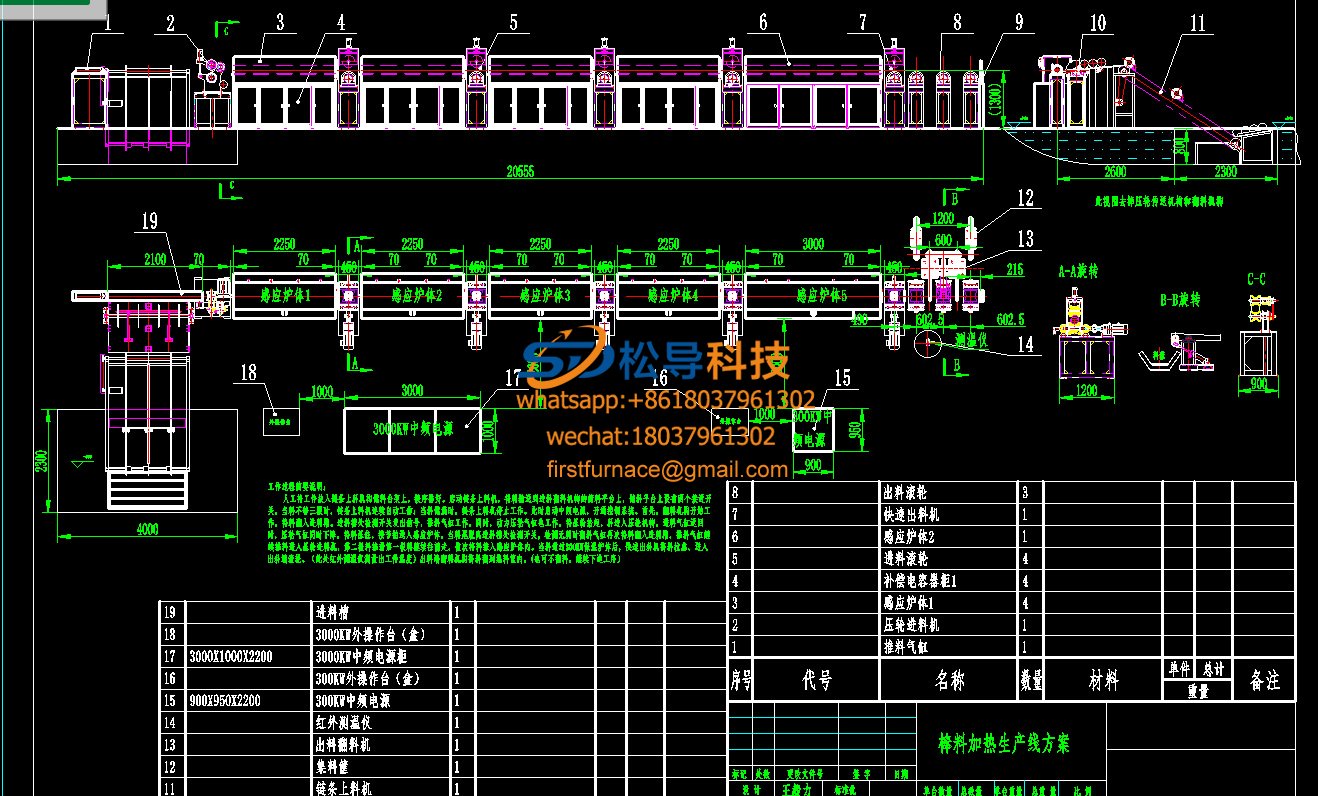

Bar Induction Heating Furnace Foundation Map Plane Layout of Intermediate Frequency Induction Heating Furn

Plane Layout of Intermediate Frequency Induction Heating Furn billet induction heating furnace coil

billet induction heating furnace coilUL+Z-1600+255/2+10 aluminum and aluminum alloy rod continuous casting and rolling production line

Features

The design concept of the fourth-generation aluminum rod continuous casting and rolling mill production line is to optimize the equipment hardware, ensure long-term stable operation of the production line, reduce operating costs, economical environmental protection and low carbon, and produce aluminum and aluminum alloy rods with better quality. The crystallization wheel of the fourth-generation four-wheel casting machine adopts the H-type reinforcing structure, which improves the service life of the crystallizing wheel. Using a drainage tube and a horizontal guide automaticpouring the molten aluminum into the mold cavity smoothly, without turbulence and the turbulence, the flow channel within intermediate Fort aluminum surface oxide film is not destroyed, again reducing the intake of liquid aluminum Oxidation ensures the quality of the aluminum rod; the rolling mill adopts 2 independent transmission frames + 10 integral transmission frames, and integrates the advantages of the aluminum alloy rolling mill and the general aluminum rolling mill in strength, which improves the strength and use of the wearing parts. Lifetime; new type of guide rod adopts quadratic curve tube roller water-filled rod forming system, patented product (patent number), no butter, no scratch, no blockage, economical and environmental protection, no pollution, can be directly used for electric aluminum rod Enameled wire and extruded tube, especially suitable for the production of aluminum and aluminum alloy rods. The production line can be electrically connected to the matching program in terms of casting speed, rolling speed, traction speed and closing speed to ensure that the production line is synchronized and fine-tuned during operation, making operation simple and convenient .

First , the use of equipment

The machine adopts continuous casting and rolling process to produce aluminum rod and aluminum alloy rod . The raw material is pure aluminum ingot , electrolytic aluminum liquid or aluminum alloy , and aluminum rod or aluminum alloy rod with diameter of Ф9.5mm and Ф12mm is produced .

Second, the equipment composition

1. Equipment Name: UL+Z-1600+255/2+10 Aluminum Rod Continuous Casting and Rolling Mill Production Line

2. Main components of the equipment: four-wheel casting machine, active front traction, rolling shearing machine, active straightening device, frequency doubled induction heating device, active feeder mechanism, 255/2+10 aluminum alloy rod rolling mill , quadratic curve tube Roller water-filled rod forming device (oil-free lead rod, active rear traction) , plum-type double-frame closing rod , rolling mill emulsion circulation device, rolling mill lubricating oil circulation device, production line electronic control system . (Note: Each set of aluminum melting furnace, holding furnace and launder is required to be ordered separately. Among them, the external cooling system of the casting machine and the cooling system of the heat exchanger are provided by the user)

Third, the simple process

1. Aluminum ingot→aluminum liquid (aluminum alloy)→aluminum liquid refining→sampling→insulation standing→filtering→casting→cooling billet→active drawing before billet cutting→(straight)→(induction heating)→active Feeding into rolling → rolling → oil-free lead rod (quenching) →(post-traction) → continuous winding rod → plum-type double-frame closing rod → strapping → finished aluminum rod metering → inspection → storage.

2, with a good molten aluminum or molten aluminum liquid (molten aluminum alloy) by a holding furnace through the flow channel, into four caster wheel, continuously cast ingot trapezoidal area of 150 0mm 2. The active ingot is sent into the rolling shear to cut the waste ingot.

(After straightening frequency induction heating temperature), the automatic feeding mechanism feeding the ingot into a trapezoidal rod rolling mill, the conic roller water and oil-free continuous primer lever about the lever, double stitch block.

Fourth, the main technical parameters of the production line selection

Production of aluminum rod diameter | Ф9.5mm , Ф12mm, Ф15mm |

Maximum theoretical production capacity | 1.6-3.5 tons / hour ( Ф 9.5mm aluminum and aluminum alloy rod) |

Main equipment size | 45 × 7.8 × 5.1 m (excluding the furnace and cooling circulation system) |

Total weight of main equipment: | 62 t (mechanical part) |

Total power | 785kw |

V. Technical description of aluminum alloy rod continuous casting and rolling production line

(1) Continuous casting machine

Crystallization wheel diameter | Ф1 6 00 mm |

Crystallized wheel form | H- shaped |

Crystallization wheel cross-sectional area | 1500 mm2 |

Ingot cross-sectionalshape | Ladder |

Motor speed | 500-1 44 0 rpm |

Casting speed | 11.7-23.4 m/min |

Crystal wheel drive motor | 5.5 kw N=1 44 0r/min (AC, variable frequency speed regulation) |

Steel belt tensioningcylinder | QGAESZ160×200L3 |

Cylinder pressure tightstrip | 10A-5 CBB100B125(RY-T) |

Pouring lift motor | Y80 2 - 4 0.75 kw N= 1390 r/min |

Cooling water pressure | 0.35-0.6 Mpa |

Cooling water volume | 60 t/h (internal cooling: 40 t/h, external cooling: 20 t/h) |

Cooling water temperature | <35°C |

(2) Active front traction and rolling shears

Front traction motor | Y132S-4 5.5kw 1440r/min |

Rolling shear motor | Y180L-6 15kw 970r/min |

Ingot cut length | 700 mm |

Rolling scissors material | W48Cr4V |

The rolling shearing machine is driven by an AC variable frequency motor, and the needle pendulum speed reducer is used for deceleration. Two rollers are mounted on the two rollers of the rolling shearing machine for rolling shearing, and the cutting length is about 700 mm. The rolling shearing machine is mainly used for cutting the ingots at the production line before the rolling and rolling, and when the equipment is faulty, it is used when there is no need to stop casting. Photoelectric positioning is placed on the rolling shear so that the blade is always stopped at a certain position.

The active front traction is located in front of the rolling shear and integrated with the rolling shear.

(3) Straightening device

There are five straight straight wheels, and the top two are installed in the following three positions.

(4) Frequency doubled induction heating device

Rolling of aluminum alloy rods requires constant spindle temperature during continuous rolling to achieve constant temperature rolling. Constant temperature rolling is a remarkable feature of rolled aluminum alloy rods.

Mainly include induction heaters, medium frequency power cabinets, temperature measurement and temperature control systems. The induction heater adopts a two-stage type with a passive support drive roller between the segments. The temperature control system consists of imported optical fiber thermometer, intelligent instrument and analog conversion system. It can adapt to the process requirements of heat treatment heating temperature before rolling of aluminum alloy ingot: the maximum temperature rise is 80 °C, and it is heated from 440 °C to 480 °C to 490 °C--520 °C; continuously adjustable to ensure the minimum temperature of the initial rolling is 510 °C.

IF power supply maximum output power | 300 kw |

IF power frequency: | 350 HZ |

Ingot heating can be heated up to the maximum | 80 °C |

Cooling water flow | > 15 t/h |

Cooling water pressure: | 0.3-0.4MPa |

Production speed | 8 -12 m/min |

Maximum output | 3.88t/h |

Equipment dimensions | 2200×1256×1000mm (L × H×B) |

( 5 ) continuous rolling mill

Type | Two rolls plus three rolls Y type |

Rod diameter | Ф9.5mm, Ф12mm |

Number of racks | 1 2 |

Roll nominal size | Ф255 mm |

Adjacent frame ratio | 1-2# 58/41 1.42 2-3# 57/42 1.36 3-4# 56/43 1.30 4-12 55/44 1.25 |

Final theoretical maximumspeed | 4 m/s ( maximum theoretical output ofФ9.5mm finish rolling 3.5 tons/hour) |

Rolling center height | 902.5 mm |

main motor power 1# rack motor 2# rack motor | Z4-3 1 5- 3 2 280 kw (DC, N= 75 0 r/min) 55kw (AC) 45kw (AC) |

Roll material | H13 |

Active feeding mechanism cylinder | CA100B75-AB(10A-5) |

(F) an oil lubricating system (lubricating system for a dual gearbox)

tank | V= 3 m3 1 |

Pump motor | Y132M2-6 5.5kw960 r/min 2 sets |

Pump model | 2CY-18/ 0.3 6- 2 Q=18m3/h P=0.3MPa 2 sets |

filter | GLQ-80 1 set |

Oil temperature | <35°C |

( 7 ) Emulsion lubrication system (cooling and lubrication dual system for aluminum rod rolling )

Lotion pump | IS100- 80 - 16 0 A Q=100m 3 /h P=0.5MPa 2 |

Pump motor | Y1 6 0M 1 -6 11 kw 2940 r/min 2 |

Cooler | BR0.35 0.6/120 35m 2 1 |

filter | GLQ-100 2 th |

( 8 ) Quadratic curve tube roller water-filled rod forming device (without butter)

1. Quadratic tube roller water bag type lead rod integration system (detailed detailed description)

2. Cooling water piping system (use emulsion when producing aluminum rods)

3. Cooling and drying system

The cooling and drying system is located at the upper end of the cooling water piping system and is mainly used to dry the remaining moisture on the surface of the rod.

3. Active traction device

Traction speed | 8.9m/s |

Traction motor | Y132N-4 7.5kw 1440r/min |

The device uses a double active pinch to adjust the pressure. The pinch roller rotates by the motor through the V-belt drive, and the other pinch roller (synchronous) is driven by the two pairs of gears, and the organic oil in the gearbox is lubricated.

5. Ring swing device

Wrench motor | 4 kw 1440r/min |

The rod penetrates the worm gear shaft in the traction thrust, and then pre-deforms under the spiral swing tube, and then wraps around the trolley frame.

6. Circle car

Ring frame diameter | Ф2000mm |

Ring frame height | 1350mm |

Round aluminum rod weight | 2.5-3t |

Copyright© 2007-2013 NO.6 Electric Mall All Rights Reserved